System Options: EasyLift

C O N F I D E N T I A L – FEI Limited Rights Data7-22

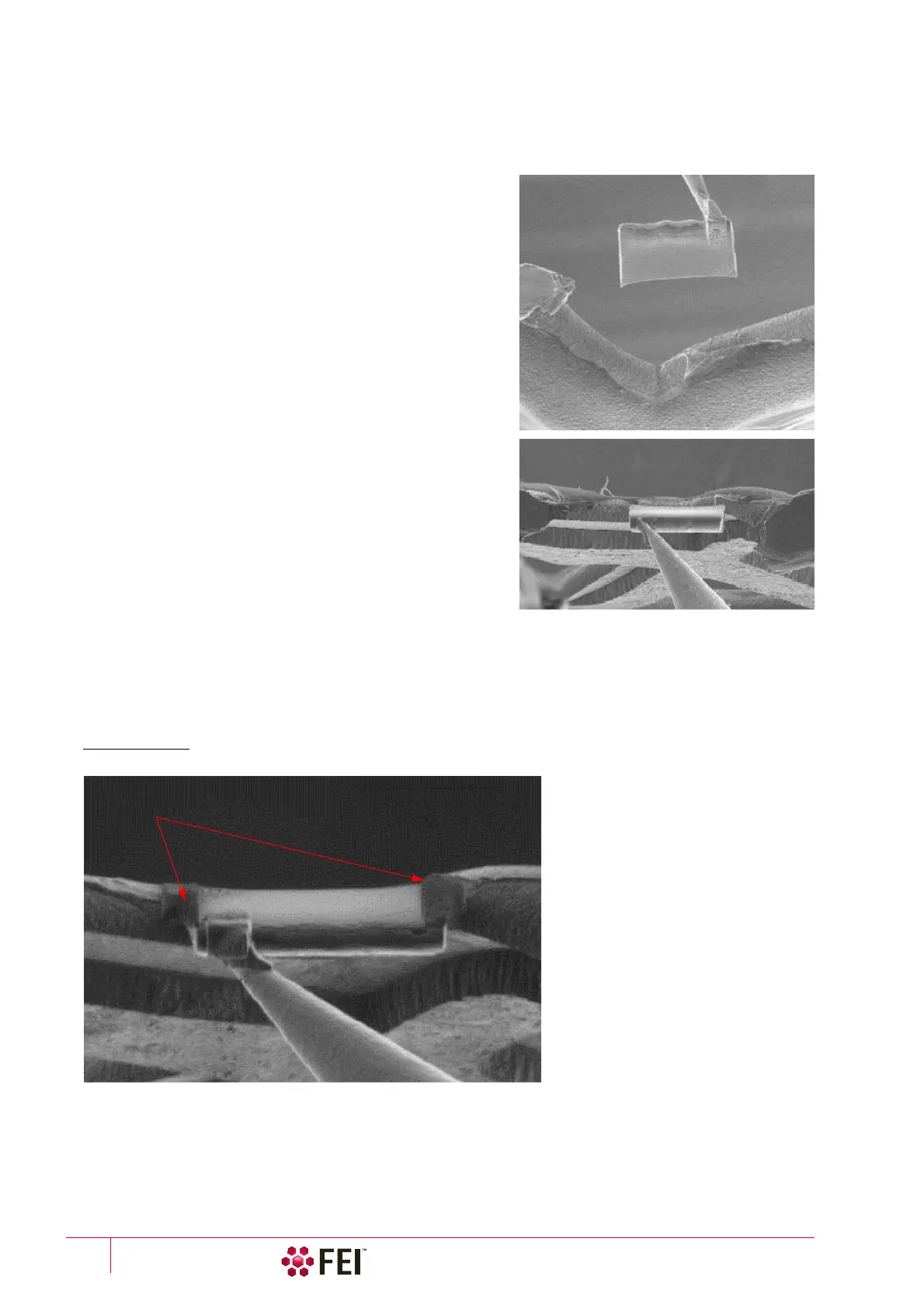

Welding the membrane to the Grid

In this procedure, the membrane is placed on the (usually copper) grid used for a TEM observation (TEM grid) and

they are welded together with tungsten or carbon.

1. Switch to the 100 pA beam current.

2. Position the stage to the TEM grid.

3. Find the eucentric position of the TEM grid spot where the

membrane will touch down.

4. Adjust the stage tilt to 0°.

5. Lower the stage by 2 mm below the eucentric position.

6. Insert Carbon or Tungsten GIS needle.

7. Insert the EasyLift needle.

8. Position the EasyLift needle tip to the eucentric position /

beams coincidence. Raise the stage up close to the eucentric

position.

9. Place the membrane inside one of the TEM grid notches by a

slow X, Y and Z stage movement. Monitor the distance

between the membrane and grid while bringing them together

with the use of the electron beam.

10. Bring the membrane and TEM grid to vertical alignment. Move

the stage in X and Y until the grid is directly beneath the

membrane (electron imaging).

Monitor the distance between the membrane and grid while

aligning them (ion imaging).

11. Iterate between the ion and electron imaging while moving the

stage until the membrane touches the grid.

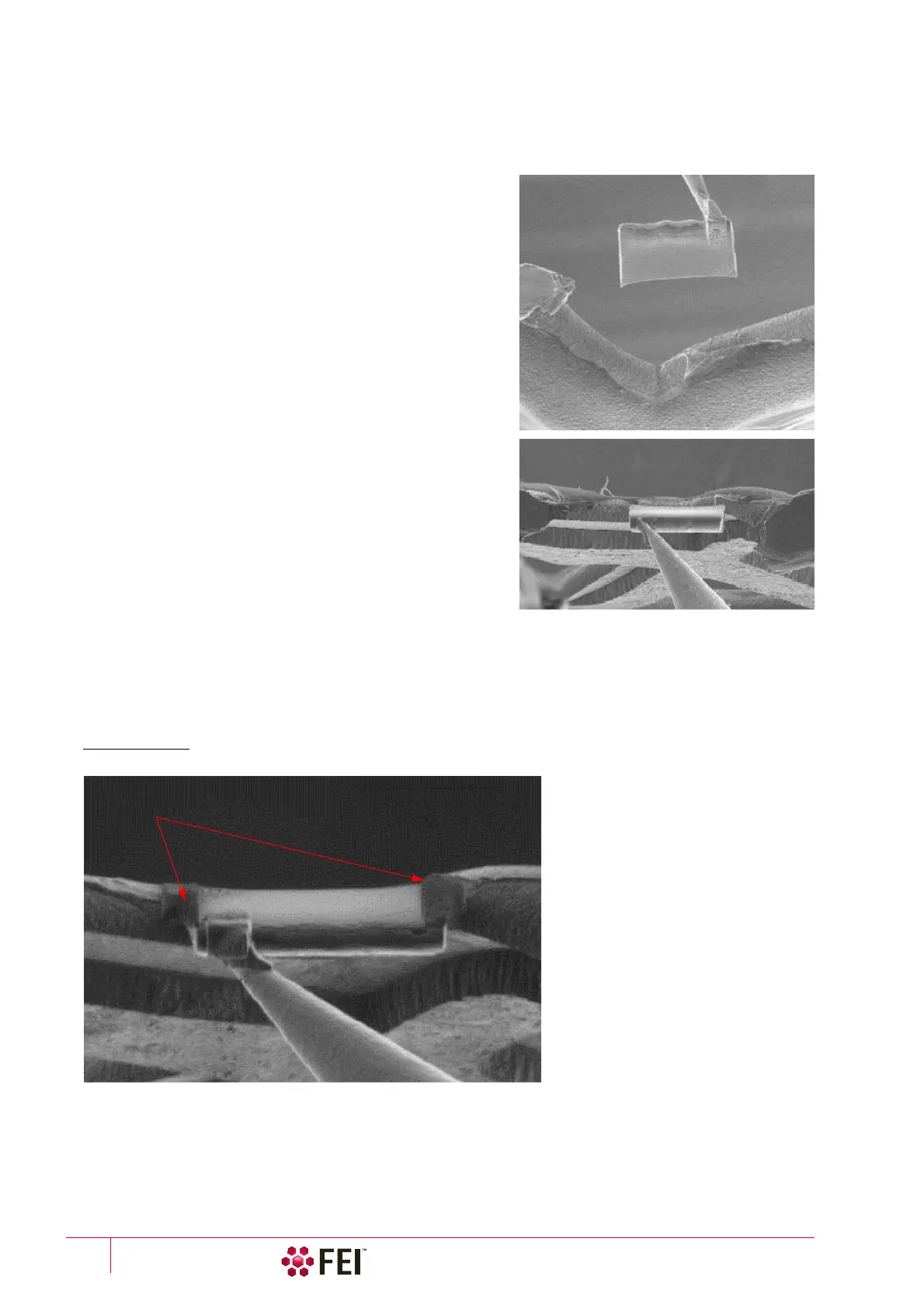

12. Deposit 5 × 4 × 1 µm metal boxes at the two contact corners.

Leave the GIS needle in place when welding is complete.

13. Select the 1 nA beam current and mill a small rectangle

(0.5

µm in Y) through the weld connecting the EasyLift tip and

the membrane to free the tip.

14. Lower the stage in Z direction.

15. Move the needle to the Park position.

16. Retract the EasyLift needle.

17. Retract the GIS needle.

FIGURE 7-7 Sample Reinforced with Tungsten Welds

Final Thinning

During final thinning, leave some material at the membrane base to provide structural support. Begin with a

relatively low beam current (1 nA or less) to avoid damaging the membrane.

Loading...

Loading...