G.2 Part. N. 8000 H1344 (10-2009)

ENGINE OVERHAULING

Cleaning of components

All component must be cleaned with petrol and dried with compressed air.

During this operation inammable vapours burst out and metal particles may be violently ejected. Consequently, it is recom-

mended to work in a room free from bare ames or sparks and that the operator wears goggles.

Assemblies

For a good and efcient engine operation, it is essential that all assemblies are within the tolerances prescribed. In fact, a “close”

assembly causes seizures as soon as the moving members heat up; while a “wide” assembly causes vibrations which in addition to

being noisy accelerate the wear of the moving components.

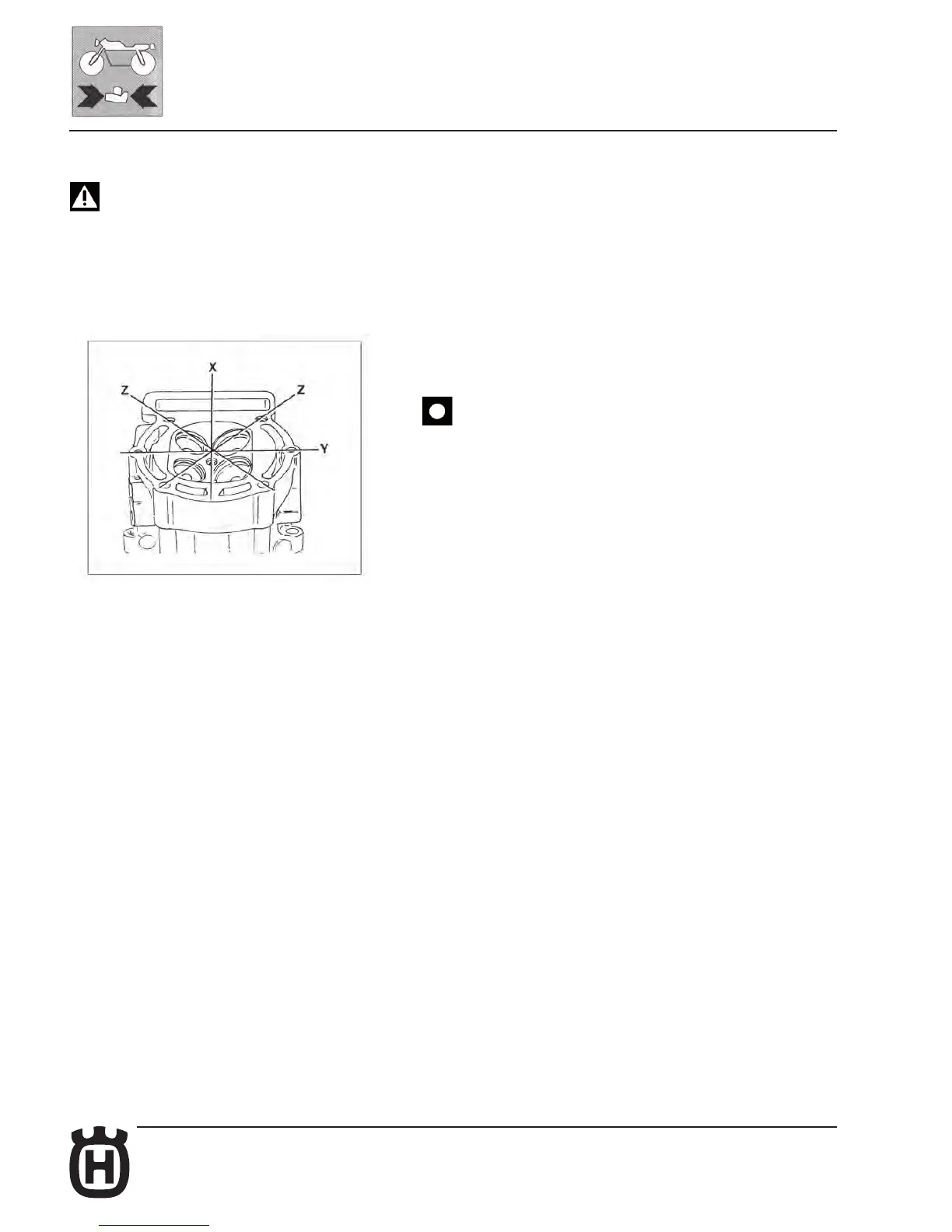

Cylinder head

Remove carbon deposits from the combustion chamber using a rounded

scraper.

Do not use a sharp tool to avoid valve seats and spark plug thread

damaging.

Check the machined surfaces of the cylinder head using a straight edge

and a feeler gauge taking readings at the points shown in the gure. If

the reading at any point is greater than the limit prescribed then regrind

the contact surface with the cylinder. Cylinder head distortion limit:

0.0019 in.

Loading...

Loading...