4. Operation

4.2 Operation in Positioner Mode

4-46

ME0342-4B

Caution

● The speed during pressing operation is set in Parameter No.34. Check [9.4 List of

Specifications of Connectable Actuators] for the pressing operation speed.

Do not set any value larger than the value in the list. If the speed set in the position table

is equal to or less than the pressing speed, the pressing is performed at the setup speed.

● The approach start position of pressing should be located at or before the pressing start

position (coordinate 100mm or less in the above example) If not, the moving direction

varies depending on the start position to be dangerous.

For example, pressing at coordinate larger than the pressing end position (larger than

150mm) is the tension operation in the direction from the current position to the pressing

end position. Note that pressing after positioning to the position of coordinate 100mm

does not take place.

● A pressing operation command from a coordinate above the pressing termination

position (150mm or more) should not be performed when the force sensor is used.

Attempting to do so should cause Alarm: 0A3 "Position Command Data Error".

● The work is pressed after the pressing is completed. The work may moves backward or

forward. If the actuator is moved backward before the approach position, alarm 0DC

“Pressing motion range over error” occurs to stop the actuator. In movement of the work

in the pressing direction, PEND is turned OFF if the load current becomes lower than the

current limit (pressing [%]). Miss-pressing occurs when the actuator moves by the

pressing moving distance set in “Positioning width”.

● Do not make control of changing to pressing on the way of normal positioning (before

PEND turning ON). Depending on the position at which start signal CSTR is turned ON, the

pressing is performed improperly. Then the PLC cannot manage the position of the

actuator.

● Pressing control cannot be performed with the rotary actuator. If the index mode is

selected for the rotary actuator of multi-rotation specification, pressing operation cannot

be set. The positioning complete signal PEND is turned ON when the actuator reaches

the positioning width.

●

If the

actuator

gets pressed to the work during the approach operation, error would be

issued.

Pressing start position

100mm

Pressing end position

100 + 50 = 150mm

Tension start position

100mm

Pressing end position

100 + 50 = 150mm

4.2 Operation in Positioner Mode

ME0342-4B 4-47

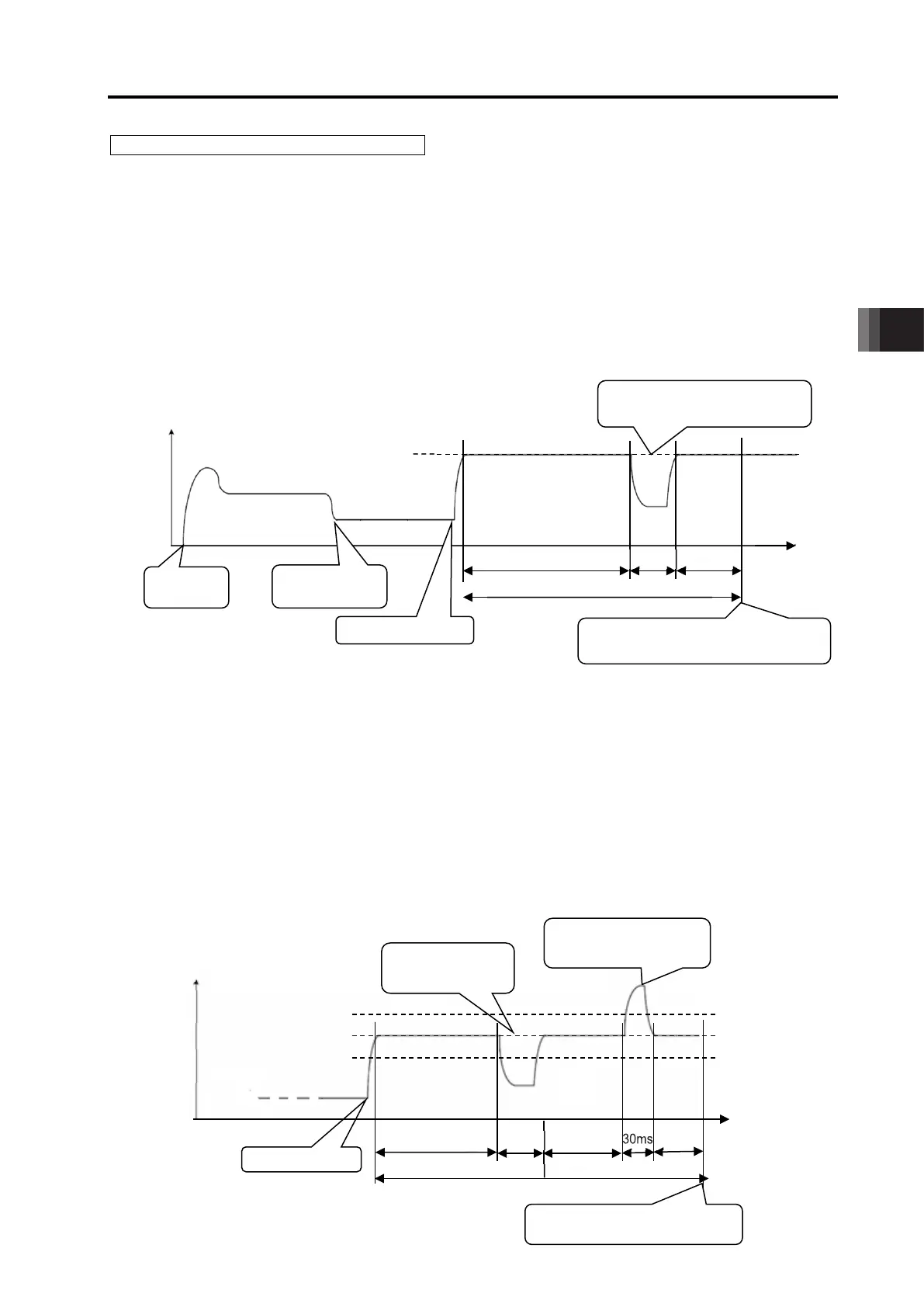

Judging completion of pressing operation

(1) For Standard (PIO Patterns 0 to 3)

The operation monitors the torque (current limit value) in percent [%] in “Pressing” of the

position table and turns pressing complete signal PEND ON when the load current satisfies the

condition shown below during pressing. PEND is turned ON at satisfaction of the condition if the

work is not stopped.

(Accumulated time in which current reaches pressing value [%])

– (accumulated time in which current is less than pressing value [%])

≥ 255 ms (Parameter No.6)

Note 1: Some of the gripper models should be set at 70ms in default.

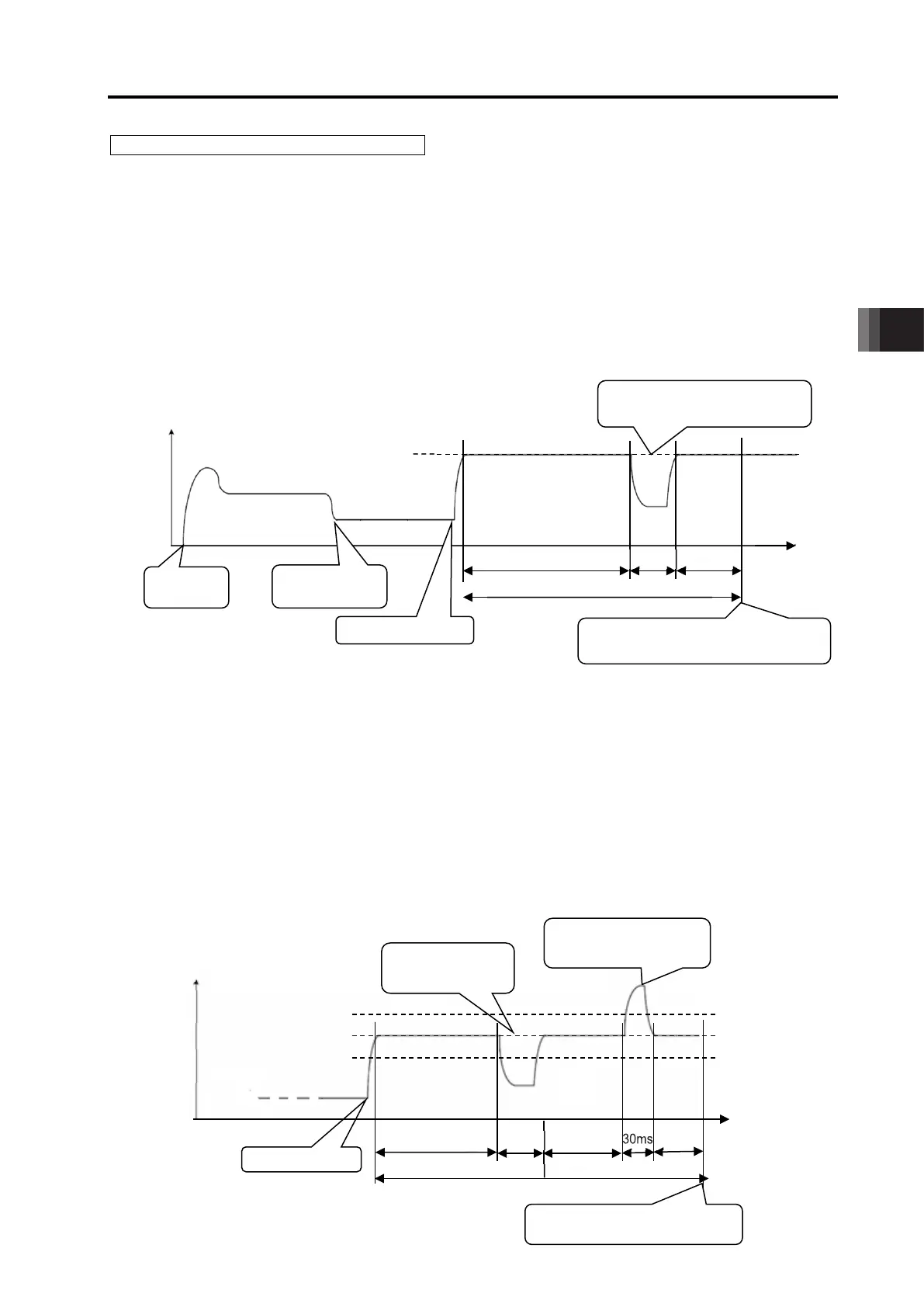

(2) For Force Sensor Used Pressing (PIO Pattern 6)

The pressing complete signal PEND should turn on when the pressing force during a pressing

operation satisfies the following condition against the percent [%] of the pressing force set in

"Pressing" in the position table. PEND should turn on once the condition is satisfied even if the

actuator is not stopped.

● Condition

(Accumulated Time of Pressing Force being in Range of Force Judgment Margin Positive and Negative)

≥ 255ms (Pattern No.6)

(150+135+50) - (50+30) ≥ 255ms

Pressing complete (PEND output)

due to workpiece being

Negative [%]

Force Judgment Margin

Positive [%]

Force

pressing force to

Pressing start

200ms + 75ms – 20ms ≥ 255ms

(Note 1)

Pressing complete (PEND output)

Decrease in current due to

movement of work

Loading...

Loading...