4. Operation

4.2 Operation in Positioner Mode

4-96

ME0342-4B

4.2.8 Preparation for Operation in Force Sensor Pressing

(Loadcell Calibration)

The force sensor pressing is a feature dedicated for PCON-CBP/CGBP.

With the performance of a loadcell for the feedback control of the pressing force during the

pressing operation in operation of the force sensor used pressing (PIO Patterns 6 and 7),

pressing operation with high precision should be available.

Before having the pressing operation of the force sensor used pressing, have the settings and

process described below established.

Caution

● For the force sensor used pressing, there is a need of an actuator applicable for the

dedicated loadcell and the force sensor used pressing.

● In the calibration, the value at the moment of the calibration should set as the datum

point (0 [N]). Therefore, it is necessary to consider that load of a fixture attached on the

loadcell should only be the load applied on the loadcell during the calibration.

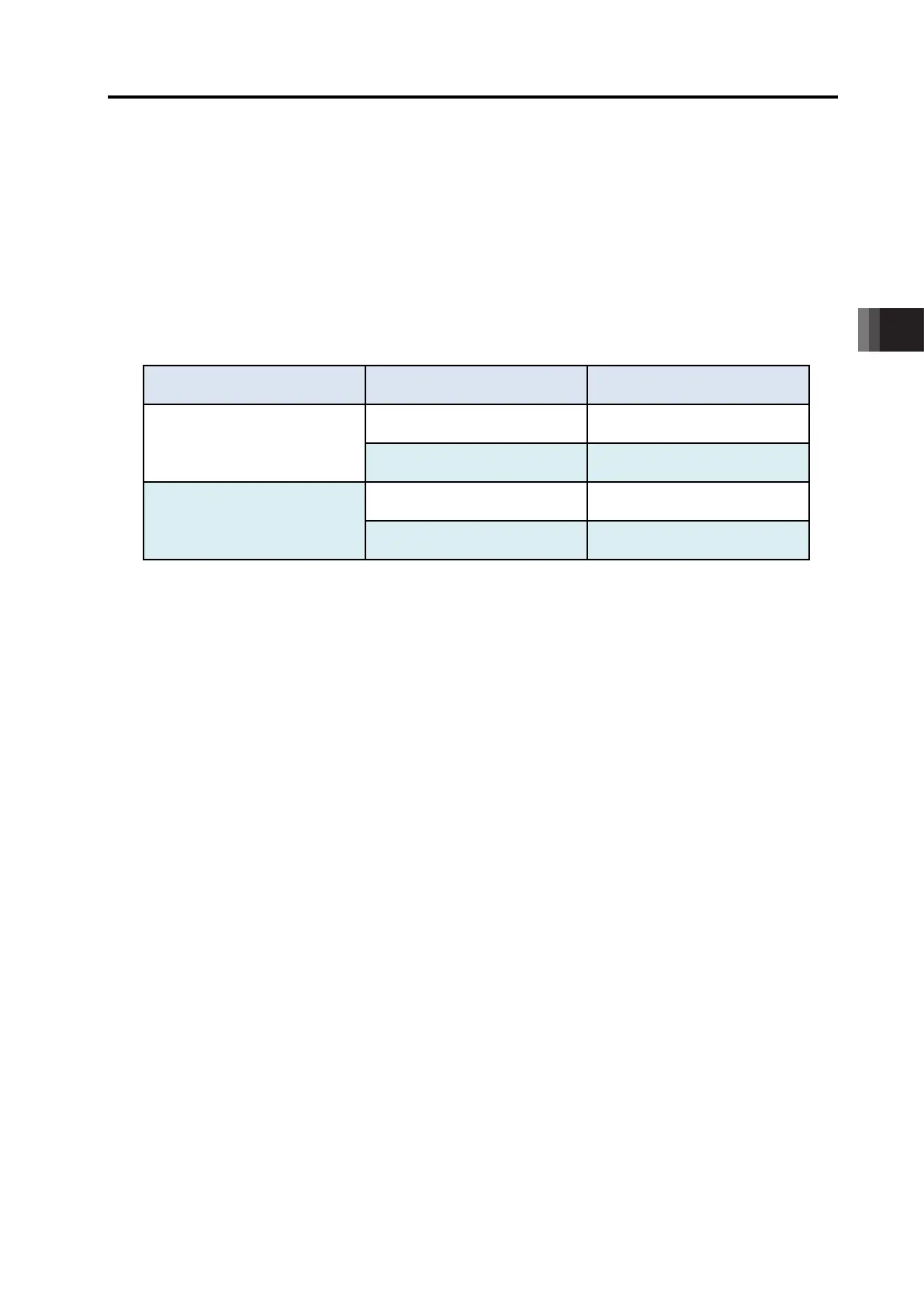

[1] Initial Setting

The pressing operation with the force sensor used pressing requires a use of a loadcell. It is

necessary to have the initial setting established before starting operation. Establish the settings as

shown in the thick-bordered boxes to the four parameters shown in the table below.

No. Name

Setting When

Using Force

Sensor Used

Pressing

Remark

92

Loadcell Use Select

[0: Not to Use / 1: To Use]

0: Loadcell Not to be Used

1: Loadcell to be Used

93

Pressing Control Select

[0: Current Limit / 1: Force Sensor]

1 1

0: Control with Current Limit

1: Control with Force Sensor

117

Automatic Loadcell Calibration at

Startup

[0: Not to Perform / 1: To Perform]

1

0: Loadcell Calibration Not to

be Performed

Automatically

1: Loadcell Calibration to be

Pressing Operation When Loadcell

Calibration Incomplete

[0: Prohibit / 1: Permit]

0 0

0: Pressing Operation When

Calibration Incomplete to

be Prohibited

1: Pressing Operation When

Calibration Incomplete to

4.2 Operation in Positioner Mode

ME0342-4B 4-97

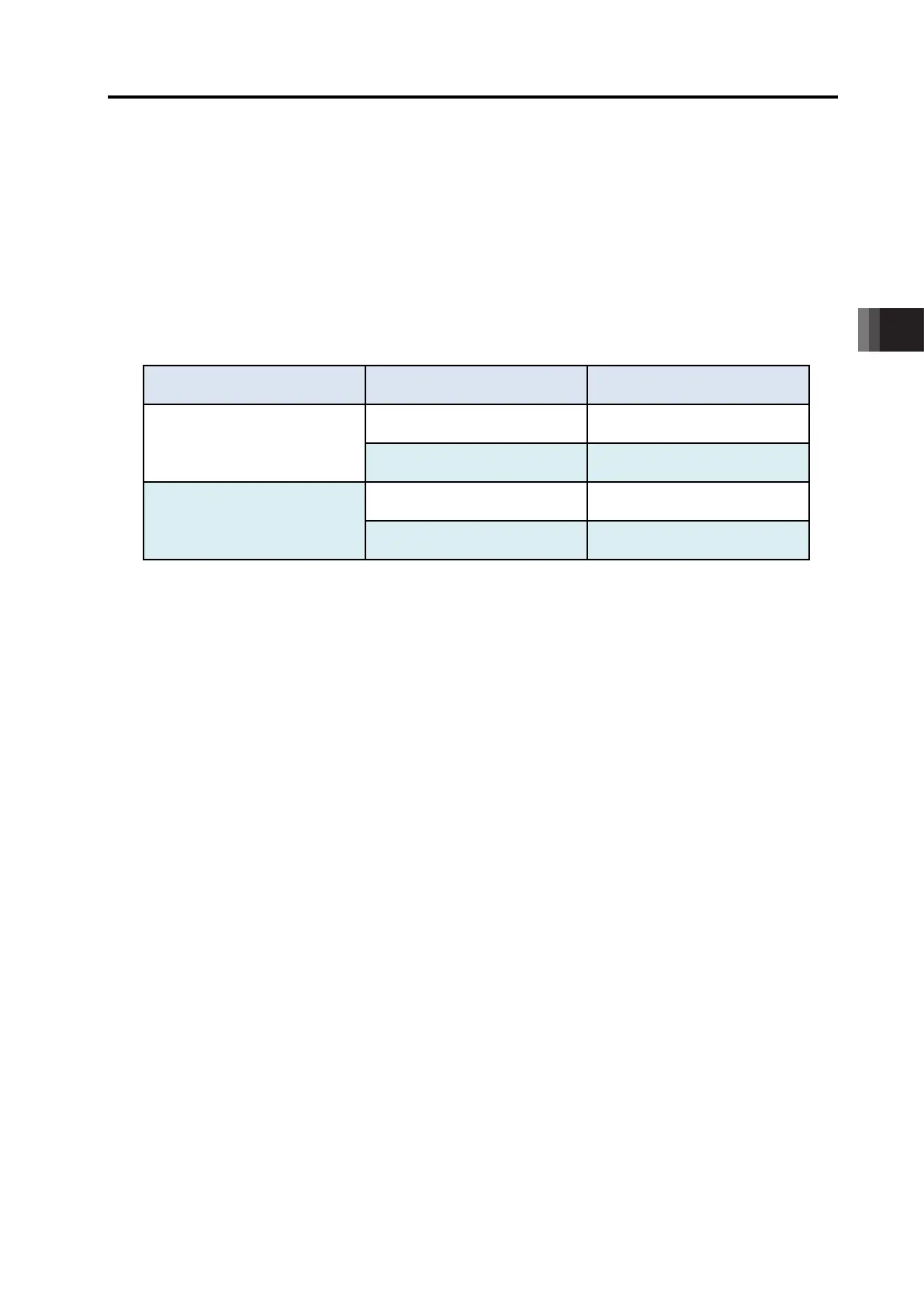

(1) Setting for Pressing Control with Loadcell

1) Select "1: Loadcell to be Used" in Parameter No. 92 "Loadcell Use Select". Set "0" and the

loadcell would not activate.

2) Select "1: Pressing Operation with Force Sensor Used Pressing" in Parameter No. 93

"Pressing Control Select". Set "0" and the pressing operation with the current limit should

activate.

[Settings in Parameter No. 92 and 93 and Pressing Control]

Parameter No.92

Loadcell Use Select

Parameter No.93

Pressing Control Select

Pressing Control

1: Loadcell to be Used

1: Control with Force Sensor

Pressing Operation with

Force Sensor Used Pressing

0: Control with Current Limit

Pressing Operation with

Current Limit

0: Loadcell Not to be Used

1: Control with Force Sensor

Alarm 0A1

Parameter Error

0: Control with Current Limit

Pressing Operation with

Current Limit

(2) Setup for Execution of Loadcell Calibration

The setting whether to perform calibration and also for a protection from pressing operation

started without calibration being performed.

1) In order to have accurate measurement, it is necessary to have calibration of the loadcell

in an appropriate period of frequency. Set "1" in Parameter No. 117 "Automatic Calibration

at Startup" in order to have calibration automatically and "0" to have it by manual.

When it is set to automatic, calibration should be performed once when the controller

power supply gets turned on, the software reset gets conducted from a teaching tool or at

a startup. At this moment, the duration for calibration should take 10ms. There is no need

of an actuator operation.

2) In Parameter No. 118 "Pressing Operation when Loadcell Calibration Incomplete", a

protection setting not to have a pressing operation without having calibration performed

should be established. Set "0" in it. Executing a pressing operation without having a

calibration after the power gets turned on should cause Alarm 0E1 "Calibration Error".

Set "1" in it and a pressing operation without a calibration performed should be available.

Loading...

Loading...