6. Parameter

6.1 Parameter

6-9

ME0342-4B

[2] Soft Limit + Side, Soft Limit - Side (Parameter No. 3, No. 4)

No. Name Unit Input range

Default initial value setting

3 Soft limit + side

mm

(deg)

-9,999.99 to 9,999.99 Actual stroke on + side

4 Soft limit - side

mm

(deg)

-9,999.99 to 9,999.99 Actual stroke on - side

0.3 mm (deg) is added to the outside of the effective actuator stroke for the default setting.

Change as required to prevent collision when there are obstacles, or when used slightly above

effective stroke within the movable range.

The minimum setting unit is 0.01mm.

Caution

● At this time, take extra care not to set incorrect values as this will lead to a collision with

the mechanical end.

● If changing, set a value extended by 0.3mm to the outside of the effective stroke.

Example) To set the effective stroke between 0.0mm and 80.0mm

Parameter No.3 (+ side) 80.3

Parameter No.4 (- side) -0.3

The movable range of jog or inching after home return will be 0.2mm inside the set value.

Alarm 0D9 "Software limit over error" occurs when the set value exceeds the value set in

parameter No. 88 "Soft limit margin" (default setting = 0). If parameter No. 88 is not set, the

value set for this parameter will become a detection value of the alarm 09D "Software limit over

error."

Approx. 0.3mm

0.2mm

Effective stroke

Software limit to set for the parameter

Approx. 0.3mm

0.2mm

80.0

Jog/inching movable range after home return

6.1 Parameter

ME0342-4B 6-10

[3] Homing Direction (Parameter No.5)

No. Name Unit Input range

Default initial value setting

5 Homing direction -

0: Reverse,

1: Forward

In accordance with actuator

Unless there is a request of Home Reversed Type (option), the home-return direction is on the

motor side for the line axis, counterclockwise side for the rotary axis and outer (open) side for the

gripper. Refer to [Actuator Coordinate System].

If it becomes necessary to reverse the home direction after the actuator is installed on the

machine, change the setting.

Caution

● Homing direction cannot be changed with some models.

● If it becomes necessary to reverse the homing direction after assembly to equipment,

check the model of the applicable actuator to ensure that the homing direction is

changeable.

● For models with which change is not possible, the actuator must be replaced.

Contact IAI if anything is unclear.

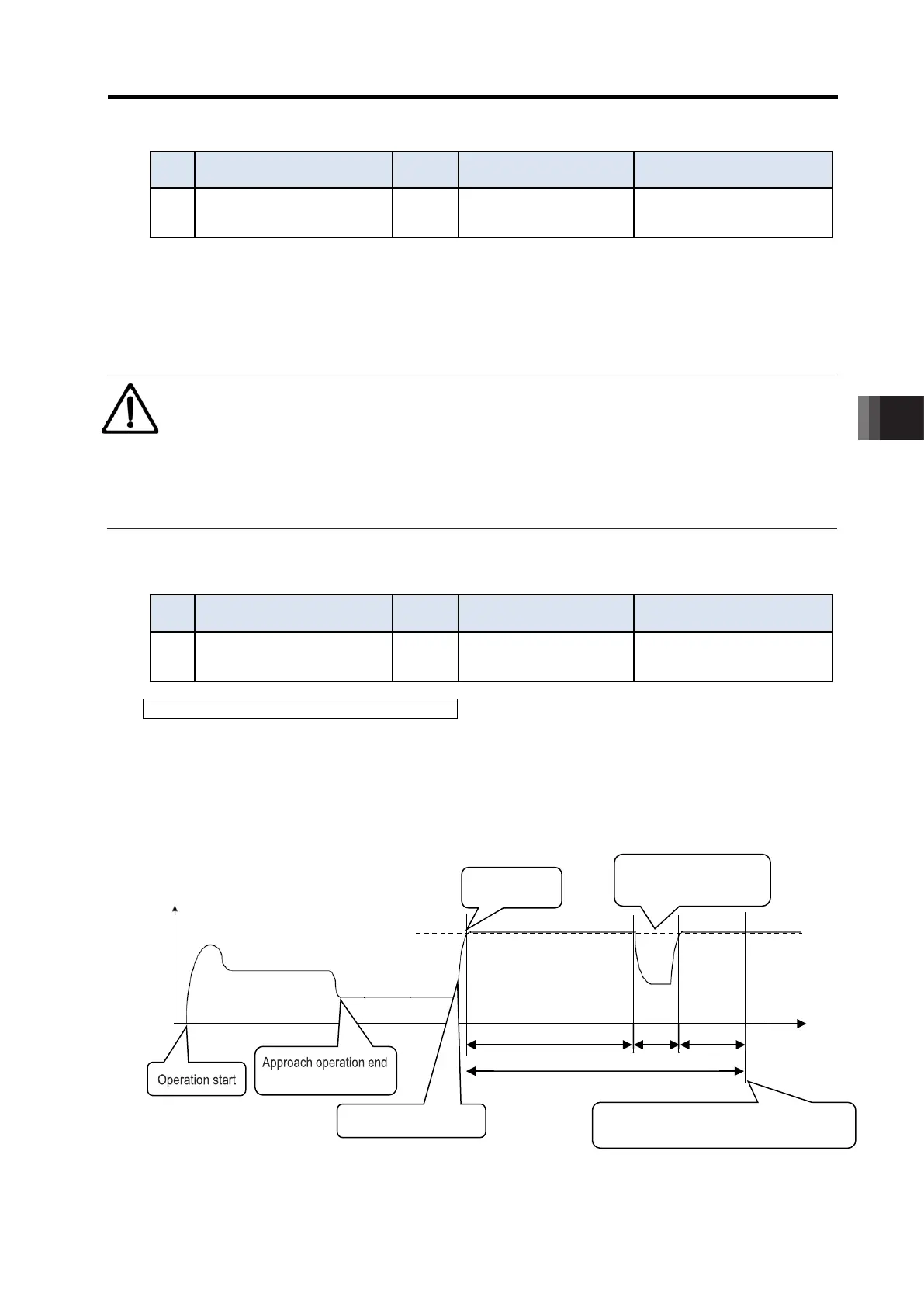

[4] Pushing Stop Recognition Time (Parameter No. 6)

No. Name Unit Input range

Default initial value setting

6

Pushing stop recognition

time

ms 0 to 9,999

In accordance with actuator

Judging completion of pressing operation

A parameter to set completion judgment time of push-motion operation (PIO pattern 0 to 3).

The torque (current limit value) set in percent [%] in "Pushing" in the position table is monitored,

and the pushing complete signal PEND turns ON when the load current reaches the following

conditions during push-motion operation. PEND signal turns ON when the conditions are

satisfied even if the workpiece is not stopped.

(Accumulated time in which current has reached push value [%]) - (accumulated time in which current is less than push value [%])

≥255ms (Parameter No.6)

Note 1 : The default is set to 70ms for some models of the gripper type.

Time

Contacting workpiece

Decrease in current

due to workpiece travel

200ms + 75ms - 20ms ≥ 255ms

(Note 1)

Push complete (PEND output)

Loading...

Loading...