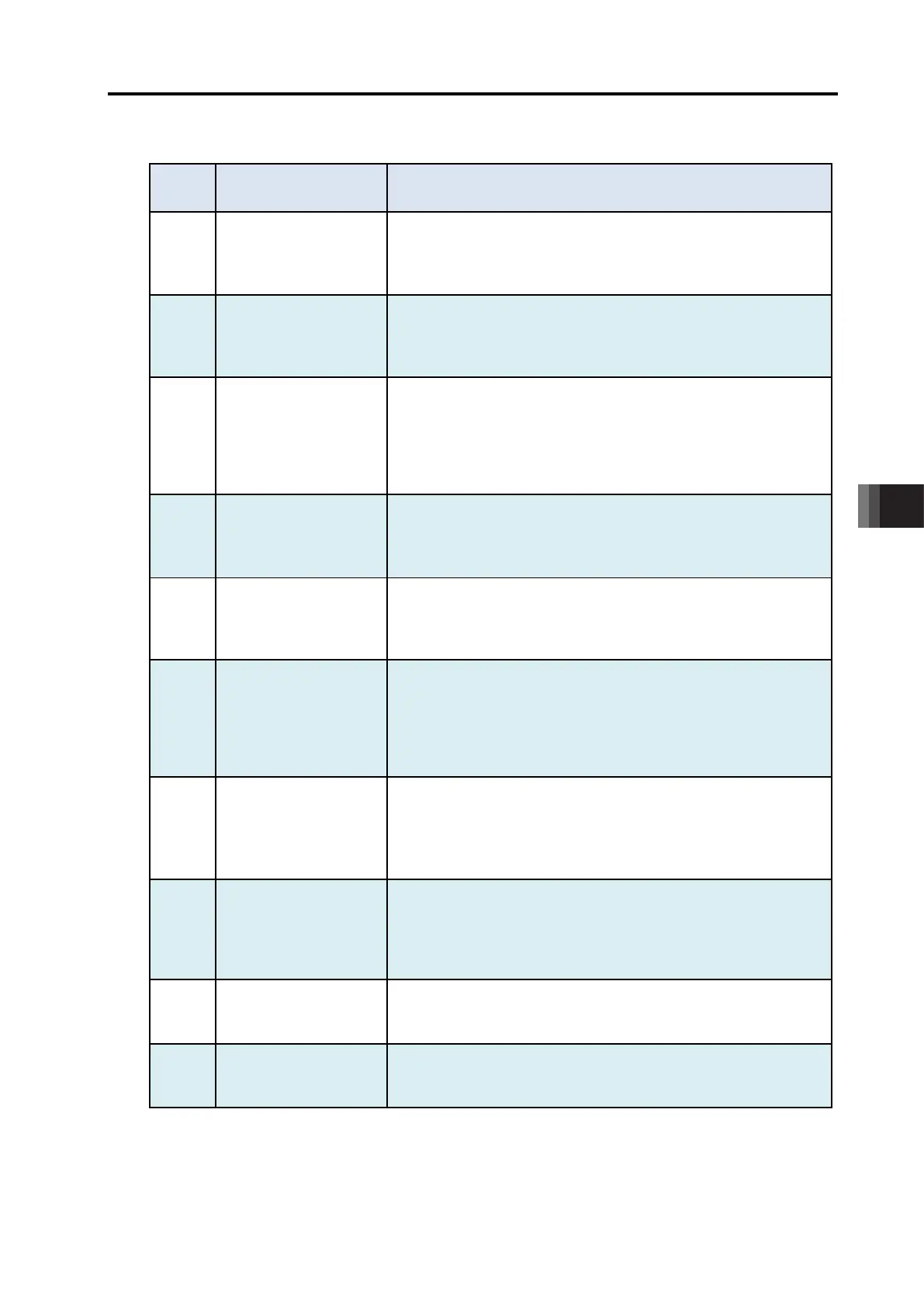

8. Troubleshooting

8.3 About Alarms

8-15 ME0342-4B

Cause : Fan total running time has exceeded the replacement

guidelines.

Countermeasure : The alarm can be canceled without replacing the

fan unit, but we recommend replacing the fan unit

before it breaks down as an aspect of preventive

maintenance.

Refer to [7.4.2 How to replace Fan unit] for how to

Travel count target value

exceeded

Cause : The total travel count set by Parameter No.147 "Total Travel

Count Target Value" has been exceeded.

04F Travel distance target

Cause : The total travel distance set by Parameter No.148 "Total

Travel Distance Target Value" has been exceeded.

Cause : Valid data was not detected even after 5s has passed since

the start (header) of Modbus communication was detected.

Delimiter error packet

receive

Cause : Valid data cannot be detected with Modbus communication,

or abnormal data was received.

069 Detection of realtime

clock oscillation stop

Cause : The calendar function is stopped and the current time data is

lost.

Countermeasure : Set the time again.

Refer to the [Instruction Manual of RC PC

software.]

Note This error is not registered in the alarm list.

Cause : The calendar function is not working properly because of

noise or malfunction of consisting parts.

Countermeasure : 1) Take proper measures against noise.

2) When the calendar function is not used, set

parameter No.111 “Calendar Function Use

Select” to “0”.

3) If the operation is not improved in use of the

calendar function in spite of measures against

noise, replace the controller.

Cause : The maintenance information (total movement count, total

operated distance) is lost.

Countermeasure : Consider to replace the controller when the

maintenance information is used.

Refer to [teaching tool instruction manual]

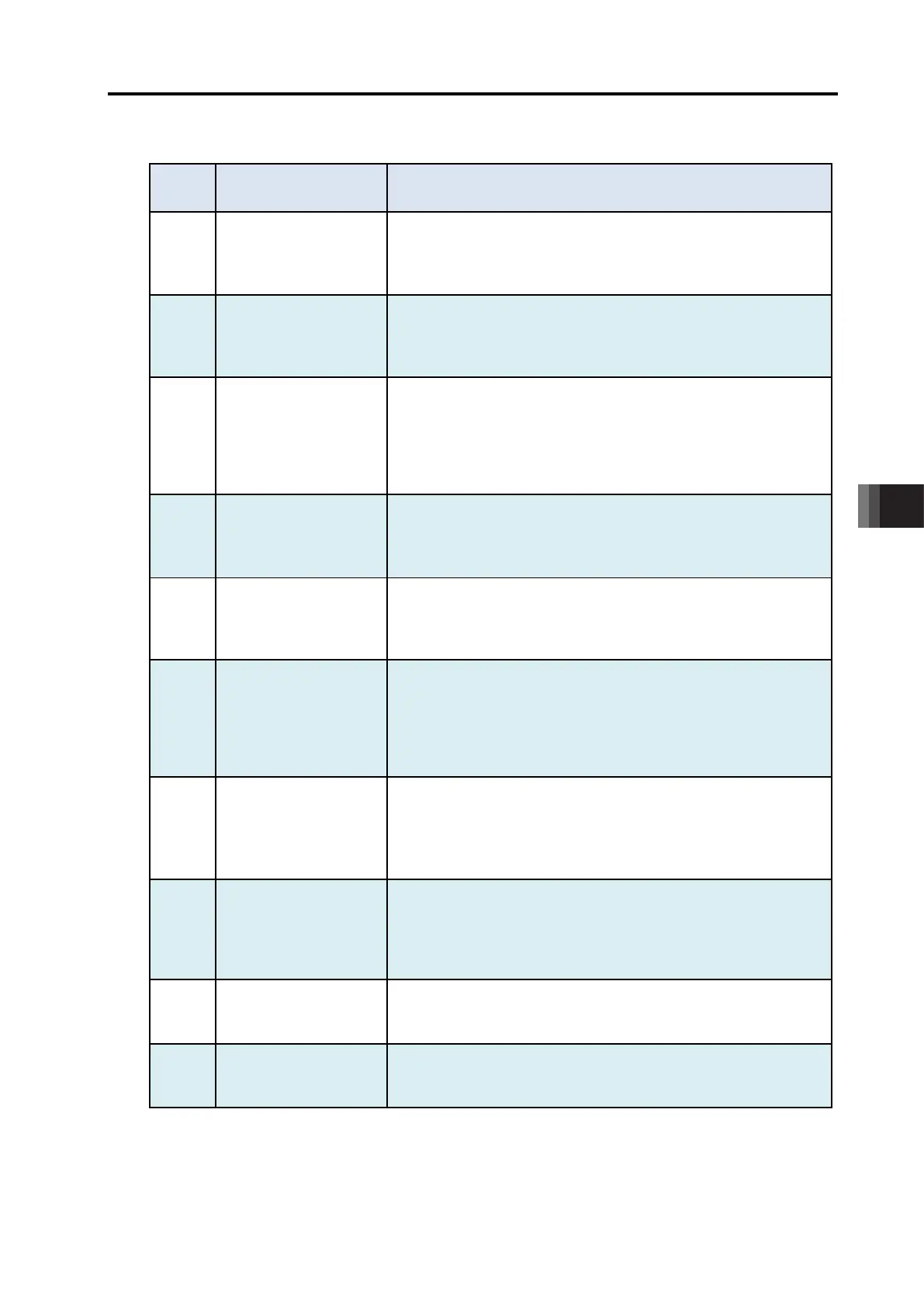

8.3 About Alarms

ME0342-4B 8-16

[2] Operation cancel level

Alarm Name Alarm Name

080 Travel command during

servo OFF

Cause : Travel command was issued in servo OFF status.

Countermeasure : Execute travel commands after confirming servo

ON status (servo ON signal SV or positioning

complete signal PEND is ON).

in homing incomplete

status

Cause : Position travel command was input with home return status

incomplete.

Countermeasure : Execute travel commands after confirming the

home return complete signal HEND is ON.

homing incomplete

Cause : Absolute position direct numerical command was issued in

incomplete home return status.

(Direct numerical command via field network, etc.)

Countermeasure : Perform home return motion, confirm the home

return complete signal HEND, and then perform

direct numerical command.

084 Travel command during

home return execution

Cause : Travel command was issued during home return execution.

Countermeasure : Perform home return motion, confirm the home

return complete signal HEND, and then perform

Position No. error during

travel

Cause : Position number that does not exist (invalid) in positioner

mode was specified.

Countermeasure : Check the position table again and specify a valid

when pulse train input

enabled

Cause : An actuator operation command was issued from the serial

communication while the pulse train input enabled or the

motion command is enabled.

Countermeasure : Do not attempt to issue any actuator operation

command from the serial communication in the

pulse train mode and the motion mode.

during loadcell calibration.

Cause : A movement command was issued during loadcell calibration.

Countermeasure : Confirm on the calibration complete (CEND) signal

that the loadcell calibration has finished, turn CLBR

Signal off and then have a movement command

088 Force Sensor Pressing

Command While Loadcell

Invalid

Cause : A pressing command by the force control was attempted with

the loadcell disabled.

Countermeasure : Reboot the controller, wait till the loadcell gets

activated, and then conduct a pressing command

in servo ON status

Cause : A software reset command was issued in servo ON status.

Countermeasure : Check that servo is in OFF status (SV signal is

OFF status) and issue a software reset command.

Position No. error during

teaching

Cause : A position number out of the range was indicated in the current

position writing command.

Countermeasure : Select the position number from 63 or smaller.

Loading...

Loading...