3.

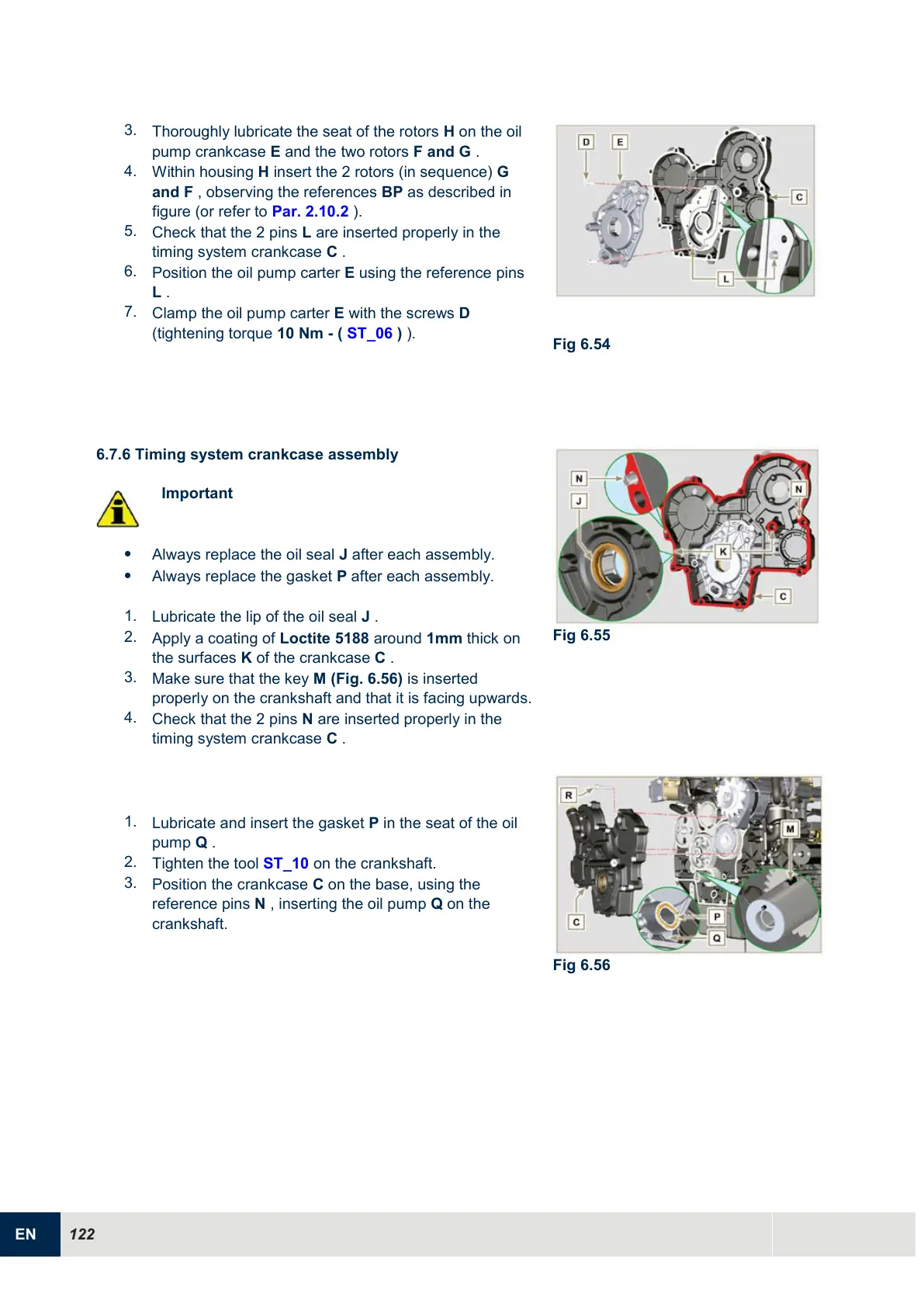

Thoroughly lubricate the seat of the rotors H on the oil

pump crankcase E and the two rotors F and G .

4.

Within housing H insert the 2 rotors (in sequence) G

and F , observing the references BP as described in

figure (or refer to Par. 2.10.2 ).

5.

Check that the 2 pins L are inserted properly in the

timing system crankcase C .

6.

Position the oil pump carter E using the reference pins

L .

7.

Clamp the oil pump carter E with the screws D

(tightening torque 10 Nm - ( ST_06 ) ).

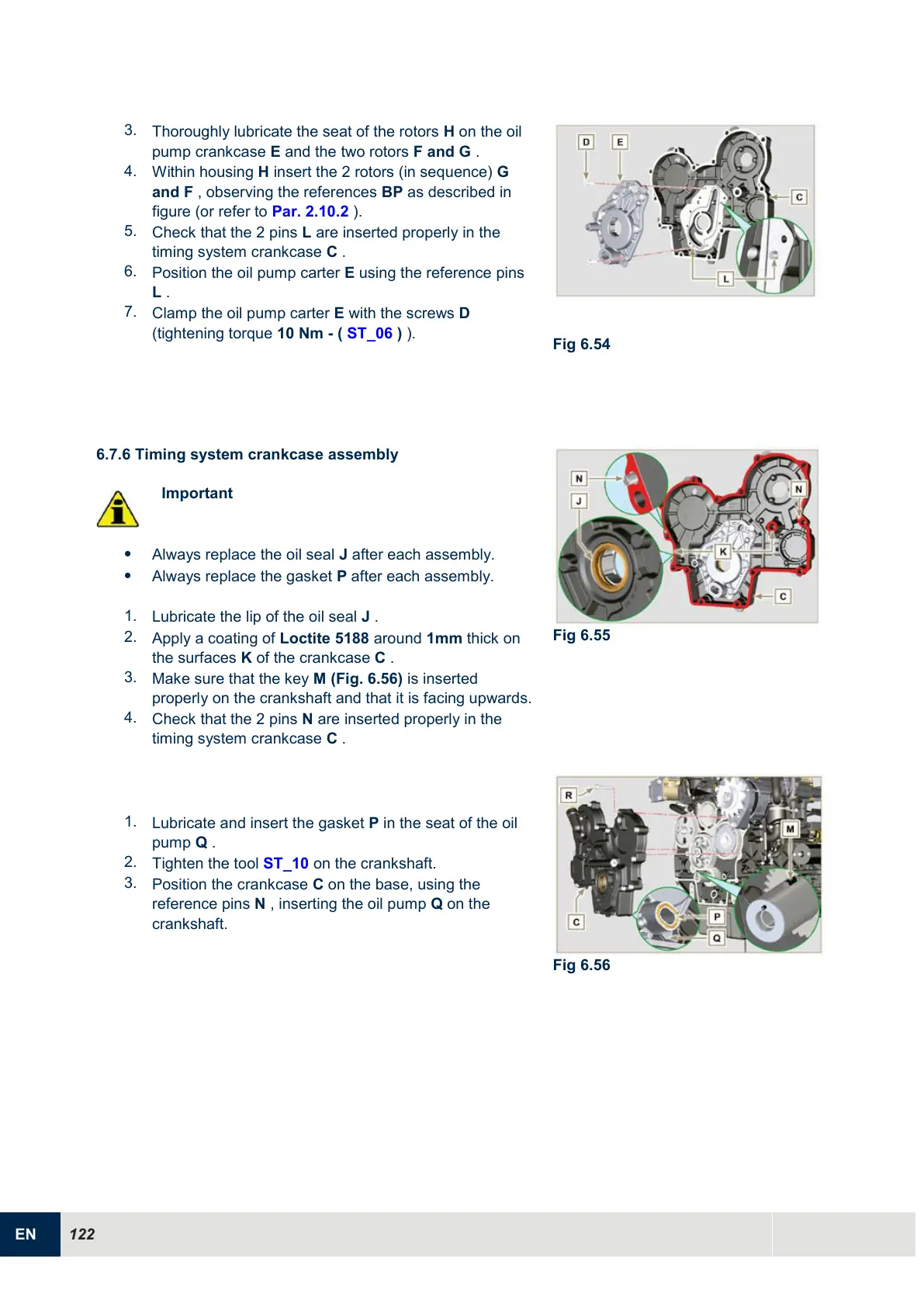

6.7.6 Timing system crankcase assembly

Important

Always replace the oil seal J after each assembly.

Always replace the gasket P after each assembly.

1.

Lubricate the lip of the oil seal J .

2.

Apply a coating of Loctite 5188 around 1mm thick on

the surfaces K of the crankcase C .

3.

Make sure that the key M (Fig. 6.56) is inserted

properly on the crankshaft and that it is facing upwards.

4.

Check that the 2 pins N are inserted properly in the

timing system crankcase C .

1.

Lubricate and insert the gasket P in the seat of the oil

pump Q .

2.

Tighten the tool ST_10 on the crankshaft.

3.

Position the crankcase C on the base, using the

reference pins N , inserting the oil pump Q on the

crankshaft.

Loading...

Loading...