1.

Perform the operations described in Par.

8.5.4 .

2.

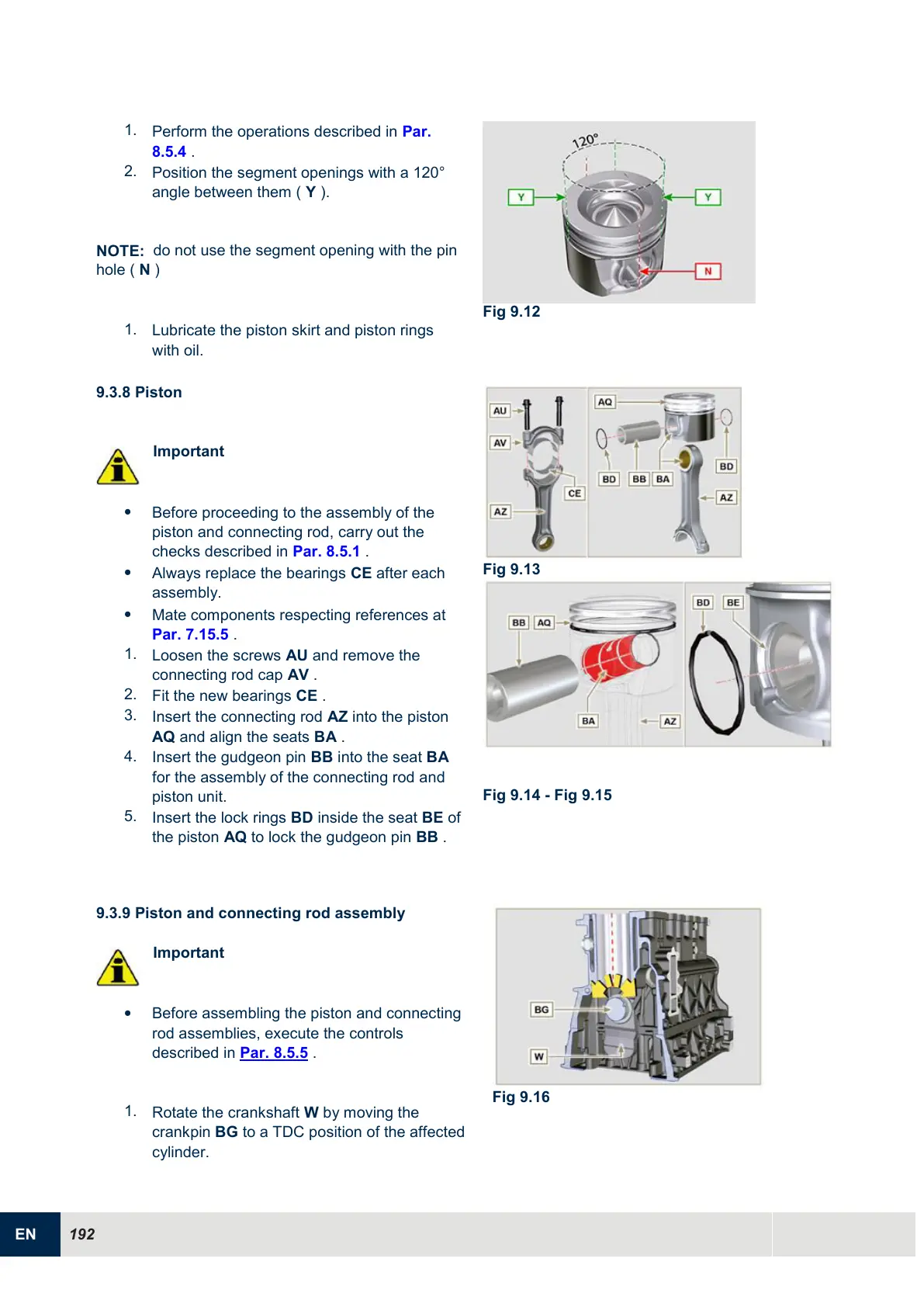

Position the segment openings with a 120°

angle between them ( Y ).

NOTE:

do not use the segment opening with the pin

hole (

N

)

1.

Lubricate the piston skirt and piston rings

with oil.

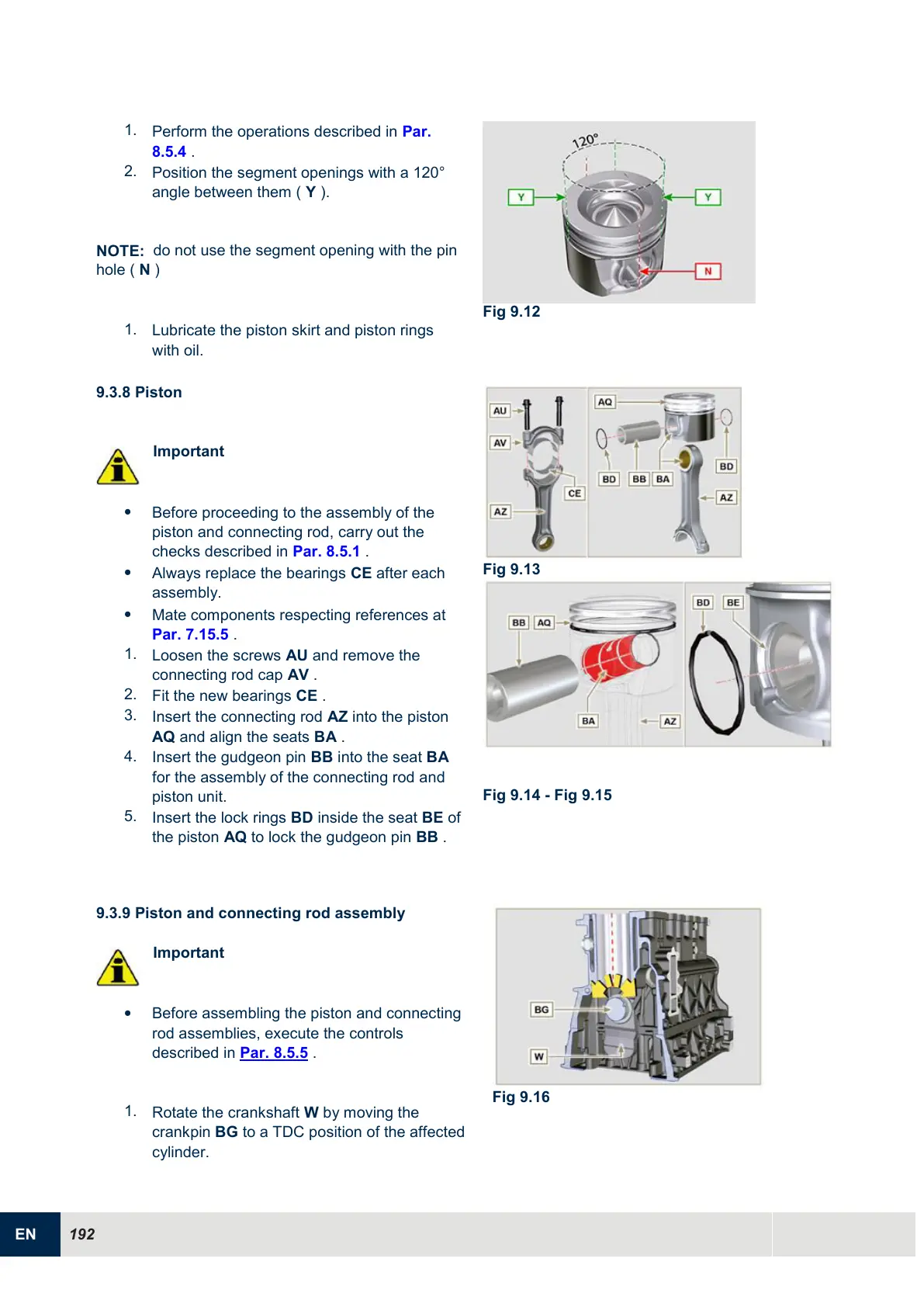

9.3.8 Piston

Important

Before proceeding to the assembly of the

piston and connecting rod, carry out the

checks described in Par. 8.5.1 .

Always replace the bearings CE after each

assembly.

Mate components respecting references at

Par. 7.15.5 .

1.

Loosen the screws AU and remove the

connecting rod cap AV .

2.

Fit the new bearings CE .

3.

Insert the connecting rod AZ into the piston

AQ and align the seats BA .

4.

Insert the gudgeon pin BB into the seat BA

for the assembly of the connecting rod and

piston unit.

5.

Insert the lock rings BD inside the seat BE of

the piston AQ to lock the gudgeon pin BB .

9.3.9 Piston and connecting rod assembly

Important

Before assembling the piston and connecting

rod assemblies, execute the controls

described in Par. 8.5.5 .

1.

Rotate the crankshaft W by moving the

crankpin BG to a TDC position of the affected

cylinder.

Loading...

Loading...