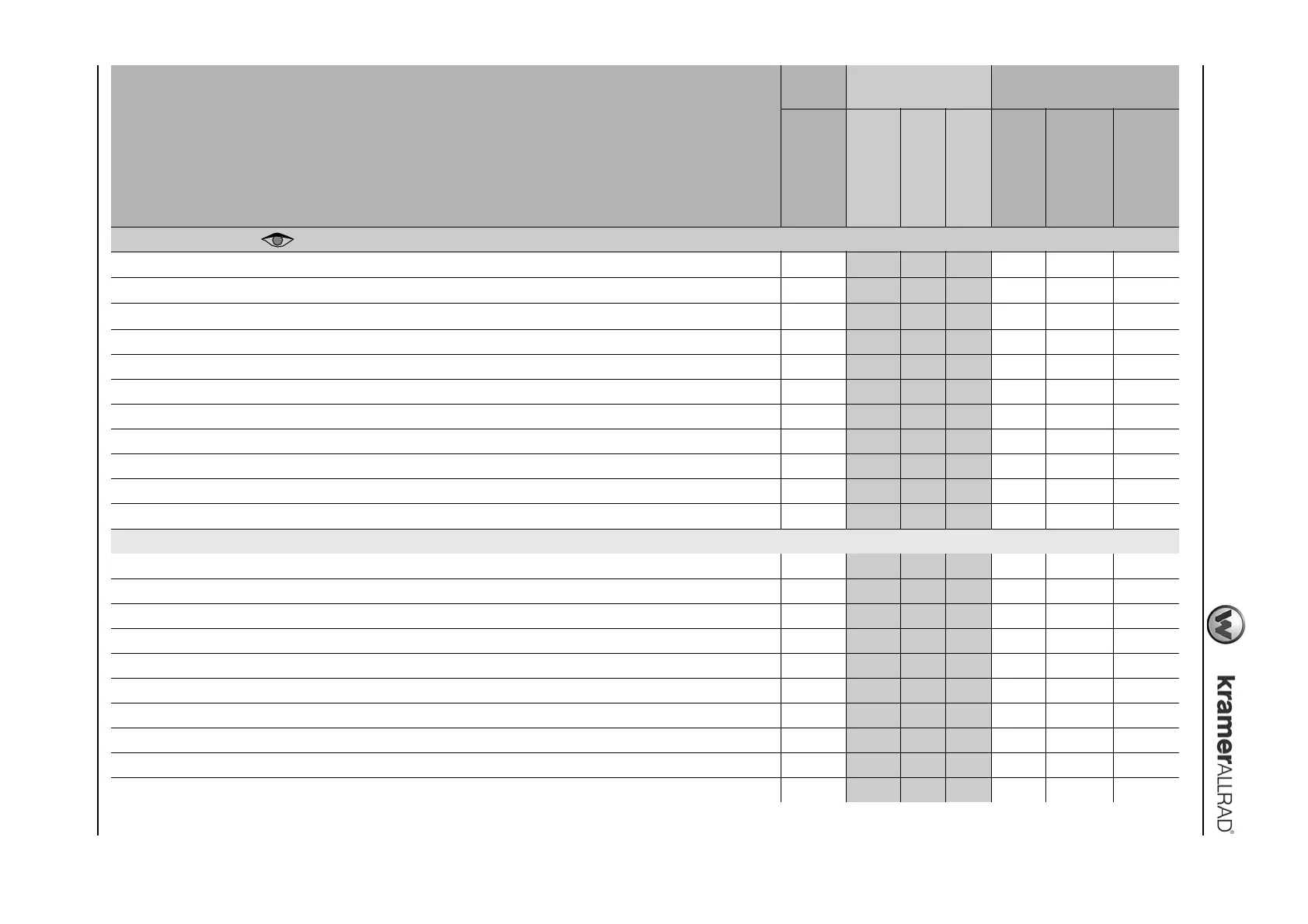

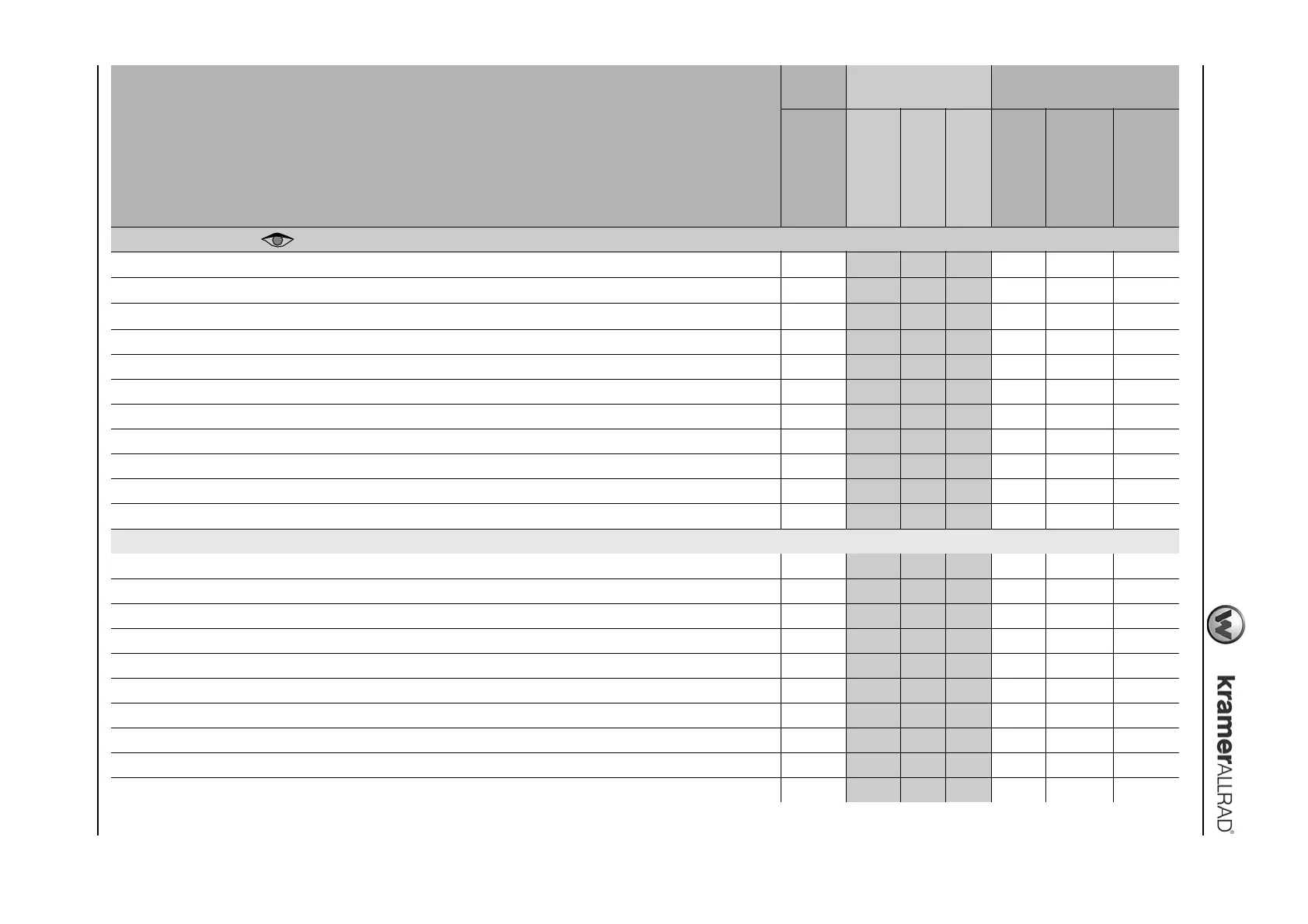

5-48 BA 35101/02/03 EN – Edition 1.0 * 35201_02b540.fm

Maintenance

Other inspection work ( ):

• When using biodegradable oil: drain the condensation water in the hydraulic oil tank

5

●●

• Clean dust valve on air filter housing

3

● ● ● ●● ● ●

• V-belt: check condition and pre-tension. Retighten or replace if necessary

10

● ● ● ●● ● ●

• Check the fuel/water separator. Drain water if necessary

● ●● ● ●

• Clean filter insert on fuel pump, replace if necessary

● ●● ● ●

• Check valve clearance (engine management). Set if necessary

●

• Battery: check charge condition

●●

• Heating: clean the fine-dust filter

● ●●

• Check and set service and parking brake pads. Replace if necessary

●● ●

• Tyre check (damage, air pressure, tread depth)

● ● ● ●● ● ●

• Aggressive media (option): check anticorrosion protection, renew if necessary

11

● ●● ●

Check screws and nuts or screw connections for tightness on the following assemblies/components. Retighten if necessary

• Engine and engine bearing

●● ●

• Steering system

●● ●

• Hydraulic system

●● ●

• Loader unit (pin locking)

●● ●

• Axle mounting, axle suspension

●● ●

• Counterweight (attachment)

●● ●

• Fastening screws of cardan shafts

●● ●

• Fastening screws of cab

●● ●

• Wheel nuts

● ●● ●

• Electrical system: check electric and earth connections, chafing on wiring harness, battery terminals

● ●● ●

5.24 Maintenance plan

Work description

For service and maintenance work on the attachment, please refer to the operation and maintenance manual of the

attachment manufacturer as well.

Work-

shop

Operator/driver Workshop

Delivery

inspection

Maintenance work

(once a day)

“A”

every 20 s/h

“A”

every 50 s/h

1st Inspection

1

at 100 s/h

“B”

every 500 s/h

2

2nd Inspection

“C”

every 1500 s/h

once a year

Loading...

Loading...