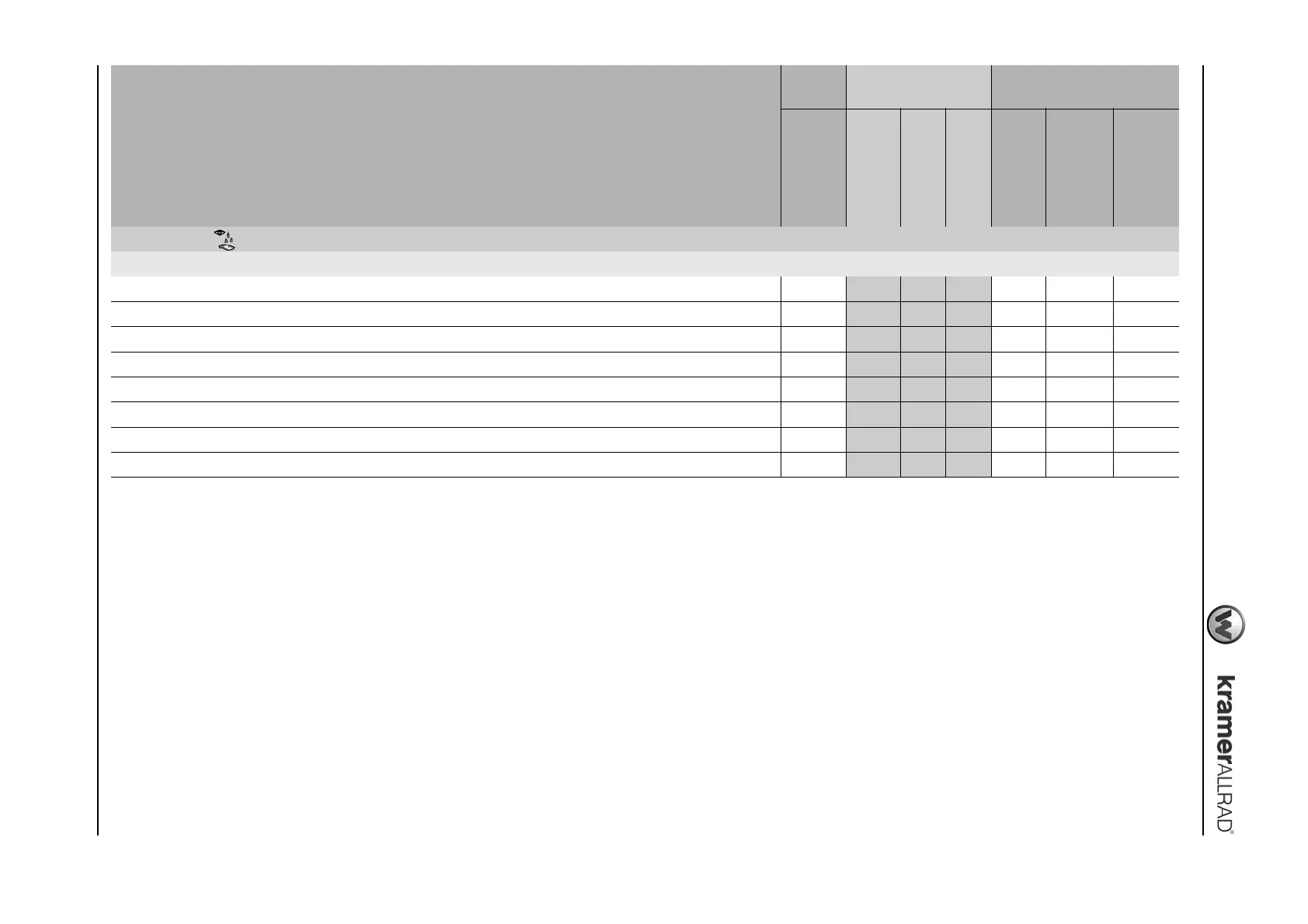

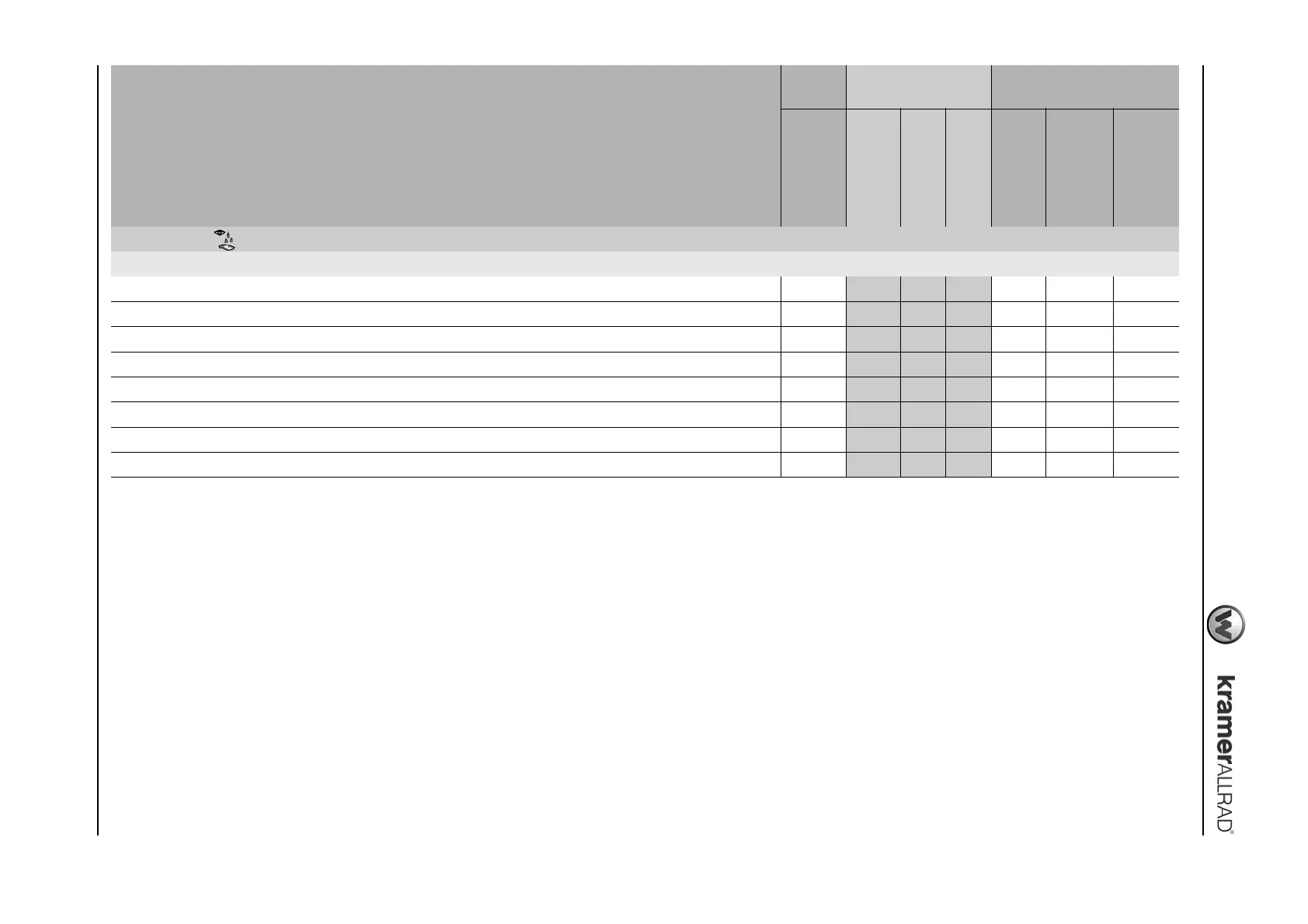

5-50 BA 35101/02/03 EN – Edition 1.0 * 35201_02b540.fm

Maintenance

Leakage check ( ):

Check for tightness, leaks and chafing: pipes, flexible lines and screw connections of the following assemblies and components. Rectify if necessary:

• Air intake line (air filter – engine)

● ● ● ●● ● ●

• Engine lubrication (engine – filter)

● ● ● ●● ● ●

• Fuel lines

13

● ● ● ●● ● ●

• Cooling system (engine – hydraulic oil)

● ● ● ●● ● ●

• Steering system (flexible lines and steering rams)

● ● ● ●● ● ●

• Hydraulic system/loader unit (flexible lines

14

and rams)

● ● ● ●● ● ●

• Brake system (flexible lines and cylinders)

● ● ● ●● ● ●

• Air conditioning system (option) – flexible lines, condenser, dehumidifier

● ● ● ●● ● ●

1. Work to be carried out once after the first 100 s/h. This work must be carried out by an authorised workshop for warranty claims to be acknowledged.

2. Work after the first 500 s/h (2nd Inspection) must be carried out by an authorised workshop for warranty claims to be acknowledged

3. Replace filter insert as indicated by the telltale on the air filter housing, however at least every 12 months or 1500 s/h.

4. When working in an acidic environment, replace the filter every 300 s/h!

5. When using biodegradable oil: drain the condensation water in the hydraulic oil tank every 500 s/h, in any case before the cold season.

6. Depending on operation and dust conditions, it may be necessary to replace the fine-dust filter more frequently

7. Replace the engine coolant every other year!

8. Replace every 2 years

9. Depending on operation and dust conditions, it can be necessary to clean the radiator more frequently

10. Replace the toothed belt every 3000 s/h or after 5 years at the latest (toothed belt must be replaced by authorised staff)

11. See maintenance instructions for aggressive media, order no. 1000108296

12. Lubricate attachment according to manufacturer's instructions!

13. Replace flexible fuel leak oil lines every 2 years

14. Replace flexible lines every 6 years (UVV, DIN 20066 part 5)

5.24 Maintenance plan

Work description

For service and maintenance work on the attachment, please refer to the operation and maintenance manual of the

attachment manufacturer as well.

Work-

shop

Operator/driver Workshop

Delivery

inspection

Maintenance work

(once a day)

“A”

every 20 s/h

“A”

every 50 s/h

1st Inspection

1

at 100 s/h

“B”

every 500 s/h

2

2nd Inspection

“C”

every 1500 s/h

once a year

Loading...

Loading...