181

2. 27 DPF STATIONARY REGENERATION METHOD

Take care of the following when carrying out DPF stationary regeneration.

• Due to the burning / removal process, the temperature of the exhaust gas rises to

about 600°C. Do not touch or come close to the DPF muffler, exhaust pipe or exhaust

gas. There is the danger of being burnt.

Also, if there are flammable objects placed in the surroundings, there is the danger of

a fire occurring.

• Since there is the danger of carbon monoxide poisoning, do not carry out DPF

regeneration in places with poor ventilation.

CAUTION

• The machine cannot be operated at all during DPF stationary regeneration.

Regeneration takes about 25 to 30 minutes to finish.

Make preparations, such as securing the work environment and refueling, before

starting regeneration.

• The engine speed rises when regeneration begins in order to raise the exhaust gas

temperature and is not a fault.

• If the machine is operated with the regeneration request lamp still lit on the monitor,

there is a risk of DPF damage and fire.

If the DPF regeneration request lamp is lit on the monitor,

make sure to carry out manual stationary regeneration.

1. Start the engine and put it in idling condition.

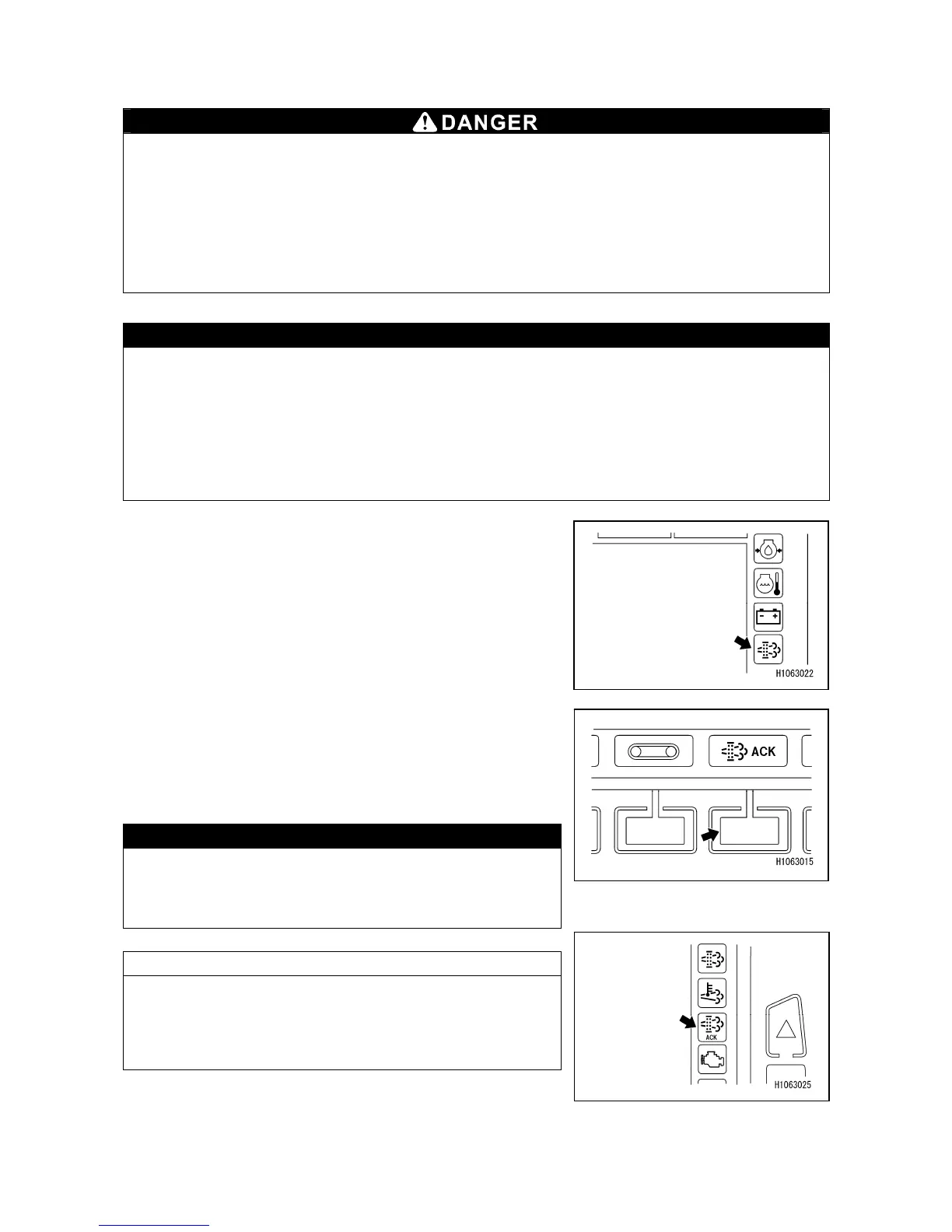

2. Start regeneration by pressing the DPF stationary

regeneration switch on the monitor.

As regeneration is started, the engine speed rises to

maximum and regeneration is carried out.

CAUTION

If DPF stationary regeneration needs to be stopped,

carry out the following operations.

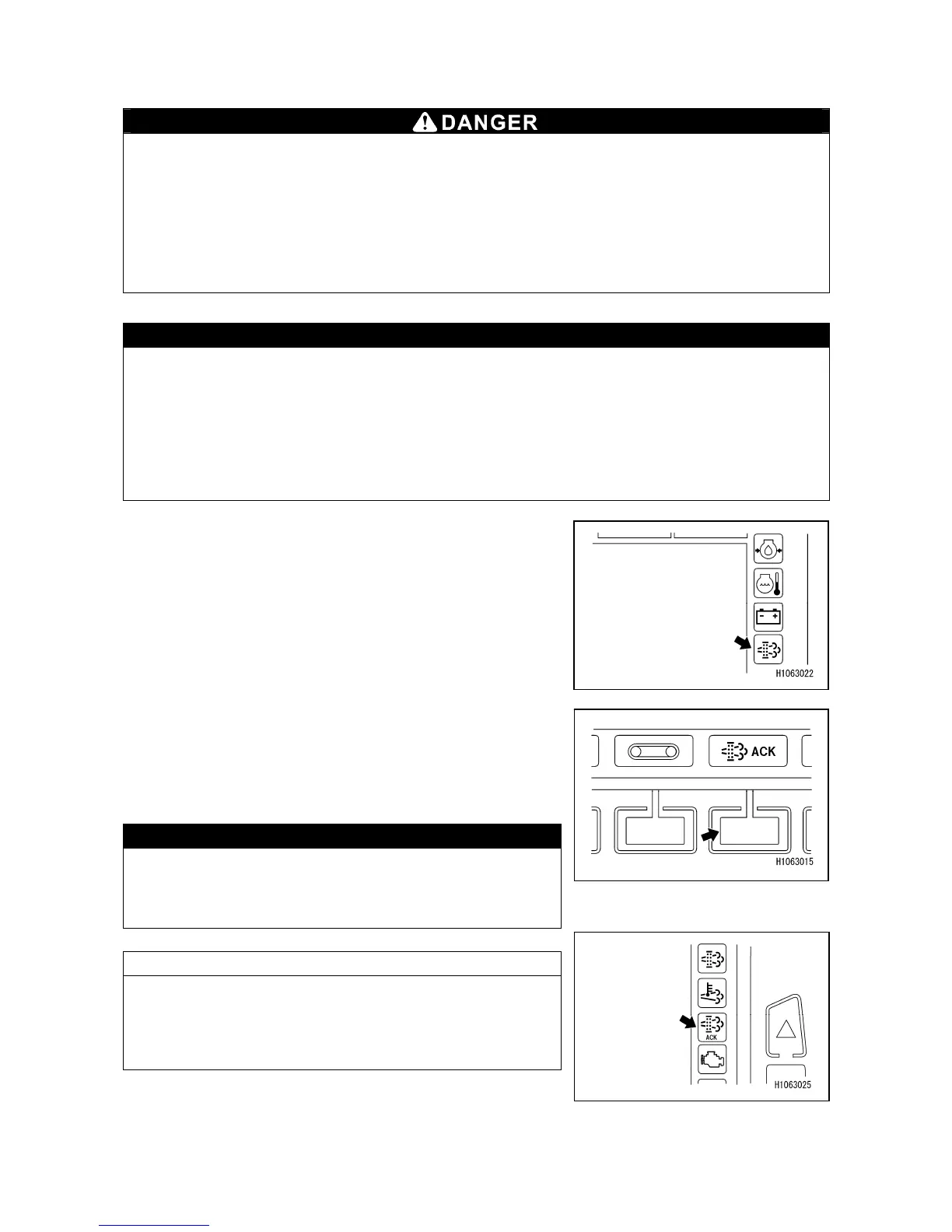

• Press the DPF stationary regeneration switch again.

• Turn the engine key OFF.

NOTES

During regeneration, the DPF regeneration lamp is lit on

the monitor.

As the exhaust gas is being cleaned, the smell of the

exhaust gas will differ from normal.

3. The engine speed returns to idling condition, the DPF

regeneration lamp goes out and regeneration ends.

Loading...

Loading...