303

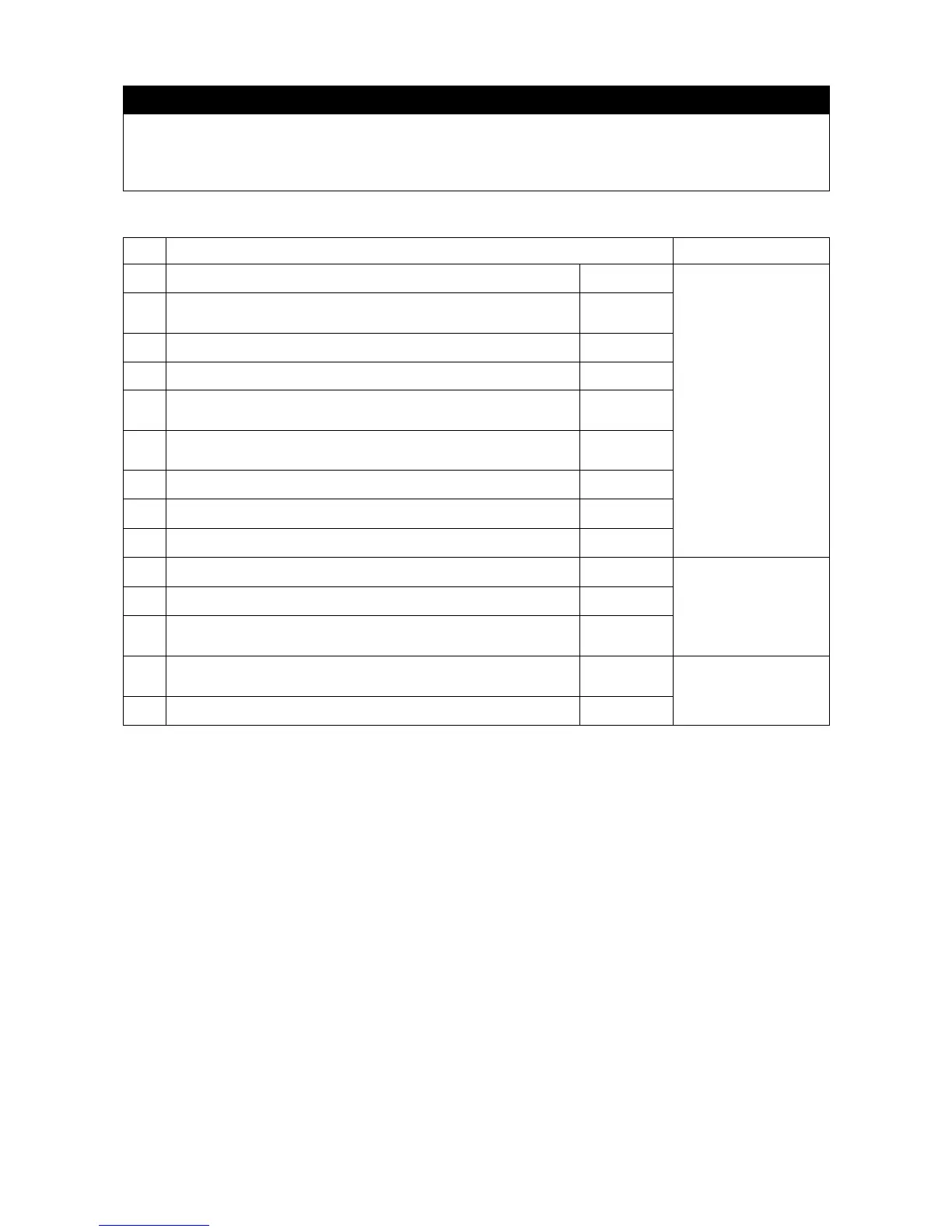

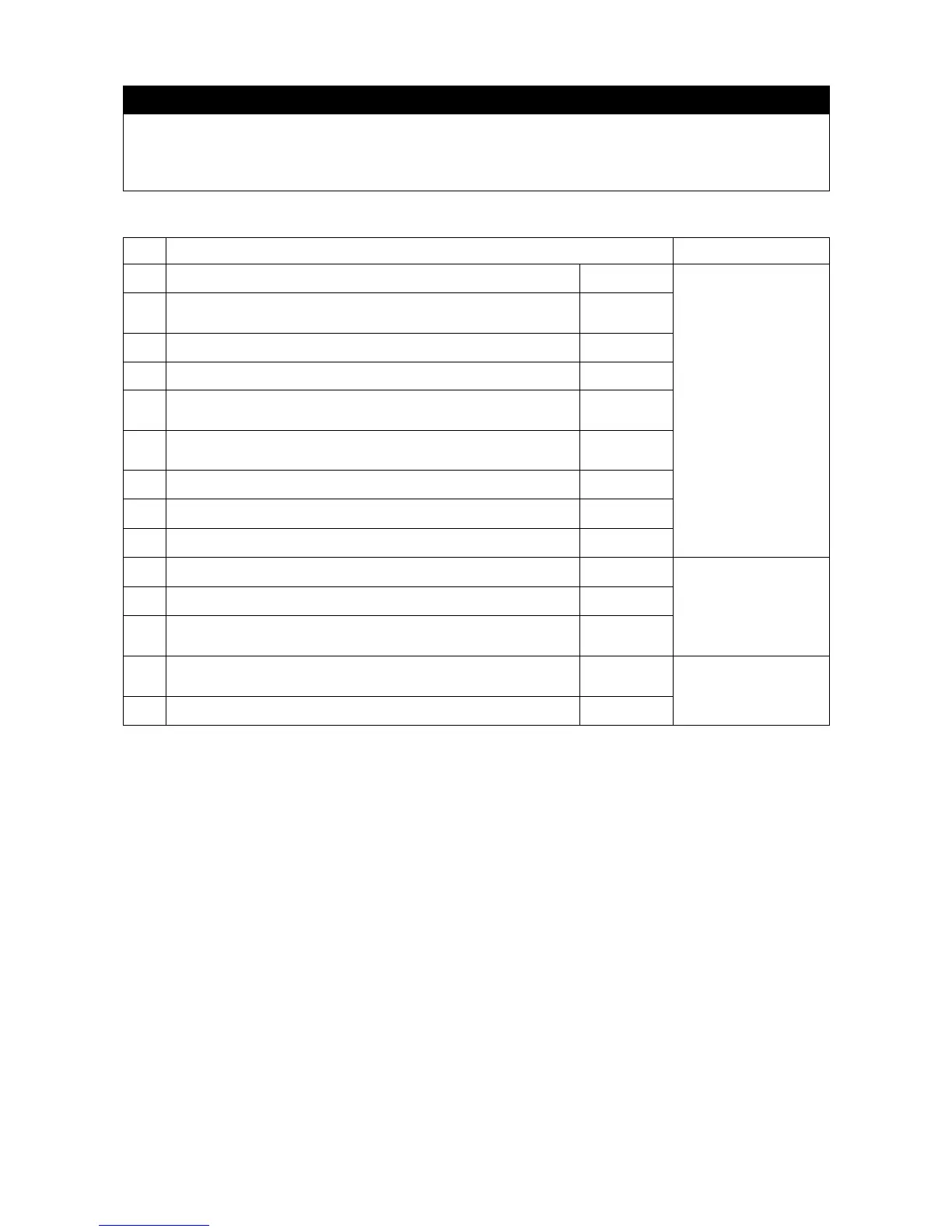

[3] GREASING OF MACHINE UNITS

CAUTION

• Grease type varies with greasing points. Failure to grease properly may shorten the

machine life. Follow the table “Grease type” below.

• Greasing a new machine is required once every 10 hours until the machine attains the

first 100 hours of operation that initial fit emerges.

• Use proper grease specified below according to the greasing points.

No. Greasing point Grease type

1 Greasing of the boom mounting pin 1 place

Lithium grease

2

Greasing of the derricking cylinder bottom mounting

pin

1 place

3 Greasing of the derricking cylinder rod mounting pin 1 place

4 Greasing of the outrigger rotary shaft 4 places

5

Greasing of the outrigger contact cylinder bottom

mounting pin

4 places

6

Greasing of the outrigger contact cylinder rod

mounting pin

4 places

7 Greasing of the slewing gear 1 place

8 Greasing of the sheave 1 place

9 Greasing of the hook block 1 place

10 Greasing of the boom top slide plate 8 places

Neo grease

(grease for boom)

11 Greasing of the boom bottom slide plate 8 places

12 Greasing of both sides and underside of the boom

Each

boom

13

Greasing of the boom extending and retracting wire

ropes

2 pieces

Rope oil

14 Greasing of the winch wire rope 1 piece

1. Using the grease gun, inject grease through corresponding grease plugs indicated in the

arrow (see next page) of the above table “No.1 – 9”.

2. Wipe off old grease squeezed out after greasing.

3. Place the outriggers when greasing the outrigger cylinders.

4. Pull the right operation lever inward to raise the boom slightly for greasing the derricking

cylinder mounting pin and slide plate located on the top surface of the boom.

5. Push the left operation lever forward to extend the boom for greasing both sides and

underside of the boom and wire rope.

6. Apply red rope grease to prevent wire rope abrasion and rust formation.

With the rope surface cleaned, grease the rope with a brush.

Loading...

Loading...