324

[4] OIL REPLACEMENT IN WINCH REDUCTION GEAR CASE

• Various parts are at elevated temperatures immediately after engine operation. Do not

check the oil level immediately. Wait until the oil is cooled.

• Oil or plug may pop out due to the remnant pressure inside the case. Release the

pressure by loosening the plug slowly.

CAUTION

• See “INSPECTION AND MAINTENANCE 6.1 USE OF LUBRICATING OIL ACCORDING TO

TEMPERATURES” for the oil to be used.

• Use seal tape at the thread of the plug to prevent the oil leak and securely tighten the

plug after changing the oil.

• Volume of oil actually to be replaced in the oil pan: 1.8 L

• Prepare a container to drain the oil.

• Have an Allen key ready.

1. Place the machine on a level and firm surface and raise

the boom to approx. 80 degrees.

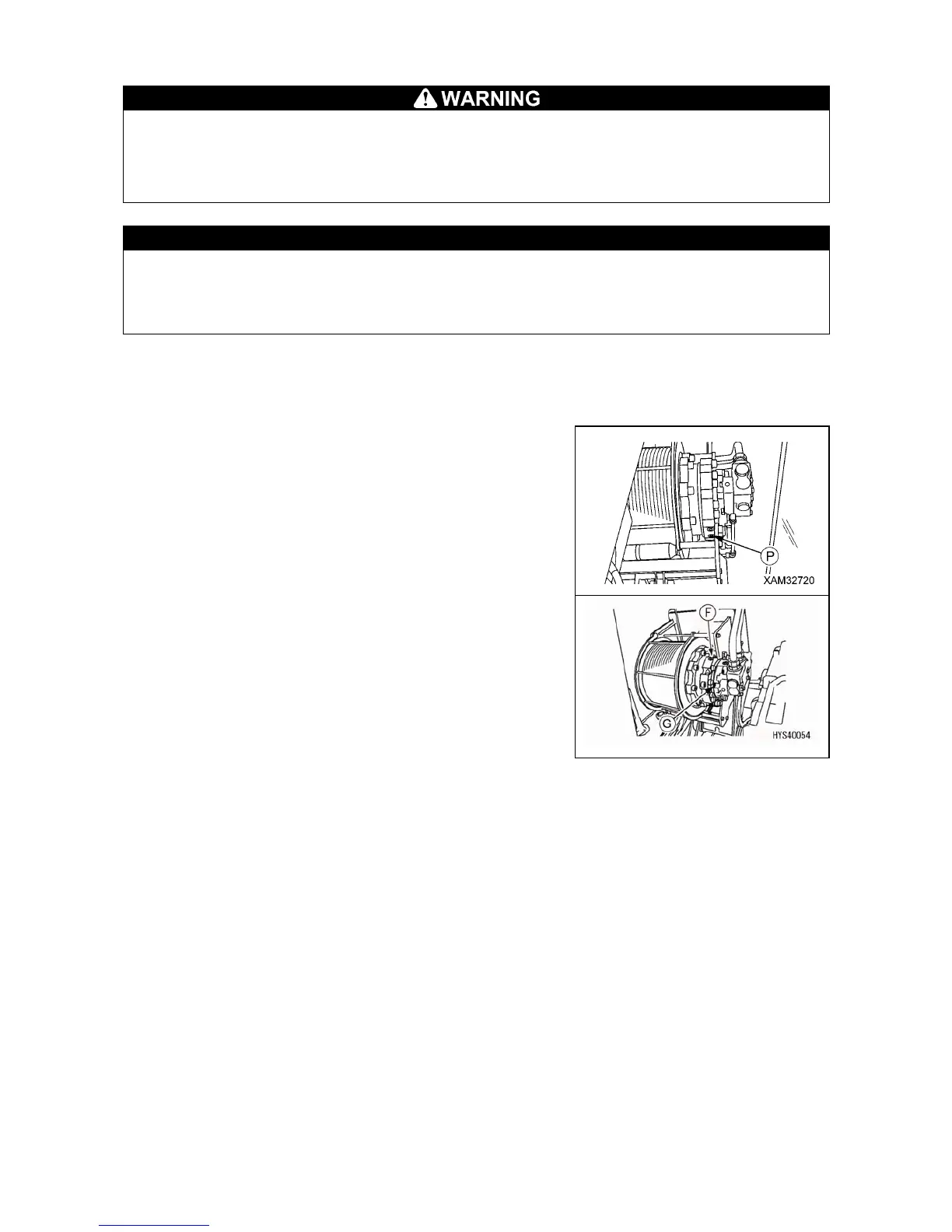

2. Place a container to collect the drained fuel underneath

the drain plug (P).

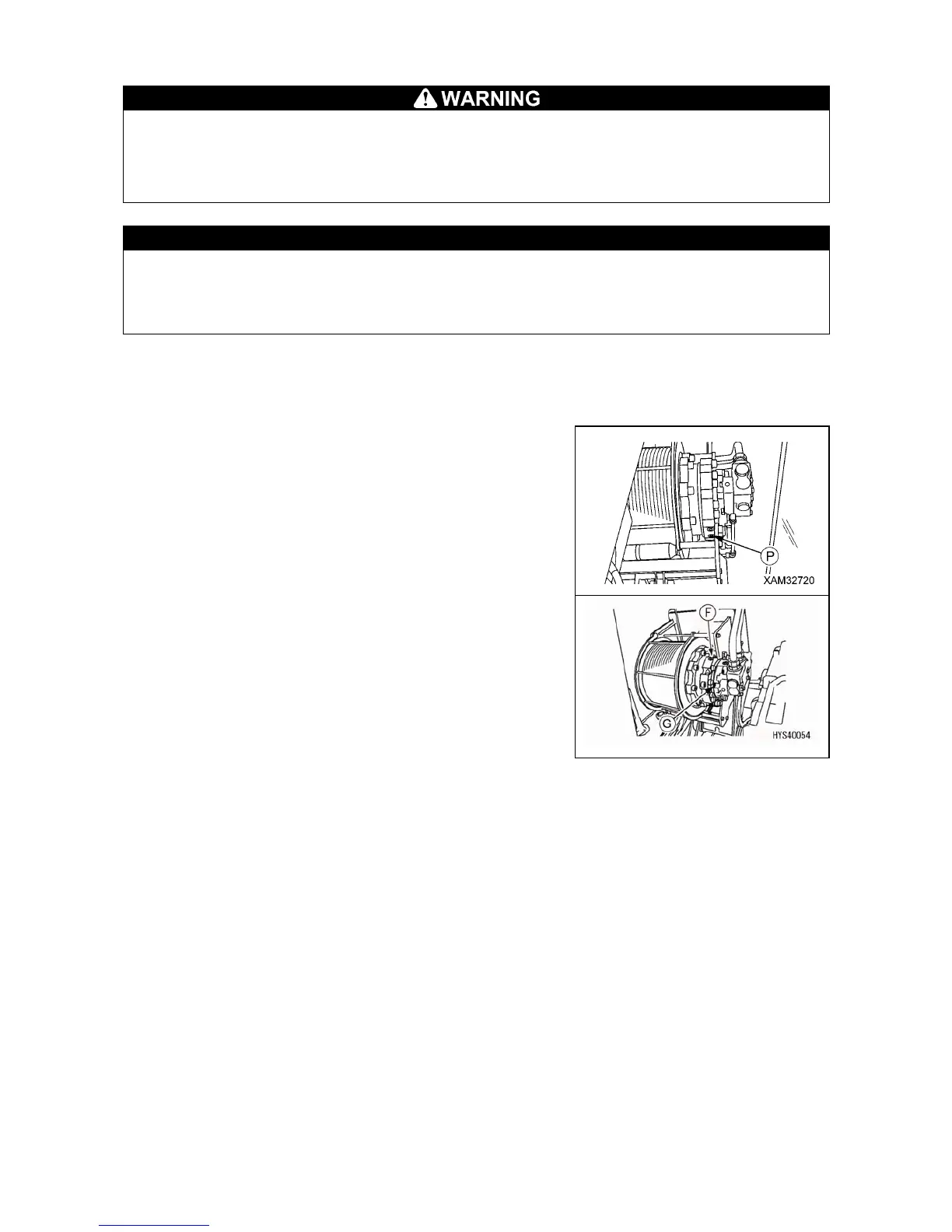

3. Remove the filler plug (F), oil level checking plug (G)

and drain plug (P) using an Allen key and drain the oil.

4. Install and tighten the drain plug (P) securely after

draining.

5. Refill the oil of the exchange amount from the filler plug

(F) hole.

6. If the oil is flowing out from the oil level check plug (G)

hole, securely tighten the oil level check plug (G) and

filler plug (F).

Loading...

Loading...