381

8. INSPECTION AND MAINTENANCE

CAUTION

In this section, only the equipment with the fly jib specification, different from the standard

specification is described.

See “Inspection and maintenance” for details on the machine not described in this section.

8.1 PRE-OPERATION INSPECTION

Check the following in this section before starting the work after attaching a fly jib every day.

[1] Check around fly jib

• Check for any cracks or significant deformation or dirt in parts of a fly jib. Also, check for the loosened,

missing or damaged bolts, nuts, and pins. Especially check each position pin for any significant wear

and damage. Repair if any abnormality is found.

• Check the sheave and guide roller for any significant wear. Replace the parts if any abnormality is

found.

• Check wire rope for over hoist detector weight of the over hoist detector on the fly jib tip for any

significant damage or deformation. Repair if any abnormality is found.

• Check code reel on the left side of fly jib for any significant damage or deformation. Also, check for any

damage on the code reel cables and make sure they operate smoothly. Repair if any abnormality is

found.

• Check for slack wiring, lose connections and any trace of burning. Repair if any abnormality is found.

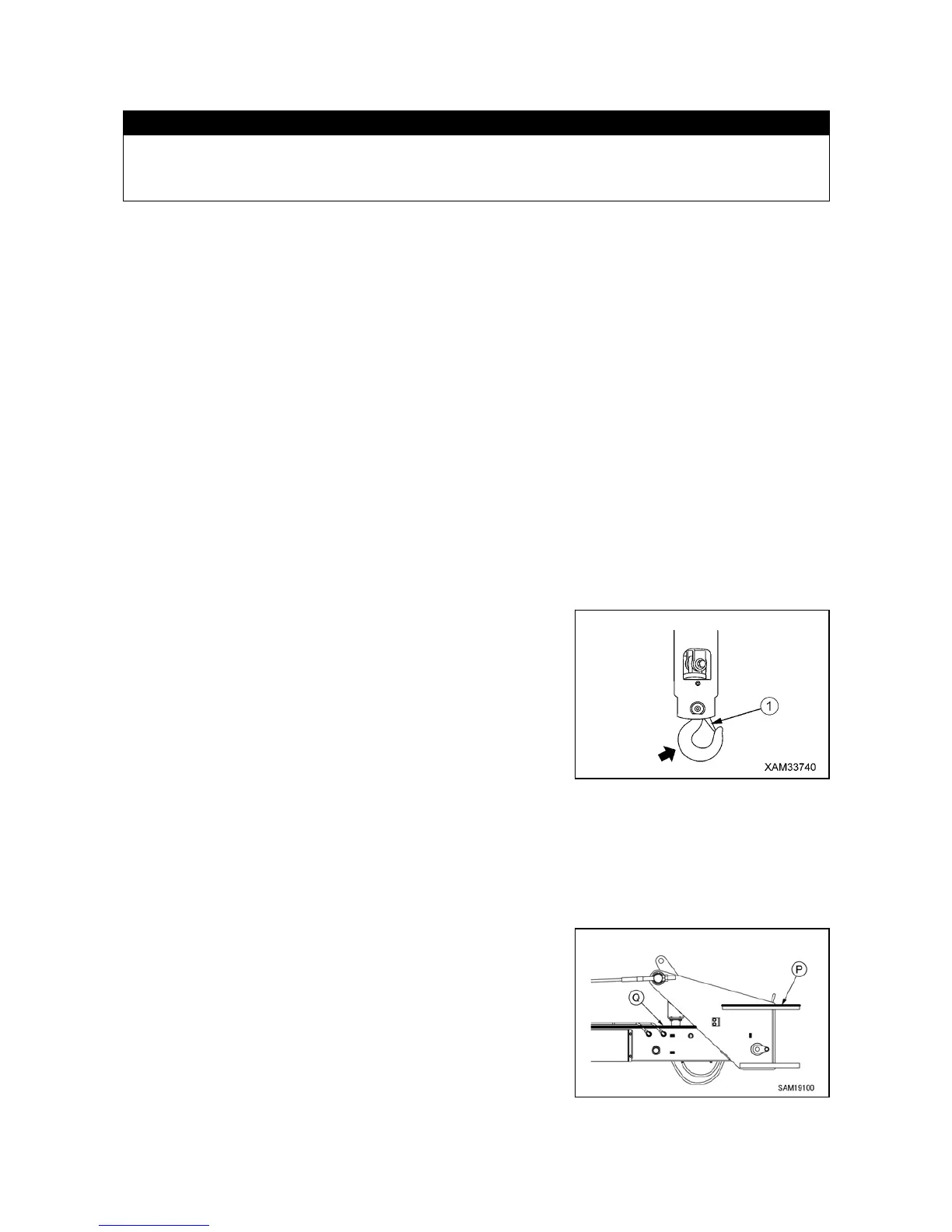

[2] INSPECTION OF HOOK BLOCK

• Check that the wire rope latch (1) is working properly.

Repair if any abnormality is found.

• Rotate the hook and check that it rotates smoothly and

there is no noise coming from the trunnion.

Repair if any abnormality is found.

• Check the hook for any cracks, significant deformation or

dirt.

Repair if any abnormality is found.

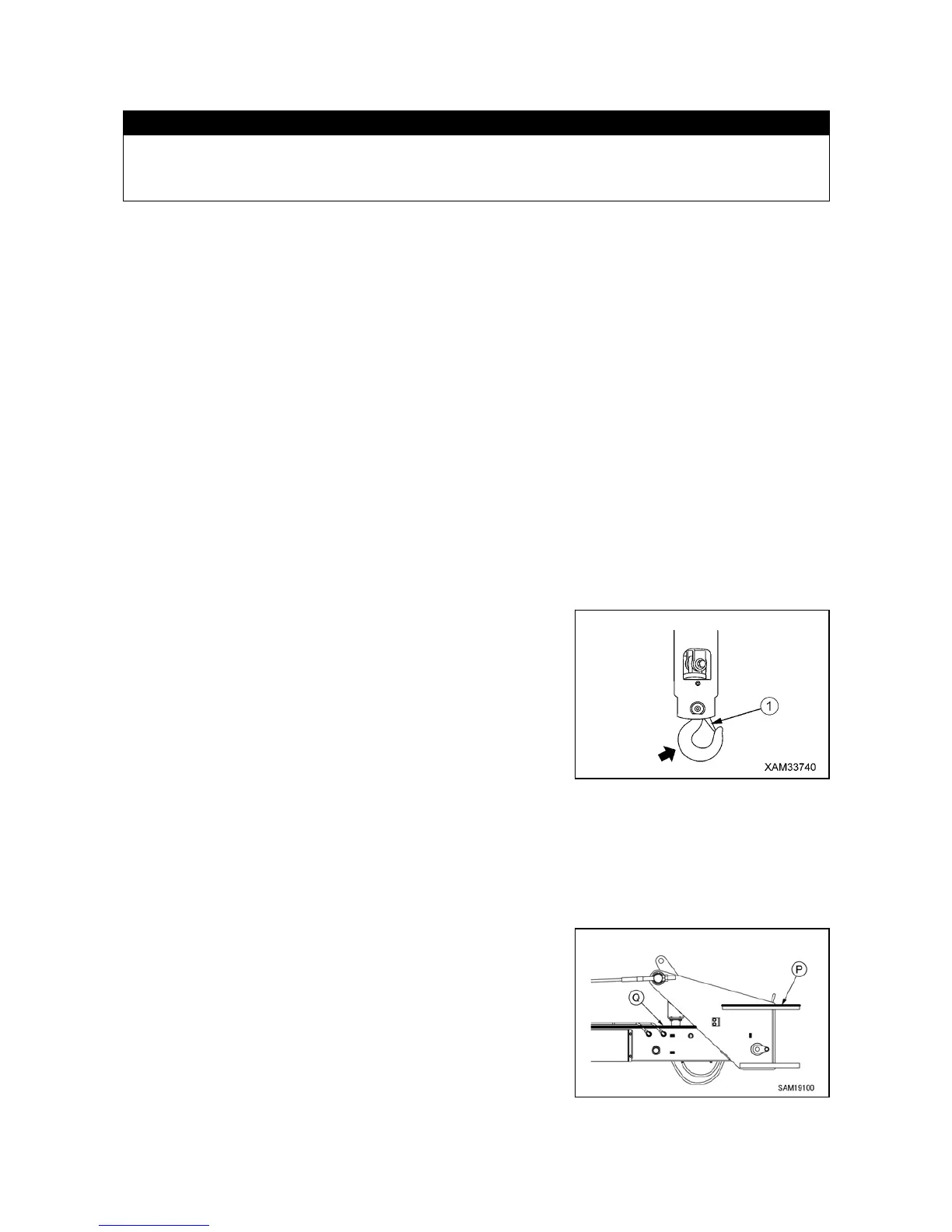

[3] INSPECTION AND ADJUSTMENT OF DERRICK WIRE ROPE

[Inspection of derrick wire rope]

1. Fully extend the fly jib derrick cylinder.

2. Make sure the fly jib base surface (P) and No.1 fly jib

surface (Q) are parallel.

If these are not parallel, refer to the section “Adjustment of

derrick wire rope” and adjust to parallel.

Loading...

Loading...