215

5.2 CORRETIVE ACTIONS AGAINST TWISTED WIRE ROPE

Be sure to wear thick leather work gloves when handling wire ropes.

CAUTION

On occasion, reverse the ends of the wire rope. Turn the rope end at the hook block side

for the end at the winch drum side.

This practice helps to extend wire rope service life.

If the wire rope is twisted, eliminate the twist in the following steps:

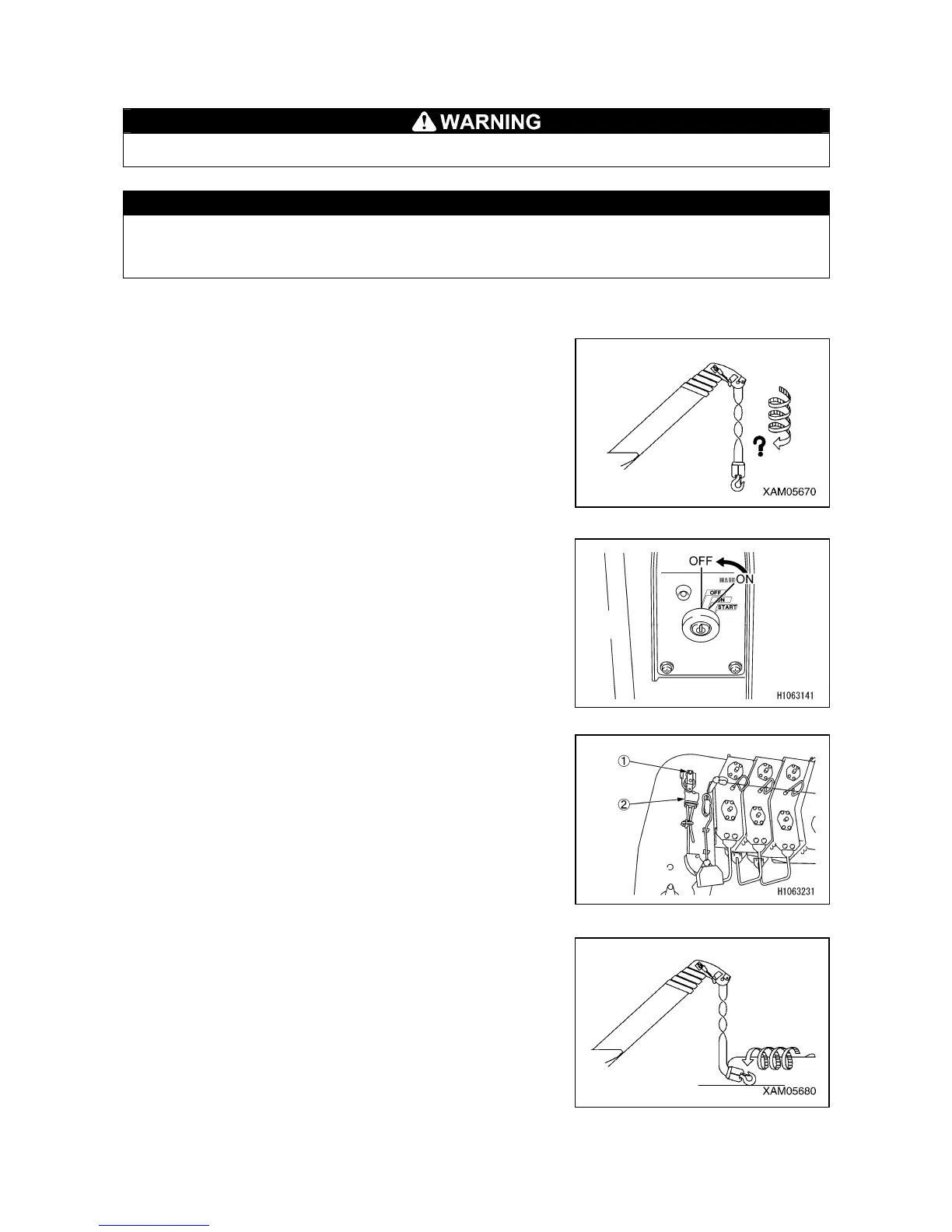

1. Check the twisting direction and how many times the

wire rope has been twisted.

2. Shift the right control lever into “Down” (push it forward)

to rest the hook block on the ground.

If the hook block cannot be unwound, shift the right

control lever into the “Lower” side (push it to the right) to

lower the boom, or shift the left control lever into the

“Retraction” side (pull it toward you) to retract and lower

the boom.

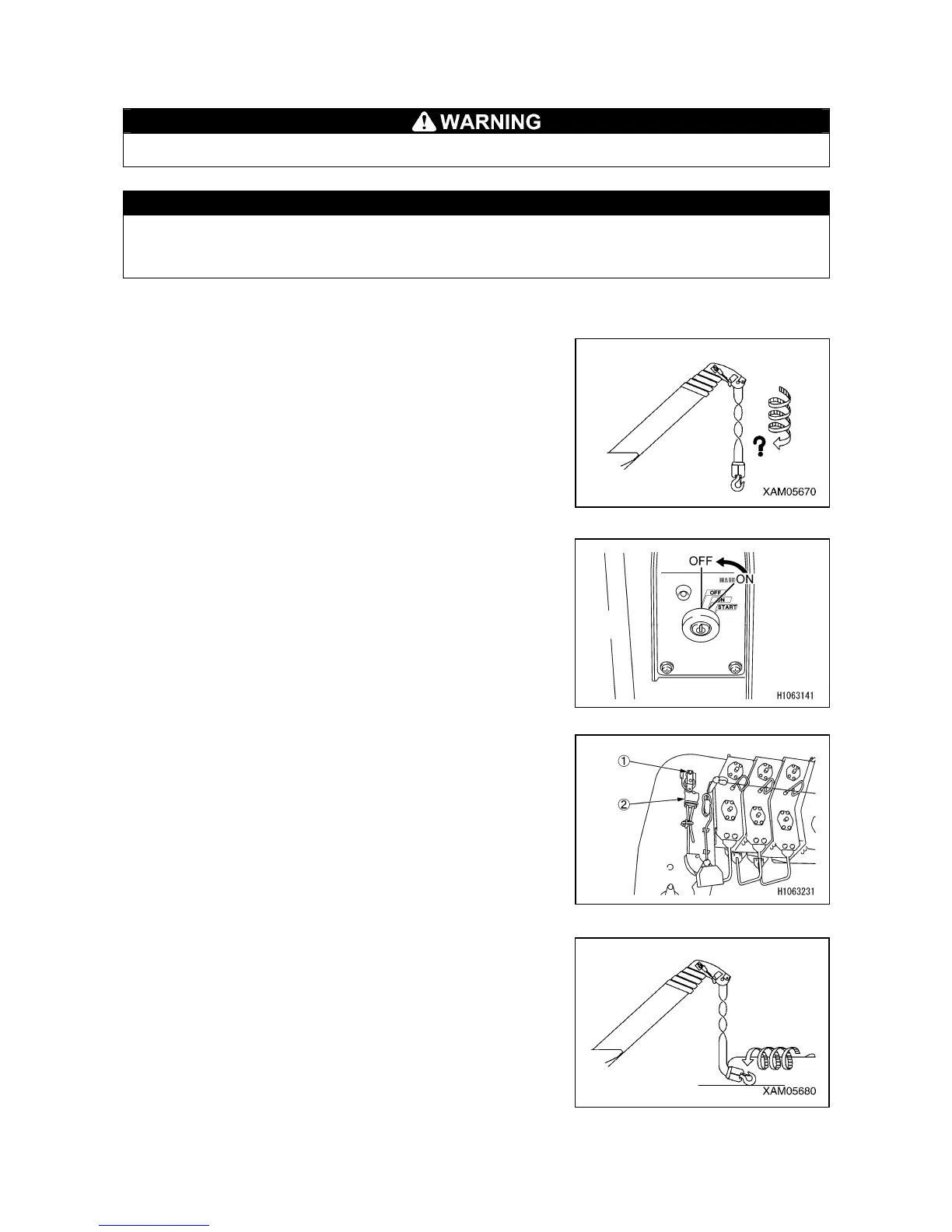

3. Turn the starter switch to the “OFF” position to stop the

engine.

4. Remove the fixing pin (1) securing the wedge socket,

and remove the wedge socket (2).

5. Hold the end of the wire rope, and forcibly twist it in the

direction opposite to the twisting direction identified in

step 1 (in the opposite direction from the direction in

which the wire rope tends to twist by itself when the

hands are released). Repeat this the predetermined

number of times, which can be obtained by multiplying

the number of twisted times by “n” (the number of wires

hung). When you are finished, put back the wire rope

into place.

Loading...

Loading...