214

5. HANDLING WIRE ROPE

5.1 CRITERIA FOR WIRE ROPE REPLACEMENT

CAUTION

• The criteria for replacing wire ropes is common to all the wire ropes for winching,

telescoping the boom, and slinging.

• The diameter of the wire rope is measured at points where the wire repeatedly runs

through the sheave. A mean value needs to be determined through 3 way

measurement.

• Do not use old wire rope regardless of the frequency of use.

• See “INSPECTION AND MAINTENANCE 9.2 [3] REPLACEMENT OF WINCH WIRE ROPE”

for details.

• Contact us or our sales service agency for replacing or repairing the wire ropes.

[1] WIRE ROPE NOMINAL DIMENSION

• Wire rope for winch: IWRC 6×Fi (29) 0/0 ø10 mm × 150 m

• Wire rope for extending boom No.5: IWRC 6×Fi (29) 0/0 ø12.5 mm × 8.96 m

• Wire rope for extending boom No.5: IWRC 6×Fi (29) 0/0 ø9 mm × 17.04 m

[2] CRITERIA FOR WIRE ROPE REPLACEMENT

A wire rope undergoes wear and tear over time.

Prompt replacement is required if any of the following

appears in the wire rope.

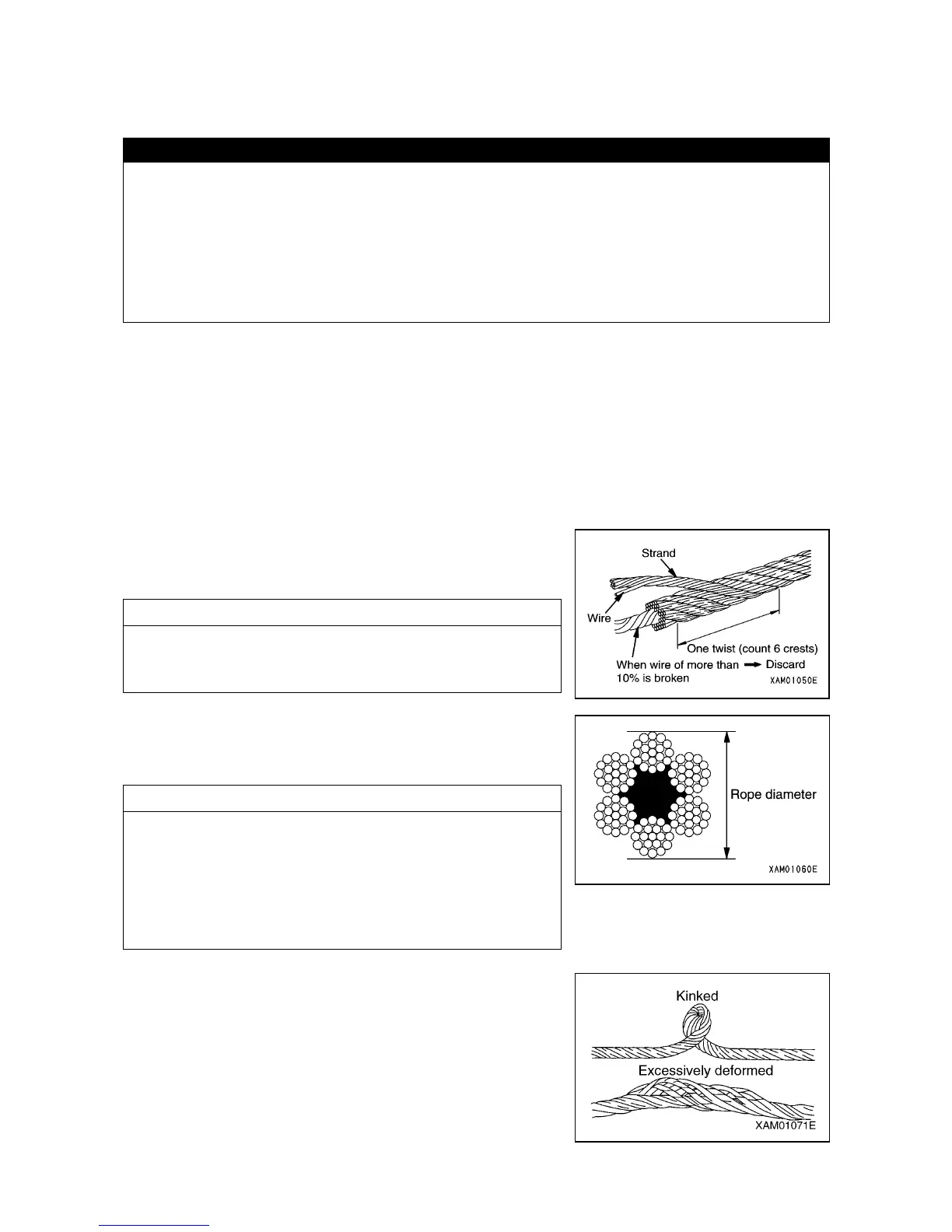

• 10 % or more of strands (except a filler wire) in 1 twist (6

crests) of a wire rope are broken.

NOTES

When 9 strands or more for the winch, or 13 strands or

more for the telescoping boom has been broken, replace

them with new ones.

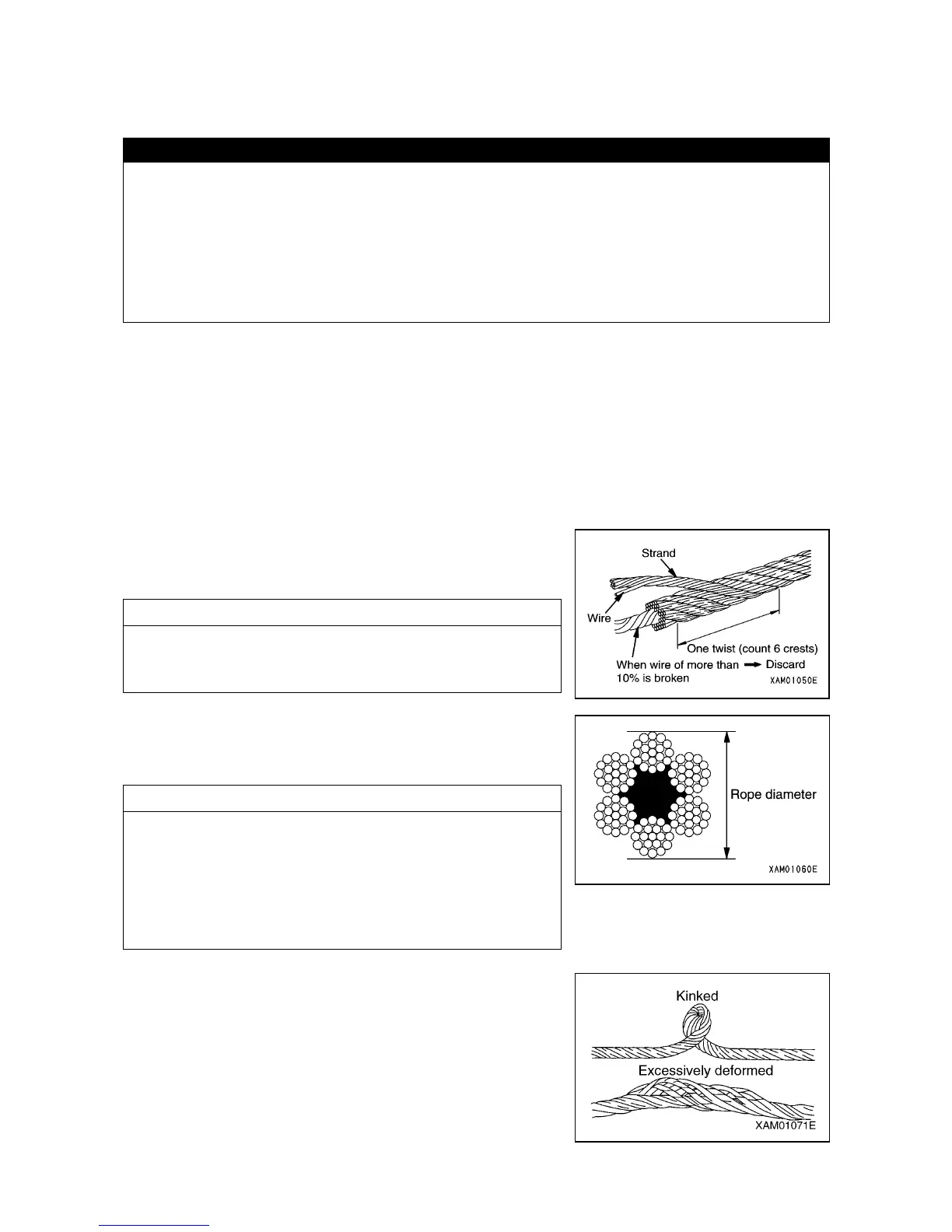

• When the amount of decrease in diameter due to

abrasion damage reaches 7 % or more of the nominal

diameter of the wire rope.

NOTES

• For a wire rope of which the diameter is ø9 mm, replace

when its diameter becomes 8.4 mm.

• For a wire rope of which the diameter is ø10 mm, replace

when its diameter becomes 9.3 mm.

• For a wire rope of which the diameter is ø12.5 mm,

replace when its diameter becomes 11.7 mm.

• A kink is formed.

• Considerable deformation or corrosion is developed.

• A faulty end socket is used.

Loading...

Loading...