HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-20

Published 11-06-15, Control # 040-13

Operating Pressure Checks

It will be necessary to monitor pressure and pump command

on the diagnostic screens of the digital display during the

following procedures. Do not confuse pump command with

handle command on the display.

Boom Hoist Down

1. Stop the engine.

2. Loosen lock nut on adjusting screw at down

multifunction valve in boom hoist pump.

3. Turn adjusting screw out until it stops. Then turn

adjusting screw in 1-3/4 turns.

4. Start and run engine at 1,500 RPM and operate boom

hoist in down direction (no wire rope or load on drums)

Drum should turn freely. If not, proceed as follows:

a. Stop boom hoist drum.

b. Turn down adjusting screw in 1/4 turn.

c. Repeat steps 4

through 4b until drum turns freely.

5. Hold adjusting screw and securely tighten lock nut.

Boom Hoist Up

1. Stop the engine.

2. Disconnect electric plug from boom hoist brake solenoid

valve (Figure 2-24

). This will stall boom hoist pump.

NOTE: If equipped with a luffing hoist, disconnect electric

plug from luffing hoist brake solenoid valve also

(Figure 2-25

).

3. Start and run the engine at 1,500 RPM.

4. Scroll to Drum 4 (boom hoist) diagnostic screen. Monitor

pump pressure and pump command while moving

control handle.

5. Slowly pull boom hoist control handle back. Diagnostic

screen should indicate 5,500 to 6,500 psi (379 to 448

bar) system pressure before 50% pump command is

reached and boom hoist brake (luffing hoist also if

equipped) must not slip.

6. If specified pressure is not indicated or brake(s) slips,

determine cause and correct.

7. Connect electric plug to boom hoist (and luffing hoist if

equipped) brake solenoid valve (Figure 2-24

and

Figure 2-25

).

Swing

1. Stop the engine.

2. Disconnect electric plug from swing brake solenoid

valve (Figure 2-25

). This will stall swing pump.

3. Start and run the engine at 1,500 RPM.

4. Scroll to SWING diagnostic screen. Monitor pump

pressure and command while moving control handle.

5. Slowly move swing control handle in both directions, one

at a time, to check swing pressure.

6. Swing pressure in both directions should be 5,500 to

6,500 psi (379 to 448 bar) before 50% pump command

is reached, and brake must not slip.

7. If specified pressure is not indicated in either direction or

brake slips, determine cause and correct.

8. Connect electric plug to swing brake solenoid valve

(Figure 2-25

).

CAUTION

Overheating Damage!

Do not stall hydraulic system longer than 10 seconds

during following pressure checks or components may be

damaged from overheating.

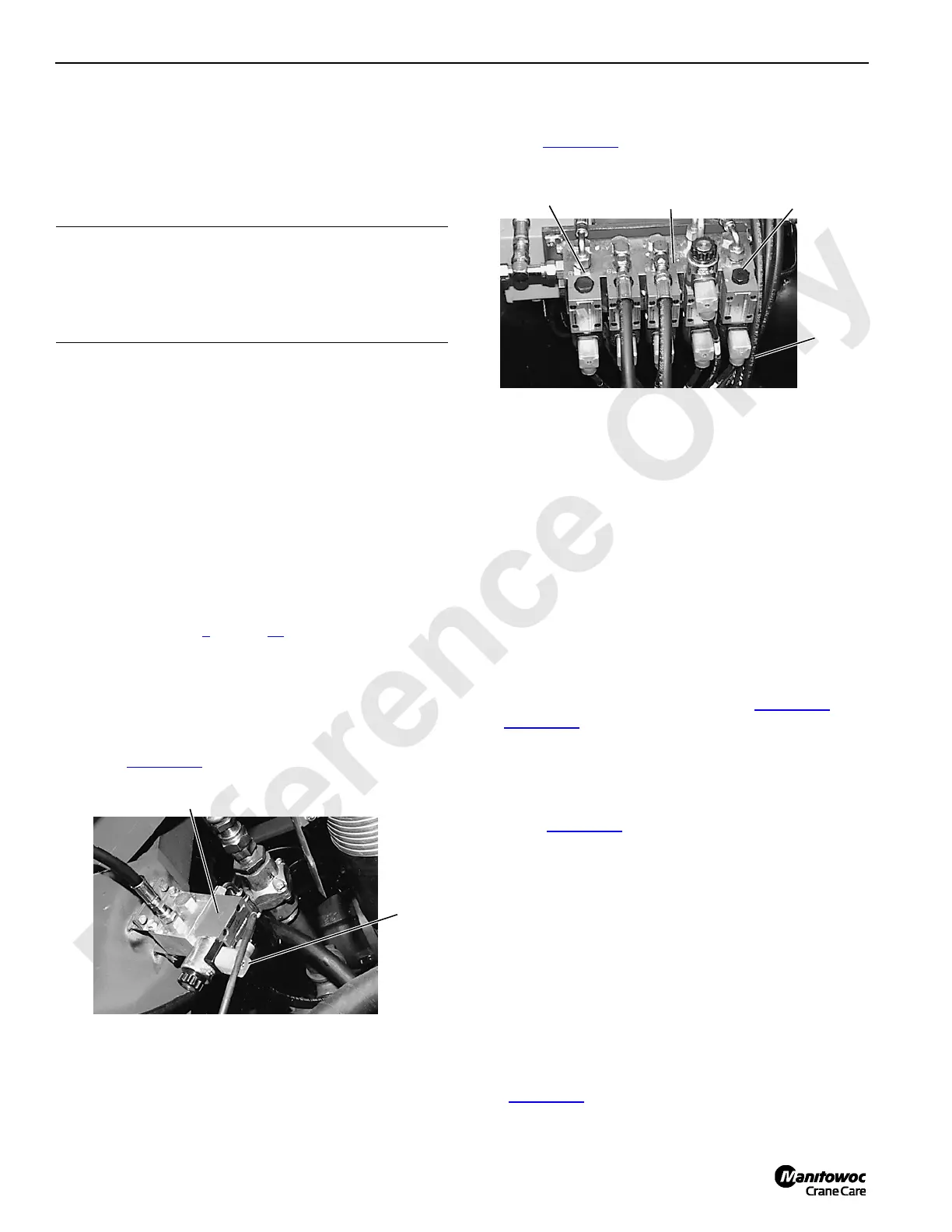

FIGURE 2-24

Electric

Plug

P924

Boom Hoist Brake Solenoid valve

Access at Left Rear Inboard Side of Rotating Bed

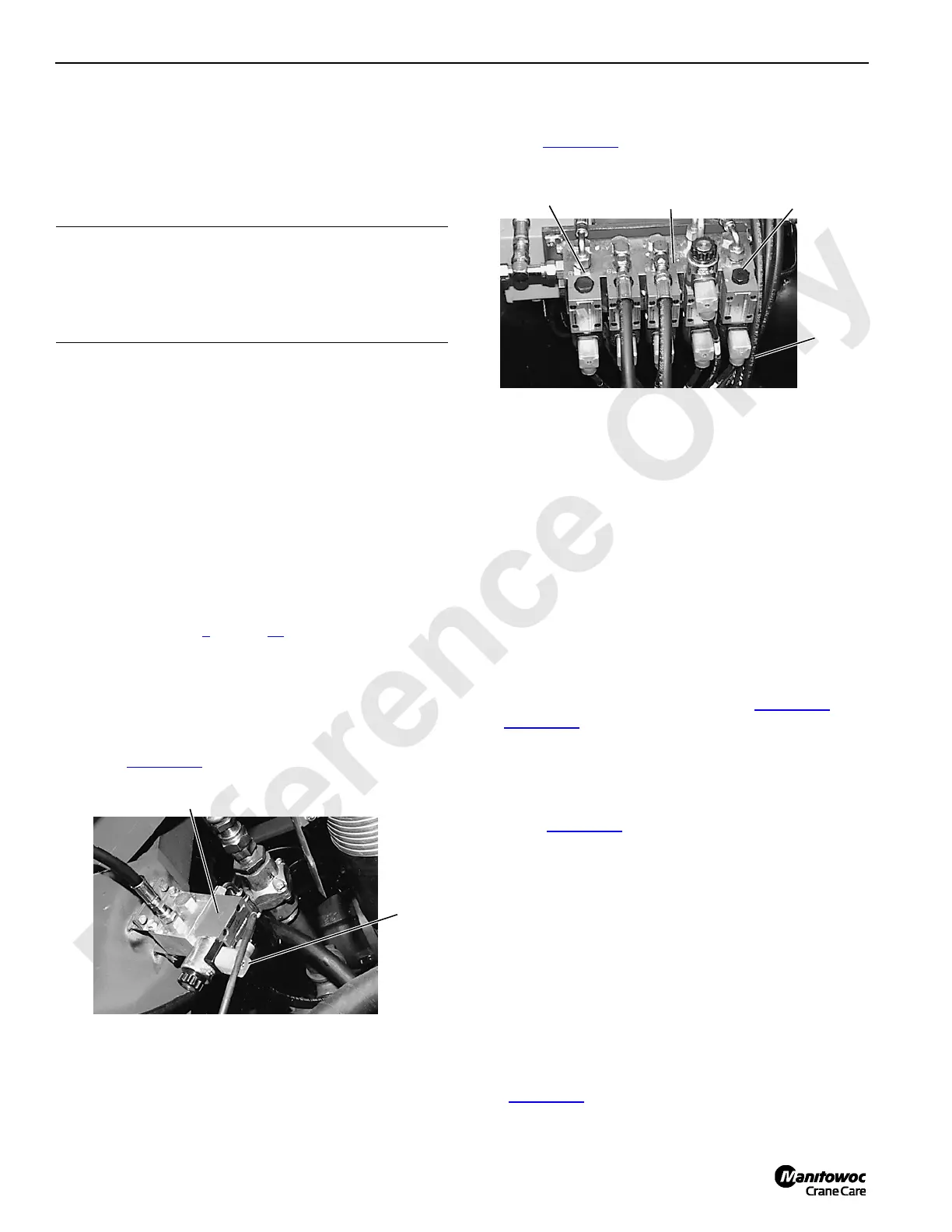

FIGURE 2-25

Access Through Center Hole in Rotating Bed

P973

Electric

Plug

(typical)

Swing Brake

Solenoid Valve

Travel Brake

Solenoid Valve

Luffing Hoist Brake

Solenoid Valve

Loading...

Loading...