BOOM 2250 SERVICE/MAINTENANCE MANUAL

4-16

Published 11-06-15, Control # 040-13

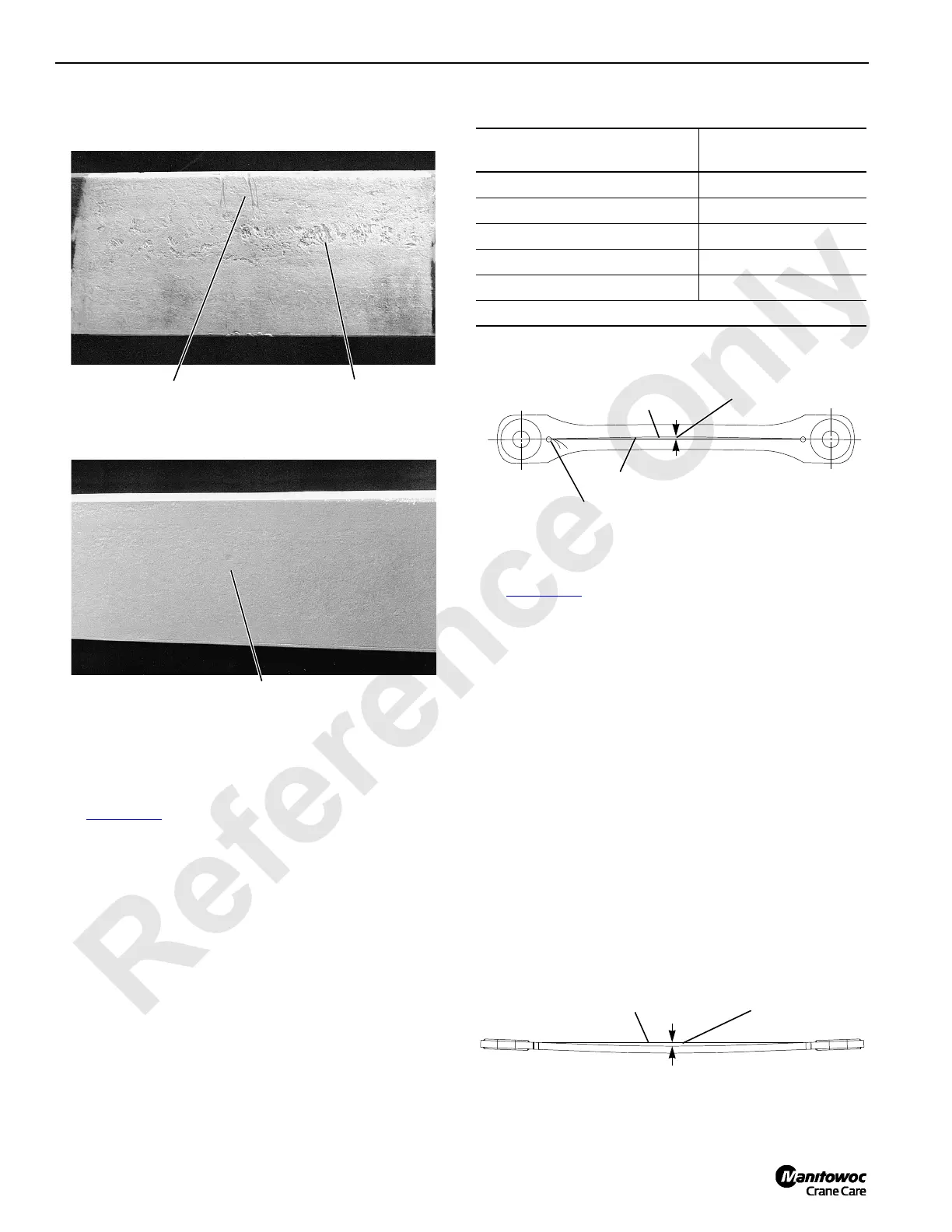

Straightness

See Figure 4-17 for the following procedure.

1. Stretch a line (string or wire) from pin storage hole at one

end of strap.

2. Stretch line as tight as possible and tie it off at other end.

3. Mark strap center line. Do not use center punch!

4. If string does not align with center line, measure

distance from center line to line.

5. If deviation from straight is greater than maximum

allowed, remove strap from service.

Flatness

See Figure 4-18 for the following procedure.

1. Lay strap on a flat surface. Do not block or the strap

may sag!

2. Stretch a line (string or wire) across top surface of strap

from pin storage hole at one end of strap.

3. Stretch line as tight as possible and tie it off at other end.

4. Check that line touches top surface of strap at all points

along its length.

5. If string does not touch strap, measure distance from

line to strap.

If deviation from straight is greater than maximum

allowed, remove strap from service.

6. Remove line. Turn strap over.

7. Repeat steps 1-5 above.

Not Acceptable

Abrasion from handling

with chain exceeds allowable limit.

Acceptable

Surface is relatively smooth; within allowable limit.

Not Acceptable

Surface is badly pitted;

exceeds allowable limit.

P325

P326

Corrosion or Abrasion

FIGURE 4-16

Strap Length

(L)

Maximum Deviation

Allowed

5 to <10 ft (1,5 to <3,0 m) 0.060 in (1,5 mm)

10 to <20 ft (3,0 to <6,1 m) 0.125 in (3,2 mm)

20 to <30 ft (6,1 to <9,1 m) 0.125 in (6,4 mm)

30 to <40 ft (9,1 to <12,2 m) 0.375 in (9,5 mm)

40 to <50 ft (12,2 to <15,2 m) 0.50 in (12,7 mm)

< = less than

Pin Storage

Hole (typical)

Center line

String

Deviation

from Straight

A1086

Straightness (gradual

or sweeping bend)

FIGURE 4-17

Distance between

Line and Strap

Line

A1086

Flatness (includes twisted straps)

FIGURE 4-18

Loading...

Loading...