HOISTS 2250 SERVICE/MAINTENANCE MANUAL

5-28

Published 11-06-15, Control # 040-13

• Running Ropes (working lines) — six randomly

distributed broken wires in one lay length, or three

broken wires in one strand of one lay length.

• Rotation Resistant Rope — two randomly distributed

broken wires in six rope diameters or four randomly

distributed broken wires in thirty rope diameters.

• Standing Ropes (pendants) — more than two broken

wires in one lay length in sections beyond the end

attachment, or more than one broken wire at the end

attachment (Figure 5-24

).

• All Ropes — one outer wire broken at the point of

contact with the core. The broken wire protrudes or

loops out of the rope structure.

United States Steel states “Replacement criteria for

galvanized strand boom suspension pendants are

25 percent of the outer wires fractured, or 10 percent

of the total numbers, whichever comes first.”

Wear and Other Damage

See Figure 5-25 for examples of wire rope damage.

It is normal for the outer wires of the rope to wear first

because of friction.

Wire rope must be taken out of service if:

• Rope core protrudes from between outer strands

• Severed corrosion – indicated by pitting – exists

• Obvious damage exists from any heat source to include

– but not limited to – welding, power line strike, or

lightning.

• Kinking, crushing, bird caging, or any other damage

resulting in distortion of wire rope structure exists.

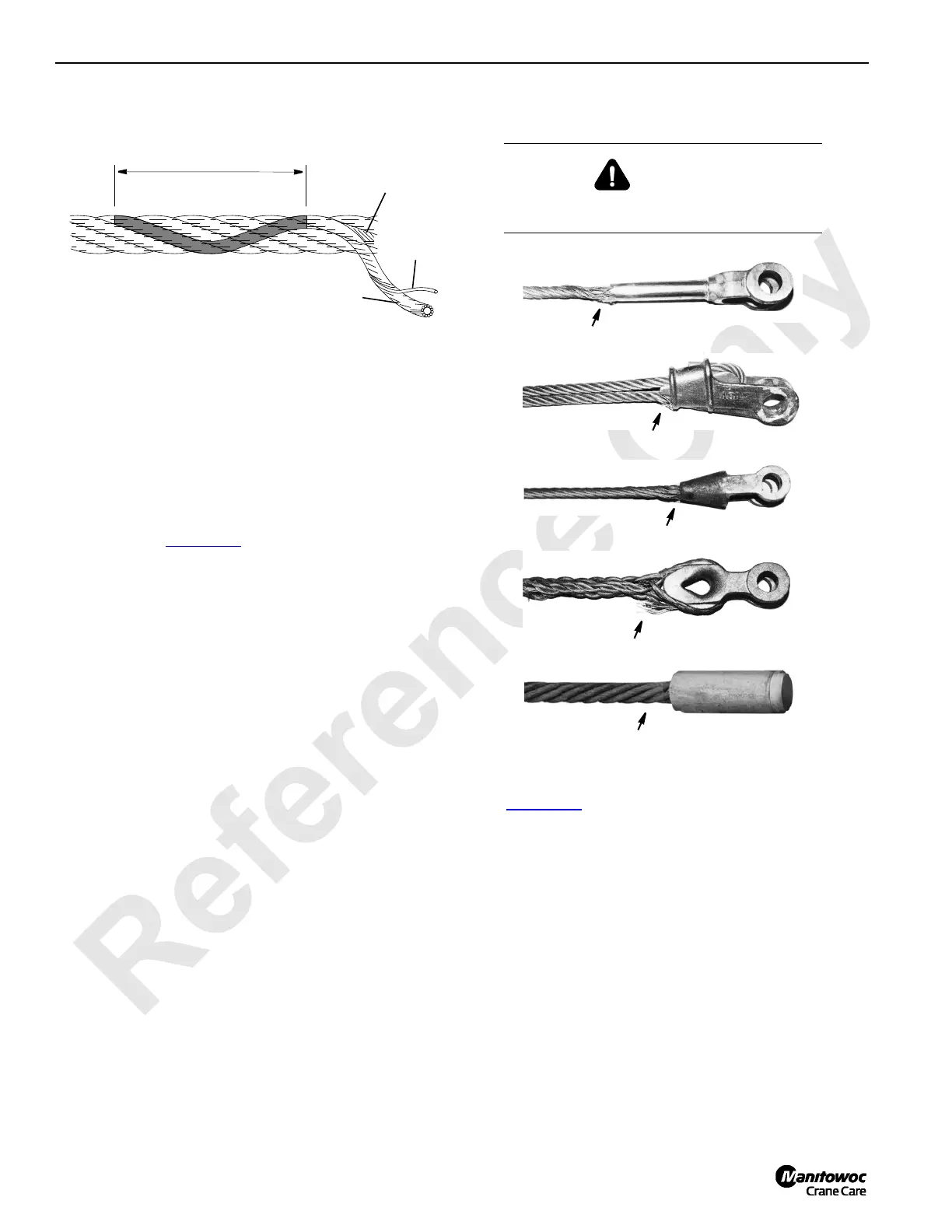

FIGURE 5-23

A925

LAY LENGTH is distance measured along rope in which one

strand makes one complete revolution around core.

Core

One

Wire

One Strand

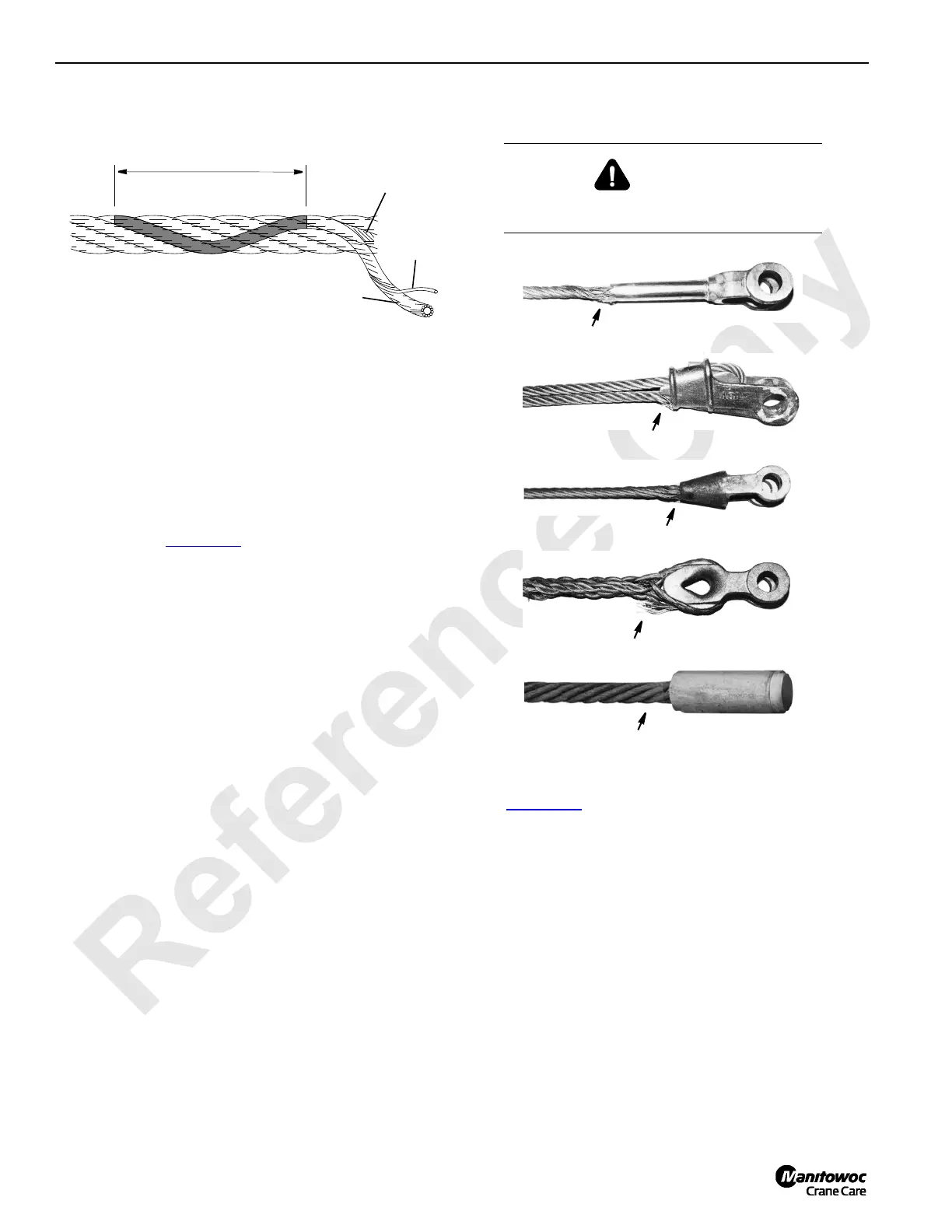

FIGURE 5-24

WARNING

Replace wire rope when more than one

broken wire appears at point marked by arrow.

S140

Poured Zinc Socket

S142

S141

S143

Hand Splice

Swaged Socket

Wedge Socket

S4412-144

Button Socket

Loading...

Loading...