HOISTS 2250 SERVICE/MAINTENANCE MANUAL

5-26

Published 11-06-15, Control # 040-13

WIRE ROPE LUBRICATION

Refer to Section 9.

WIRE ROPE INSPECTION AND

REPLACEMENT

General

The inspection and replacement guidelines which follow

comply with United States regulations.

It is impossible to predict when a wire rope will fail; however,

frequent and periodic careful inspection by a qualified

inspector will indicate when the potential for failure exists.

See Wire Rope Lubrication topic in Section 9 of this manual.

Keeping Records

A signed and dated report of the wire rope’s condition at

each periodic inspection must be kept on file at all times. The

report must cover all inspection points listed in this section.

The information in the records can then be used to establish

data which can be used to determine when a wire rope

should be replaced.

It is recommended that the wire rope inspection program

include reports on the examination of wire rope removed

from service. This information can be used to establish a

relationship between visual inspection and the rope’s actual

internal condition at the time of removal from service.

Inspecting Wire Rope

Frequent Inspection

Visually inspect all running ropes in service once each work

shift and observe the rope during operation. Pay particular

attention to areas of the rope where wear and other damage

is likely to occur:

• Pick-Up Points — sections of wire rope that are

repeatedly stressed during each lift, such as those

sections in contact with sheaves.

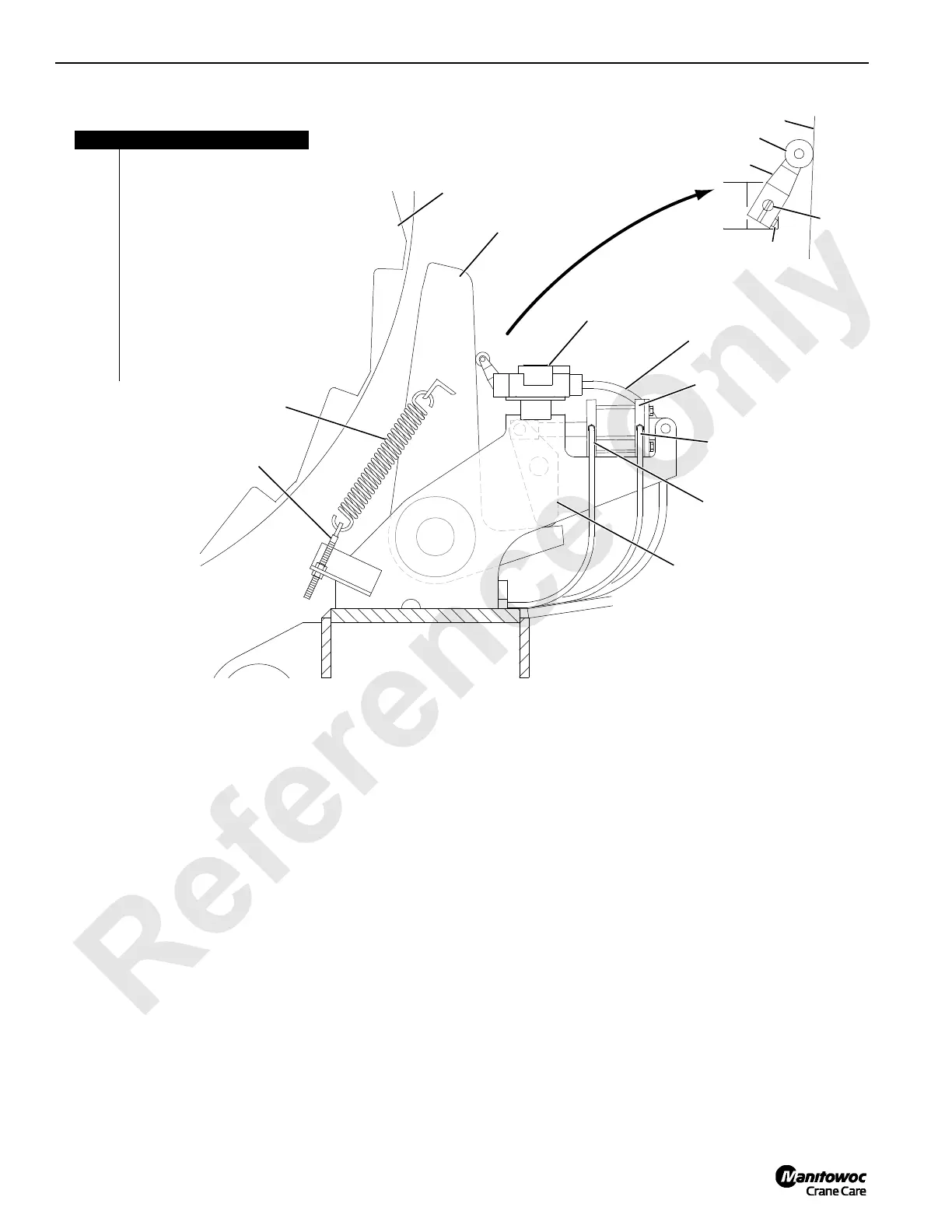

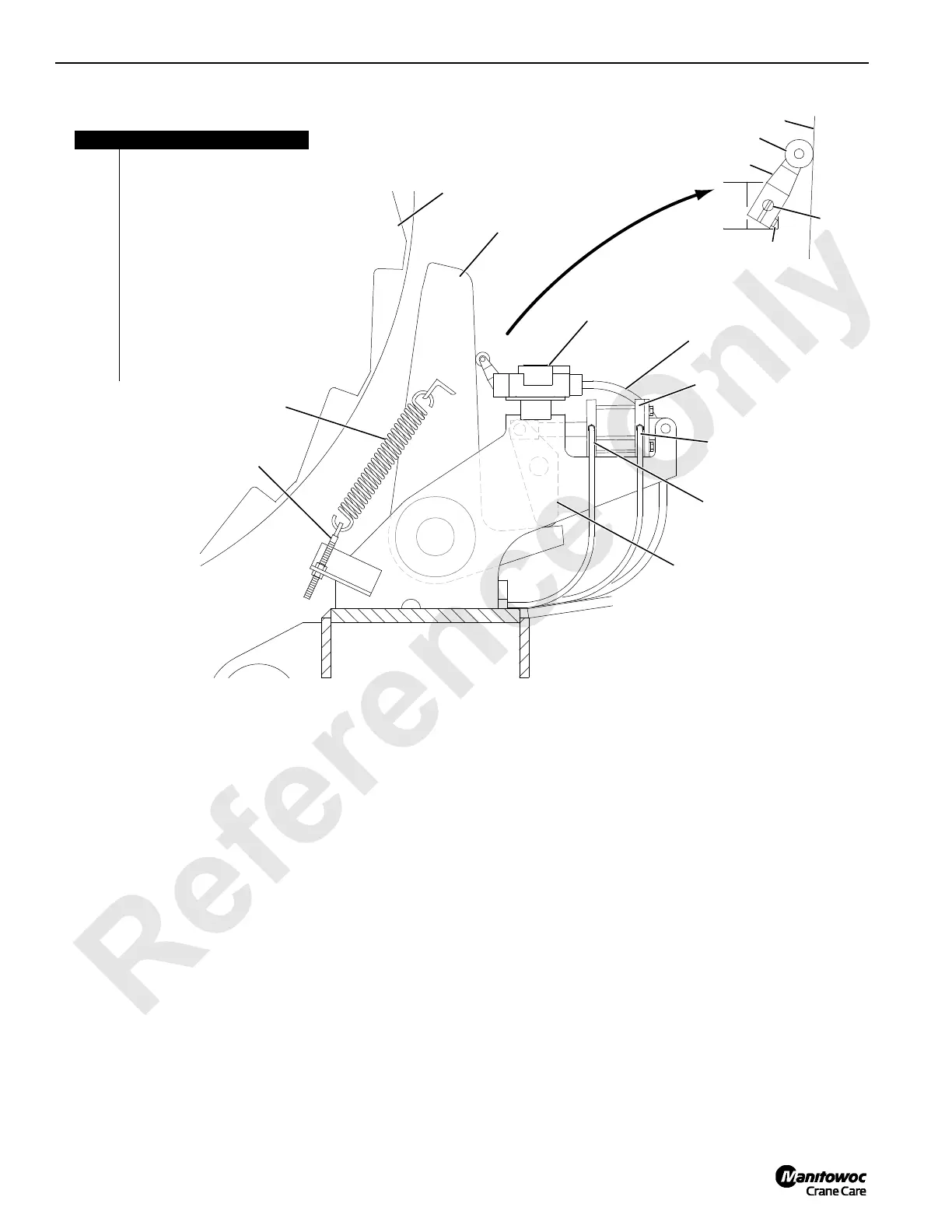

A1066

Connect Electric Wires To

Normally OPEN Terminals

Inside Limit Switch

Front Drum Shown;

Rear Drum Similar

FIGURE 5-21

Item Description

1Pawl

2Roller

3Lever

4Screw

5 Shaft

6 Ratchet

7 Limit Switch

8Cylinder

9 Air In Disengage Pawl

10 Air In Engage Pawl

11 Cam

12 Eyebolt

13 Spring

1

12

11

10

9

1

2

3

4

5

6

7

8

13

Loading...

Loading...