HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-34

Published 11-06-15, Control # 040-13

Every 6,000 hours or 36 months

Rebuild the air dryer including the desiccant cartridge.

The desiccant change interval may vary from crane to crane.

Although typical desiccant cartridge life is three years, many

will perform adequately for a longer period of time. In order to

take maximum advantage of desiccant life and assure that

replacement occurs only when necessary, it is important that

Operation and Leakage tests be performed.

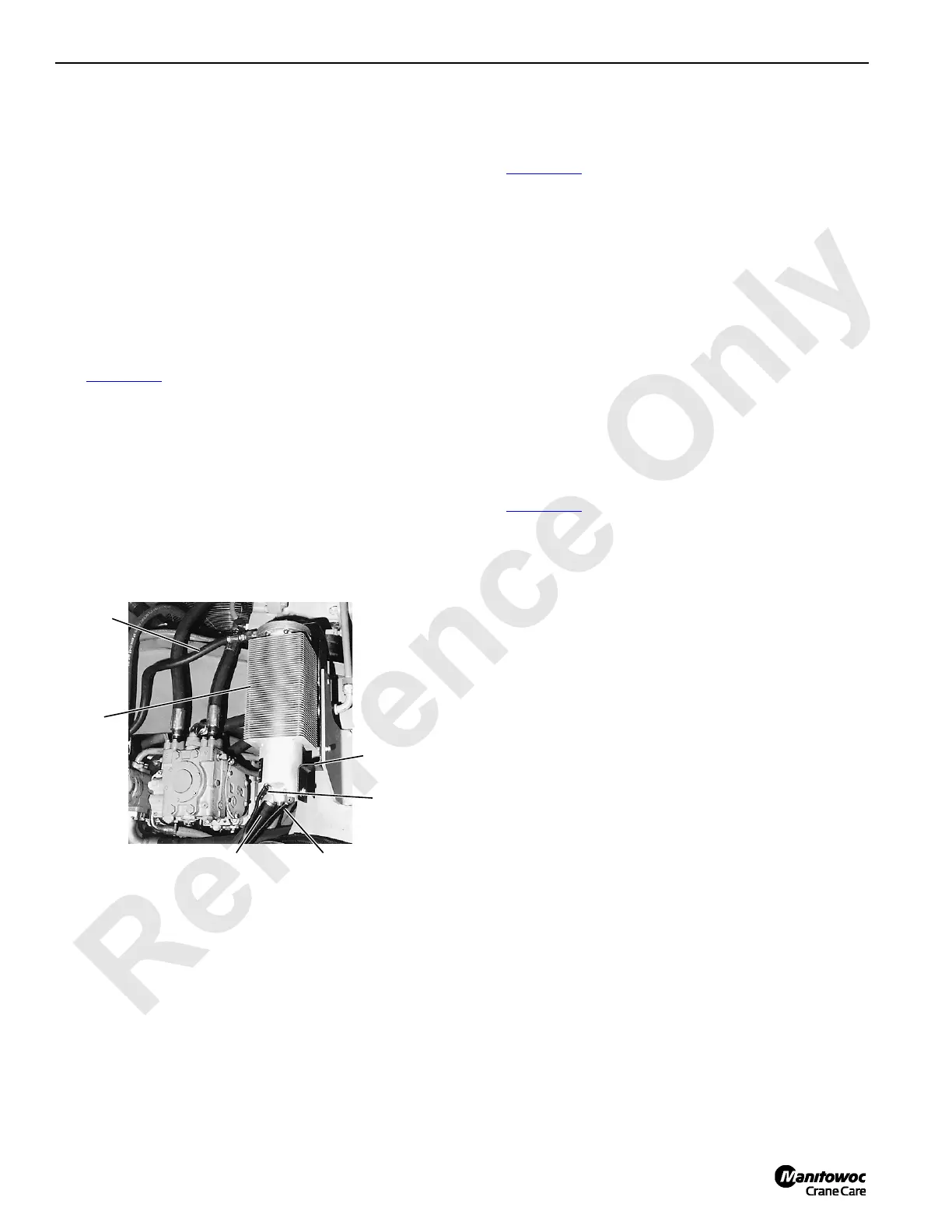

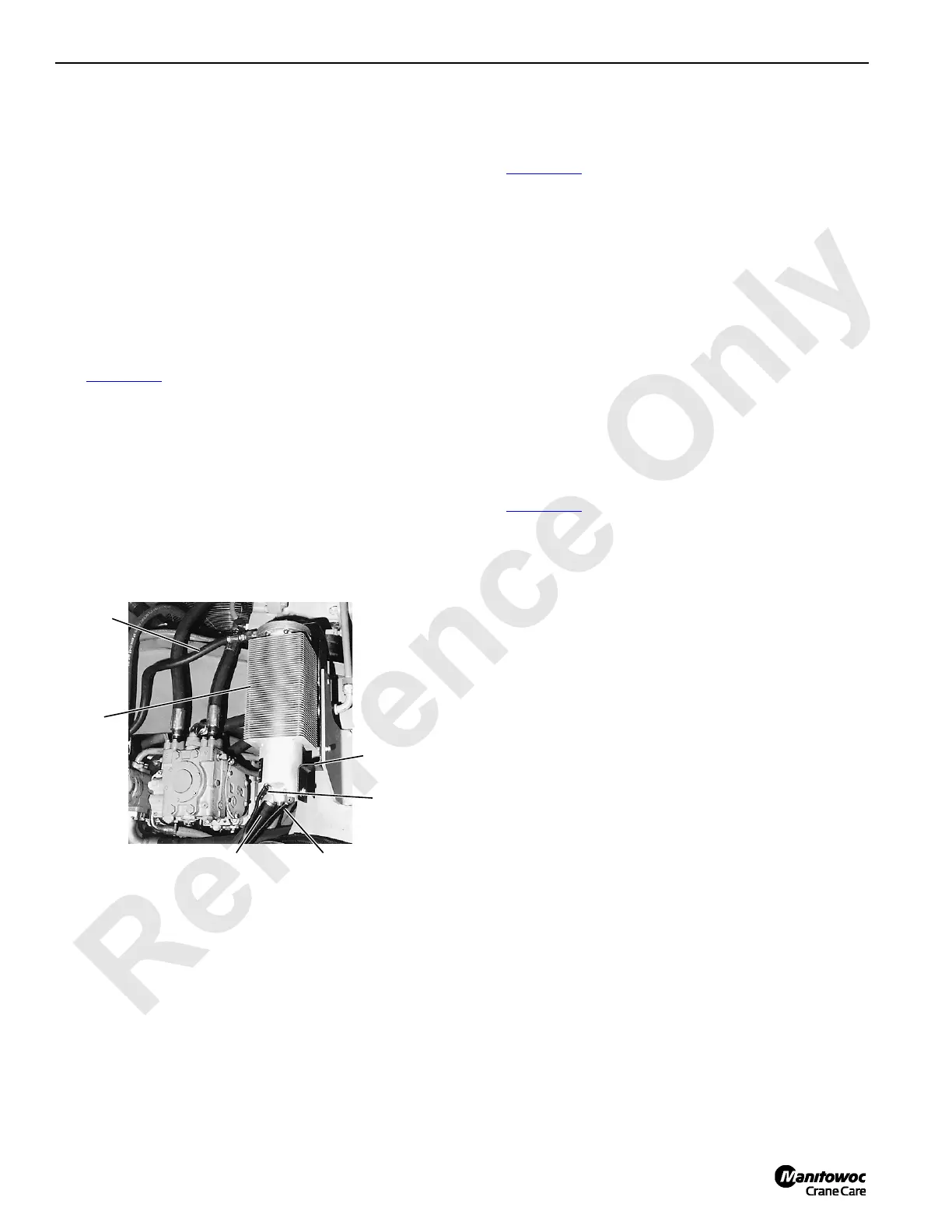

AIR DRYER MAINTENANCE (PAST

PRODUCTION)

Description

See Figure 2-35 for the following procedure.

The air dryer is a filtering unit that cleans and dries the air

delivered to the air system by the air compressor.

Compressed air enters the air dryer where oil, water and

solid contaminants are removed and collected in a sump. Air

then flows up through the air dryer where any remaining

moisture is removed before the air enters the air tank. All

contaminants and any air remaining in the air dryer are then

discharged through an unloader valve during the

compressor cutout cycle.

Operation

Compressor Cut-In

See Figure 2-36 for the following procedure.

1. When pressure in the air tanks drops to the cut-in

pressure, the compressor unloader valve closes.

2. The compressor unloader valve then exhausts the air

from the pilot lines. This action closes the air dryer

unloader valve and signals the compressor to start

compressing air.

NOTE: For operation of moisture ejector, see Moisture

Ejector Valve Maintenance topic in this section.

3. Air from the compressor enters the air dryer where oil,

water and other solid contaminants are removed and the

air is dried.

4. The air flows through the check valve in the top of the air

dryer and into the air tanks.

Compressor Cut-Out

See Figure 2-36 for the following procedure.

1. When pressure in the air tanks reaches the cut-out

pressure, the compressor unloader valve opens. This

action signals the compressor to stop compressing air.

NOTE: The check valve in the top of the air dryer closes to

prevent the air in the system from exhausting

through the air dryer unloader valve.

2. Pressure in the pilot line to the air dryer unloader valve

causes it to open, allowing air, oil, water and dirt to

discharge from the air dryer.

FIGURE 2-35

P777

Air Dryer Installation

(Left Side of Rotating Bed)

From Moisture

Ejector

Mounting

Bracket

From Air

Compressor

Heater

Wires

Air

Dryer

To A i r

Tan ks

Loading...

Loading...