HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-46

Published 11-06-15, Control # 040-13

N-1 PRESSURE REDUCING VALVE

MAINTENANCE

Operation

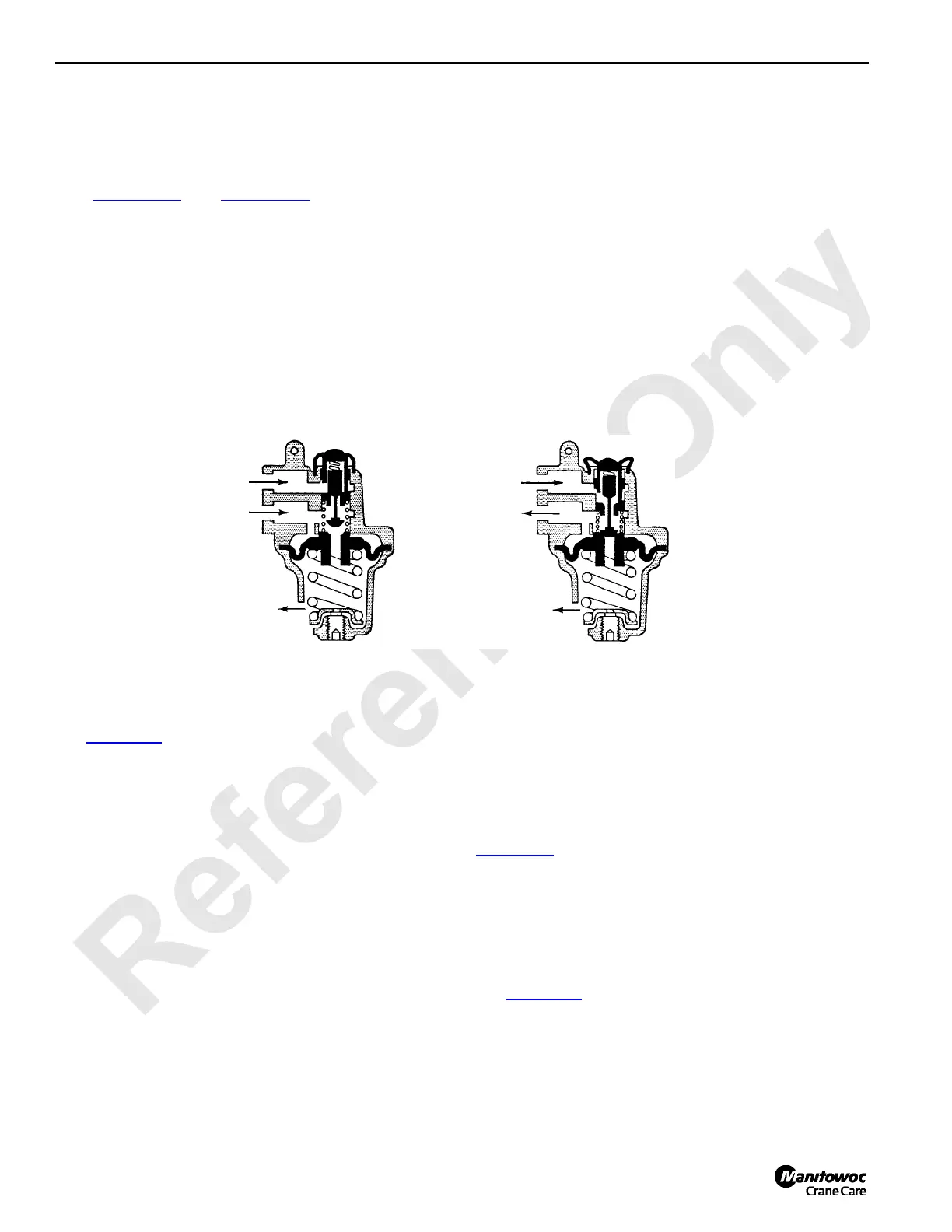

See Figure 2-46 and Figure 2-47 for the following

procedures.

Air pressure from the main supply passes from the in port to

the out port through the unseated inlet valve of inlet and

exhaust valve unit (1). The inlet valve is held off of its seat by

control spring (2) which forces diaphragm (3) and seat (4)

upward. While seat is in the upward position, the exhaust

valve is closed and the inlet valve is held open.

Air pressure at the out port also passes through a sensing

port to the top of diaphragm. When the pressure at the out

port reaches the setting of control spring it is compressed

and the valve assembly moves down far enough to close the

inlet valve and keep the exhaust valve closed. As long as air

pressure at the out port and spring force are balanced, the

inlet and exhaust valve will remain closed.

The valve will automatically compensate for downstream

pressure changes keeping the control circuit at the

predetermined or set pressure. Pressure changes may be

caused by line leakage, temperature changes, or load thrust.

If air pressure at the out port increases over that called for by

the spring setting, the diaphragm will deflect downward

moving exhaust valve seat away from the inlet and exhaust

valve unit and vent the excess pressure. If pressure drops

below that called for by the spring setting, control spring

forces diaphragm upward and exhaust valve seat moves the

inlet valve from its seat, opening the in port to the out port to

restore the pressure called for.

Maintenance

See Figure 2-47 for the following procedures.

Maintenance periods should be scheduled in accordance

with frequency of use and working conditions of valve.

One complete valve should be kept in stock for each four

valves in service. During the maintenance period, change

out the complete valve with the “stand-by” unit. This will

reduce production time loss and allow inspection and

replacement of worn parts in a clean location at a more

convenient time.

NOTE: The operating portion of the valve can be removed

without disturbing the pipe connections.

Remove the valve portion by loosening nut (5) and stud (6).

No special tools are required to maintain the valve.

Completely disassemble the valve. Wash all metal parts in

non-flammable solvent and all rubber parts in soap and

water. Rinse each part thoroughly and blow dry with a low-

pressure air jet. Arrange the parts on a clean surface in the

order of the exploded view.

Examine each part carefully. Flex the diaphragm and

packing rings, and if cracked or worn, replace them. Replace

all parts that may not provide satisfactory service until the

next maintenance period.

Reassemble the valve using the exploded view in

Figure 2-47

as a guide. Lubricate each part before it is put

into place. Use No. 107 Lubriplate on all metal to metal

surfaces and No. 55 Pneumatic Grease on all rubber parts.

Equivalent greases to those recommended can be used.

Store the reconditioned valve in a moisture proof bag.

Adjustments

See Figure 2-47 for the following procedures.

Use adjusting screw (7) to adjust the valve. Turning the

adjusting screw in raises the outlet pressure and turning it

out lowers the outlet pressure.

In

Out

Exhaust

In

Out

Exhaust

Decreasing Pressure

Increasing Pressure

S119

FIGURE 2-46

Loading...

Loading...