INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-98

Published 11-06-15, Control # 040-13

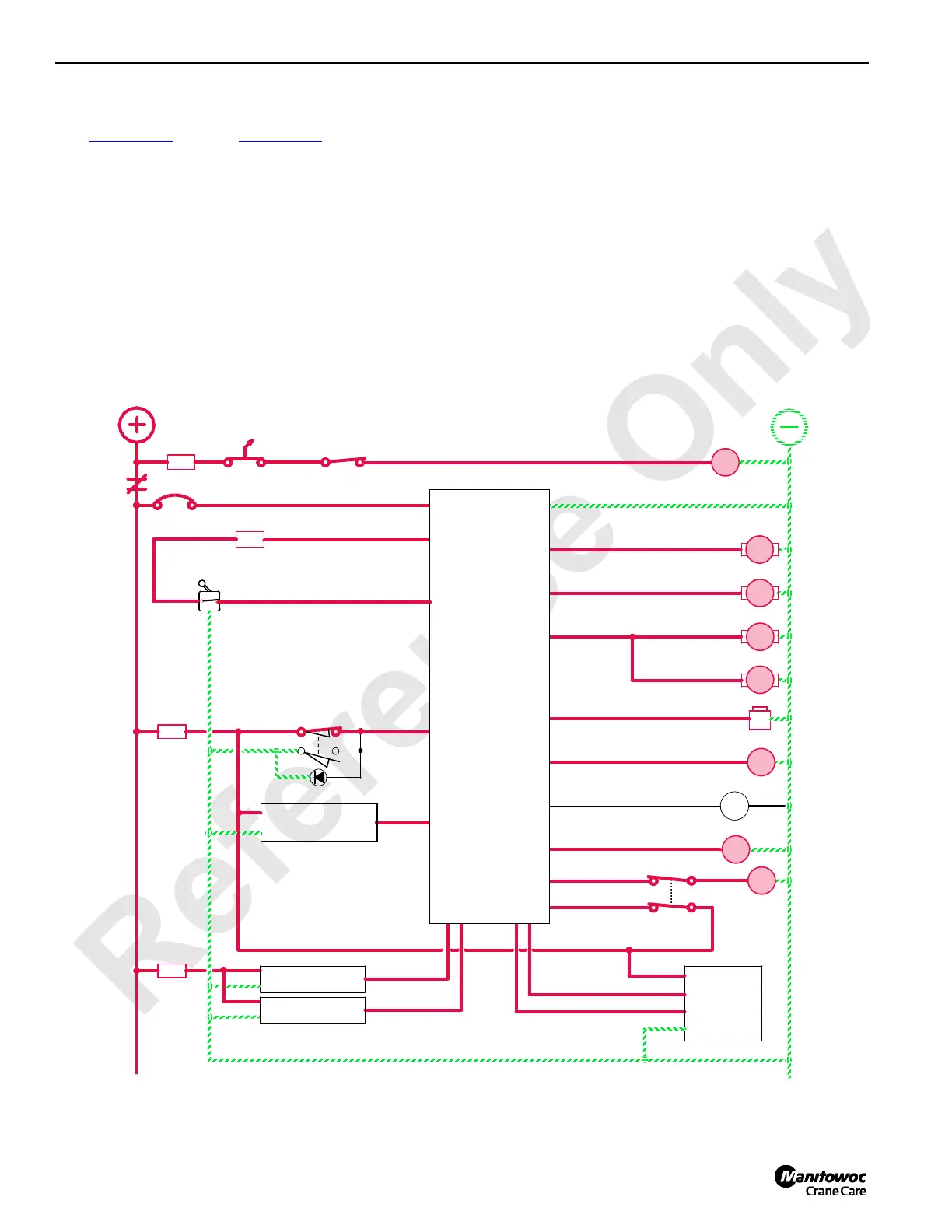

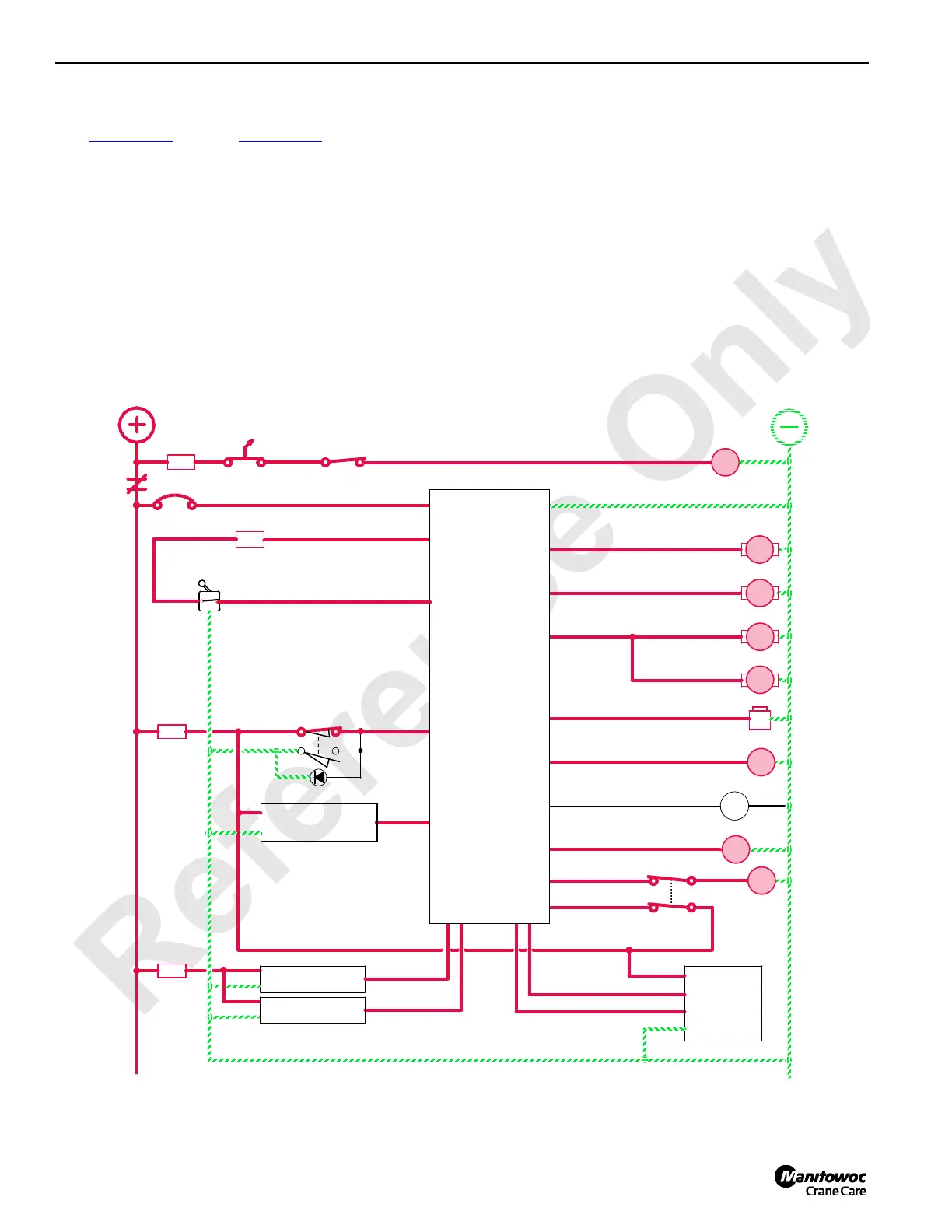

Drum 9 Operation

See Figure 1-62 through Figure 1-65 for the following

procedure.

For MAX-ER configurations drum 9 is mounted in the boom

butt. Source of pressurized hydraulic fluid to operate drum 9

is from the crane crawler travel system or boom hoist system

depending on crane program version.

The left control handle controls drum 9 operation. The

corresponding number 9 green light comes on behind left

control handle. The PC applies drum 9 brakes, controls

crawler travel pump speed, and selects control handle

operation depending on crane mode version. See Operating

Controls topic in Section 3 of MAX-ER Operator Manual for

MAX-ER operation.

Motor loop flushing valves open when system pressure

exceeds 200 psi (14 bar). The sequence/flow control valve

removes 4 GPM (15 L/min) of hot fluid from system by

dumping the fluid in the motor case where it returns to tank.

When drum 9 is operating, the PC monitors input signals

from crawler travel pressure senders and adjust motor

displacement to maintain equal pressure.

The drum flange mounted speed sender monitors drum

speed and controls drum over speed. The speed sender

sends a signal to the crane PC that enables rotation indicator

in drum control handle. This indicator pulsates with a varying

frequency depending on drum rotational speed.

LEFT HANDLE CONTROL

LEFT TRAVEL

SENDER

RIGHT TRAVEL

SENDER

LOWERRAISE

REGULATED 10V DC OUT

8

5A

OFF

3A

8T

88MC

RM17

DRUM 9

FLANGE

ENCODER

80N

A

B

A

B

DRUM 9 LEFT

MOTOR CONTROL

DRUM 9 RIGHT

MOTOR CONTROL

84A

83A

RIGHT TRAVEL

PUMP CONTROL

LEFT TRAVEL

PUMP CONTROL

A

B

B

A

LEFT

ROTATION INDICATOR

88D

TRAVEL/DRUM 9

DIVERTING VALVE

BRAKE

PAWL IN

PAWL OUT

88C

88CA

88E

88N

83DS

8K

84DS

87FA

80P

5DA

5A

8

CAB POWER

OFF

ON

D

B

A

F

8P1

0

8

K1

50 AMP

0

8

10A

5D

5A

88MB

DRUM 9

MINIMUM

BAIL LIMIT

88MA

ENGINE

RUN/STOP

89GA

HS

56

EDC

EDC

PCP

PCP

HS

54

DRUM 9

AS

21

AS

22

DRUM 9

DRUM 9

K1

CRANE

PROGRAMMABLE

CONTROLLER

FIGURE 1-62

HANDLE

90QM

MAST

ACCUMULATOR

SENDER

Loading...

Loading...