Manitowoc Published 11-06-15, Control # 040-13 2-25

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

UNLOADER PILOT VALVE MAINTENANCE

General

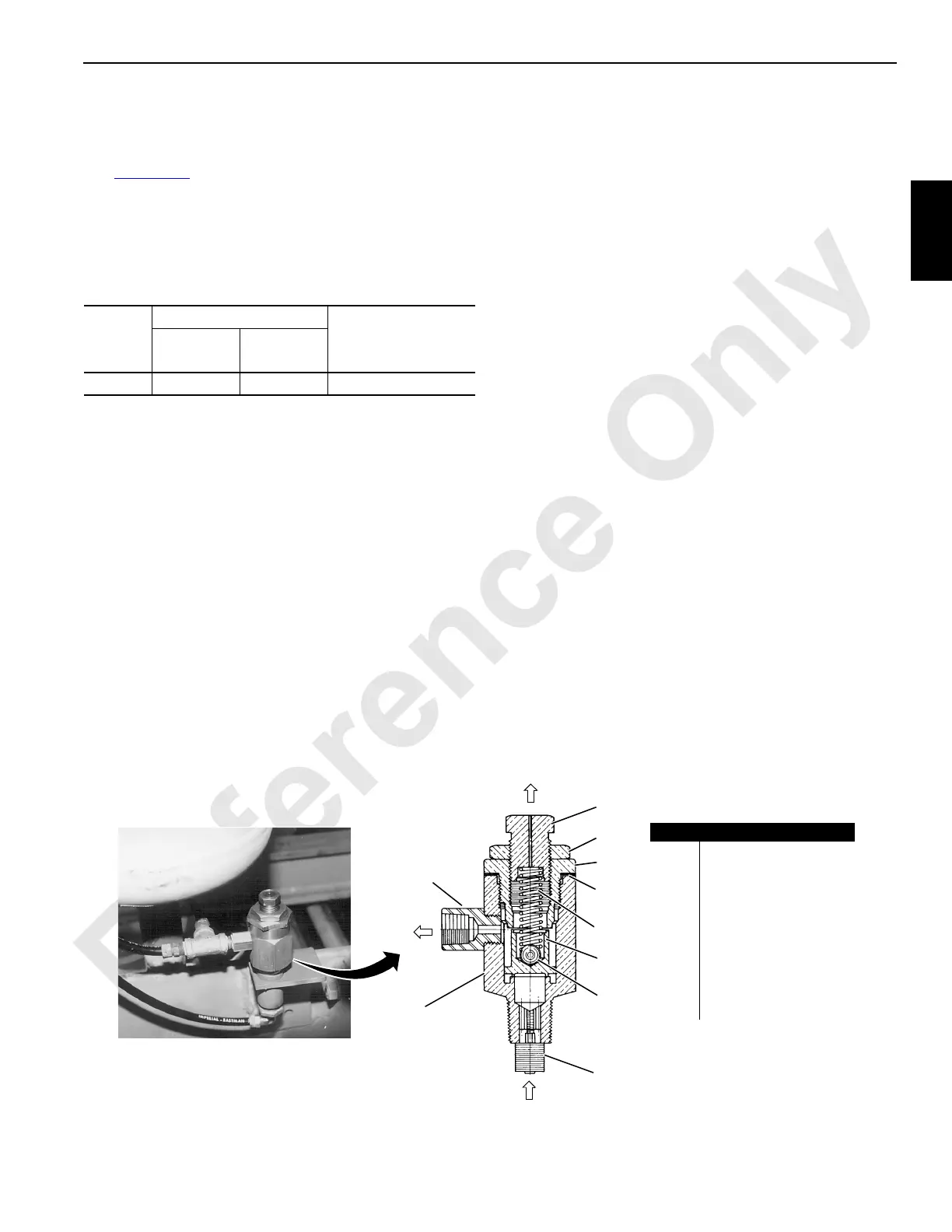

See Figure 2-28 for the following procedure.

The unloader pilot valve automatically controls air system

pressure by controlling when the compressor starts and

stops compressing air.

Table 2-13

Unloader Pilot Valve Air System Pressure Settings

Air pressure from the air tank acts against unloader valve (8)

during operation.

As air system pressure increases, unloader valve moves up

against the resistance of unloader spring (5). When air

pressure reaches the cut-out setting, the unloader valve

seats against unloader cap (4). This action closes the

exhaust port in adjusting screw (2) and opens a flow path

from the air tank to the compressor unloading mechanism.

The air compressor then stops compressing air.

When air system pressure decreases to the cut-in setting,

unloader spring (6) forces unloader valve (8) down, seating it

against unloader body (7). This action closes the flow path

from the air tank and opens the exhaust port in adjusting

screw (2). The air at the compressor unloading mechanism

then exhausts and the compressor starts compressing air.

Adjustment

The unloader pilot valve has a 12 psi (0,83 bar) range

between the cut-out and cut-in pressures. The range is fixed

and can be changed only slightly by removing or installing

shims (5). Remove one shim to increase the range or add

one shim to decrease the range.

To adjust the cut-out setting, loosen lock nut (3) and turn

adjusting screw (2) in to increase the pressure or out to

decrease the pressure. Hold the adjusting screw and

securely tighten the lock nut.

Maintenance

If the unloader pilot valve sticks or flutters, take it apart and

clean it thoroughly in non-flammable solvent. Be sure to

clean filter (10) by removing it and washing it thoroughly in

non-flammable solvent. Be sure to reinstall the filter, as it is

important that no foreign matter enters the valve chamber.

In case of unsatisfactory operation, perform the following

services:

1. Check the compressor unloading mechanism for

damage (see Air Compressor manual).

2. Disconnect the air line from the air tank at the unloader

pilot valve, and blow out all oil, sludge, scale, etc.

3. Disassemble the entire unloader pilot valve. Wash all

parts in non-flammable solvent, and reassemble.

4. In case of major repair work, it is recommended that the

unloader pilot valve be returned to the valve

manufacturer, due to the special tools and testing

equipment required to lap and align the seating

surfaces.

Model

Unloader Pilot Valve

Safety Valve

Cut-In

1

psi (bar)

1

Cut-in is pressure at which air compressor starts

compressing air.

Cut-Out

2

psi (bar)

2

Cut-out is pressure at which air compressor stops

compressing air.

2250

120 (8,3) 132 (9,1) 165 psi (11,4 bar)

Item Description

1 Unloader Outlet

2 Adjusting Screw

3 Lock Nut

4 Unloader Cap

5 Unloader Cap Shim

6 Unloader Spring

7 Unloader Body

8 Unloader Valve

9Valve Ball

10 Filter

P296

Exhaust

From

Air Tank

2

3

5

6

9

10

Typical Mounting Near

Air Tanks or Compressor

S109

To A i r

Compressor

FIGURE 2-28

1

Unloader Pilot Valve

7

8

4

Loading...

Loading...