TROUBLESHOOTING 2250 SERVICE/MAINTENANCE MANUAL

10-60

Published 11-06-15, Control # 040-13

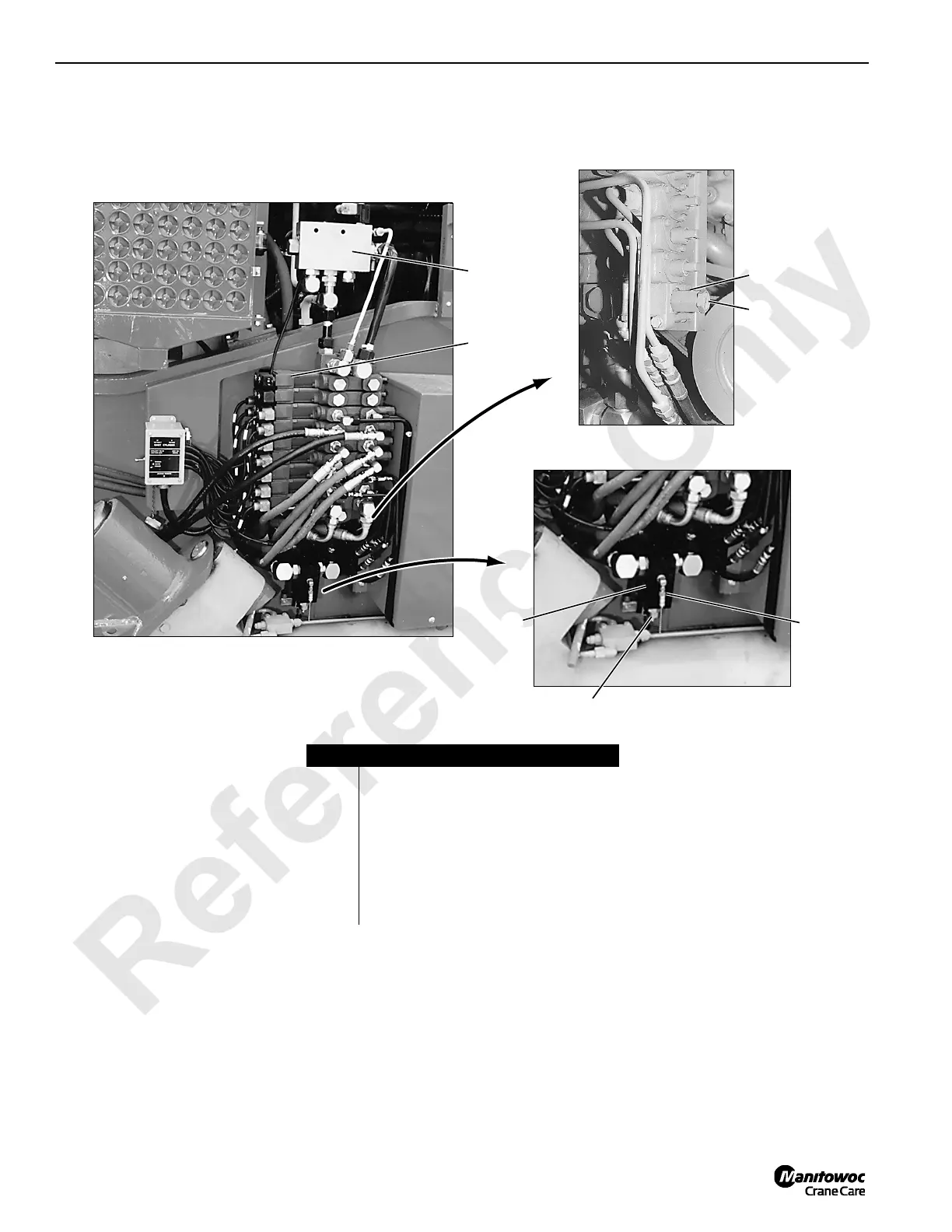

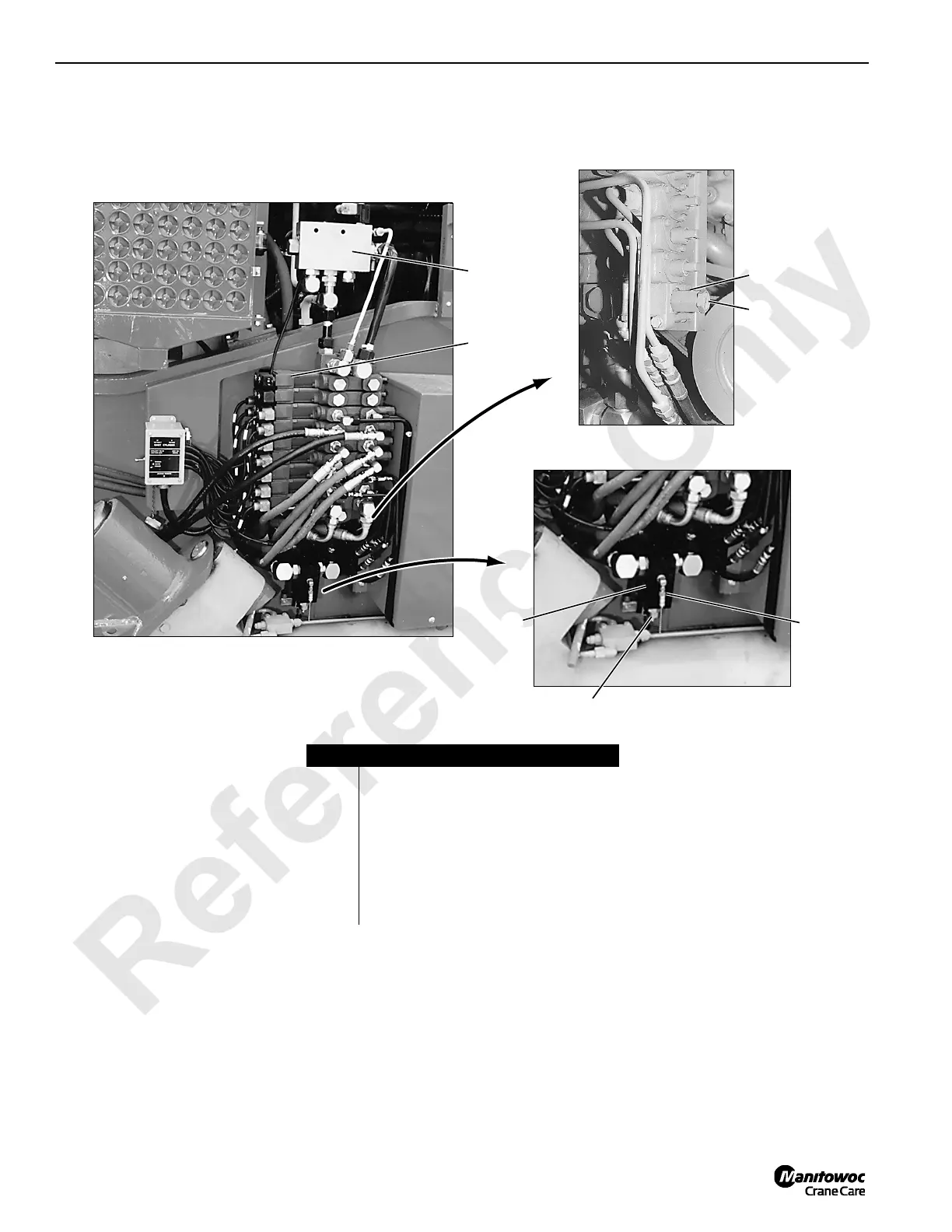

Test 25 — Checking and Adjusting Auxiliary System Working Pressure

To determine if piston actuation problems are related to

auxiliary system low-pressure, check the pressure at

auxiliary system disable valve at the upper valve assembly.

To check auxiliary system working pressure:

• Engine must be off and power off, with all brakes and

locks engaged.

• Remove the cap from diagnostic gauge coupler at

disable valve.

• Connect a 0 – 6,000 psi (0 – 413 bar) gauge to

diagnostic gauge coupler.

• Start the engine and retract any hydraulic cylinder

directly driven off upper valve assembly.

Item Description

1 Proportional flow control valve

2 Upper accessory valve assembly

3 Auxiliary system disable valve

4 Disable valve adjusting screw

5 Disable valve gauge port

6 Accessory relief valve

7 Relief valve adjusting screw

Loading...

Loading...