Manitowoc Published 11-06-15, Control # 040-13 4-5

2250 SERVICE/MAINTENANCE MANUAL BOOM

SETUP BOOM ANGLE

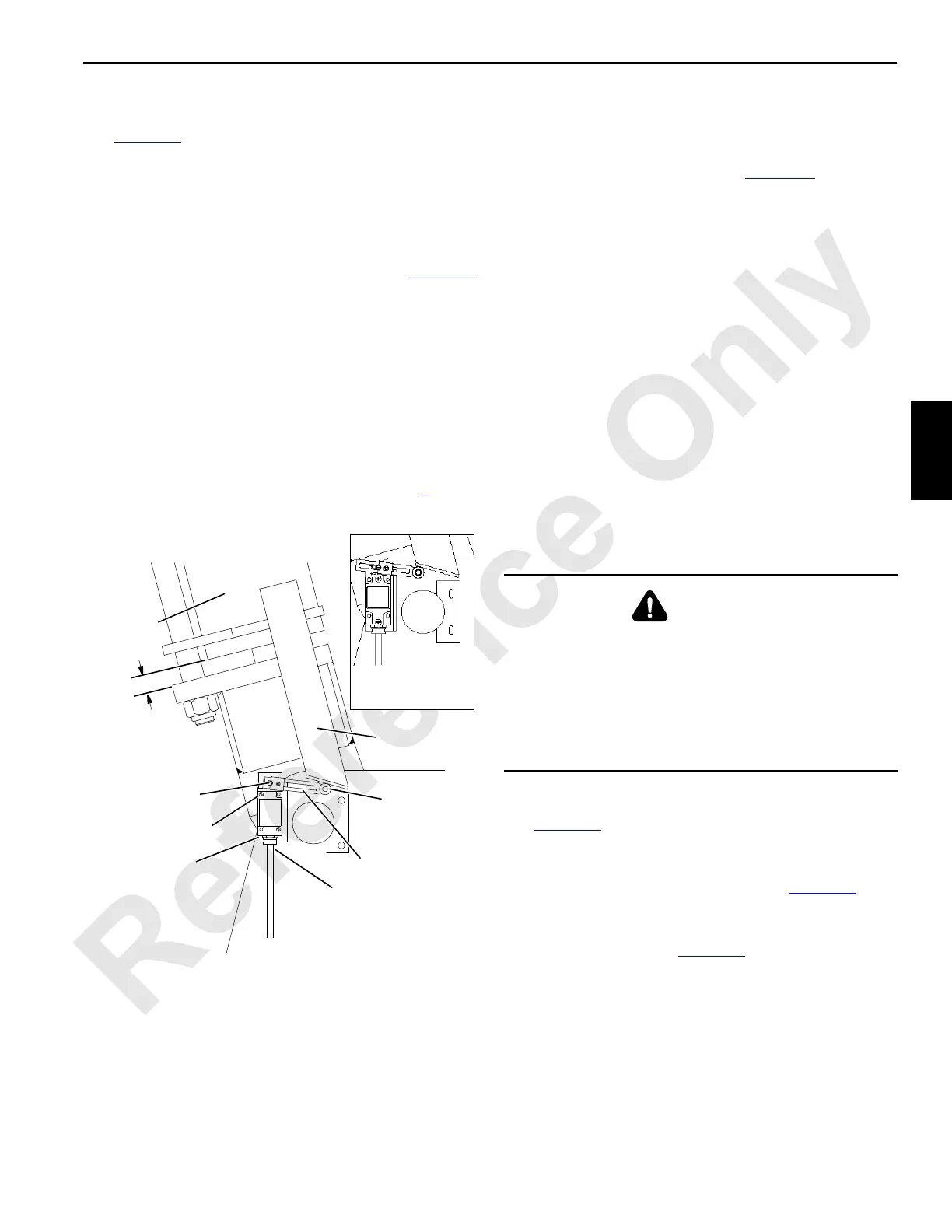

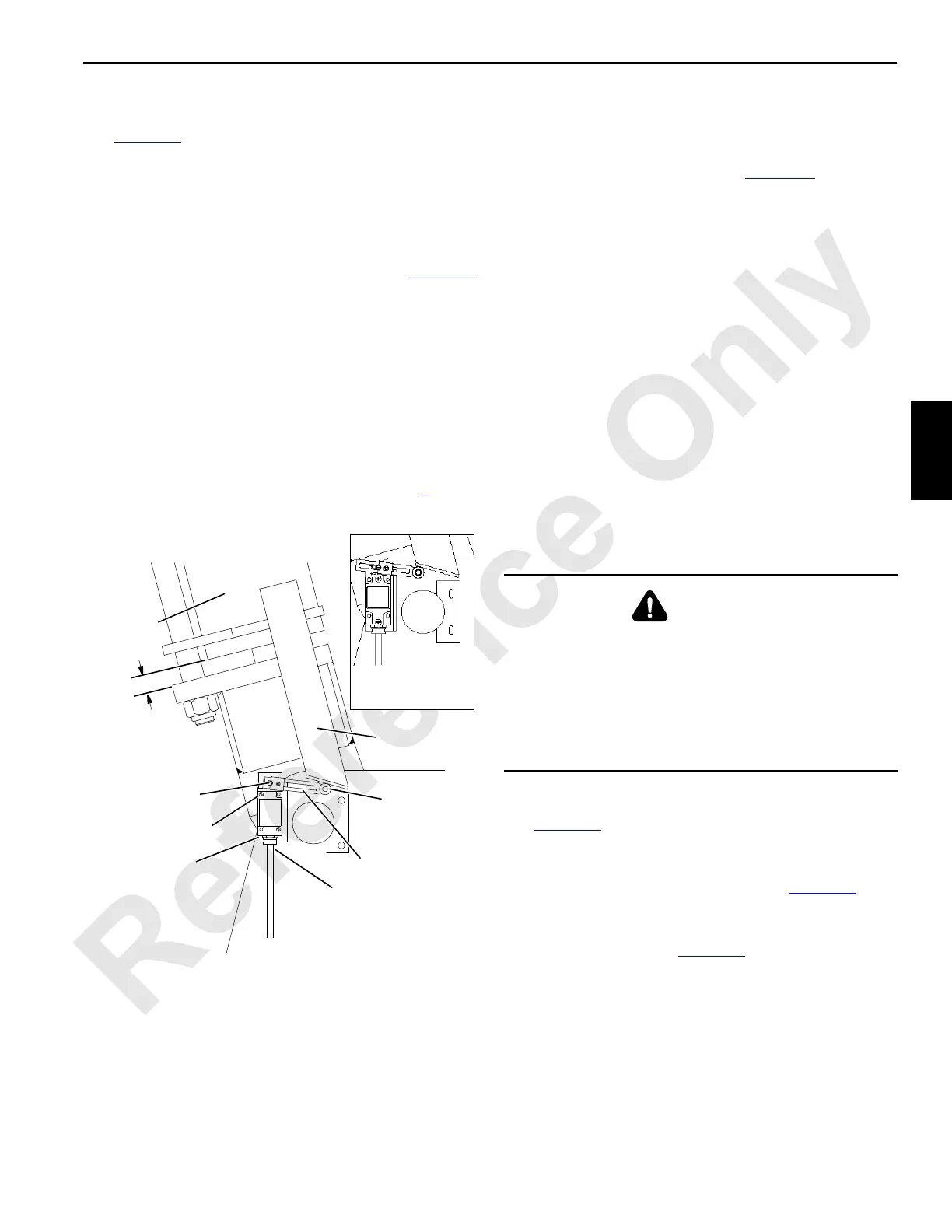

See Figure 4-4 for the following procedure.

Perform the following steps when the crane is in the setup

mode and rigged only with the boom butt.

1. Loosen setscrew in limit switch lever so lever is free to

rotate on shaft.

2. Raise boom butt until physical boom stops are 1 in (25,4

mm) from bottoming out as shown in Figure 4-4

(approximately 89° boom angle).

3. Hold roller on lever against actuator. The length of the

lever can be adjusted if a current production limit switch.

4. Turn limit switch shaft CLOCKWISE (viewing switch)

until switch clicks open and hold.

5. Securely tighten setscrew in lever.

6. Lower boom butt several degrees.

7. Slowly raise boom butt.

8. Boom butt must stop at point specified in step 2

. If not,

repeat Setup Boom Angle Adjustment steps.

PHYSICAL BOOM STOP

General

The physical boom stop assembly (Figure 4-5) serves the

following functions:

• Assist in stopping the boom smoothly at any angle

above 80

°.

• Assist in preventing the boom rigging from pulling the

boom back when traveling or setting loads with the

boom at any angle above 80

°.

• Assist in moving the boom forward when lowering the

boom from any angle above 80

°.

• Provide a physical stop at 90

°.

The strut cylinders between the boom stop tubes and the

boom butt have two positions:

• WORKING POSITION (struts fully extended) — The

physical boom stop must be in this position for all crane

operations.

• SHIPPING POSITION (struts fully retracted) — This

position provides maximum clearance for shipping the

boom butt with the physical boom stop installed.

Operation

See Figure 4-5 for the following procedure.

1. Air system pressure of 125 to 137 psi (8,6 to 9,4 bar) is

trapped in boom stop cylinders by a check valve

connected to each cylinder’s inlet port (Figure 4-5

, View

A).

2. When boom is raised to 80

°, boom stop rod ends contact

pins in adapter frame (Figure 4-5

, View B).

3. Cylinder rods then start to compress air trapped in boom

stop cylinders by check valves.

4. As boom is raised higher, pressure of trapped air

increases to exert greater force against boom.

5. If for any reason boom is raised to 90

°, boom stop

cylinders will fully compress air and bottom out to

provide a physical stop.

FIGURE 4-4

A513

Left Side

Physical

Boom Stop

Actuator

Roller

Lever

NOTE: Standard mounting shown. Mounting is raised

approximately 2 ft (0,61 m) when equipped with fold-

under luffing jib.

To A i r Va lv e

Junction Box

Connect electric wires to

normally closed contacts

(1 and 2) inside limit

switch

Past Production

Setup Limit Switch

Setscrew

Shaft

1 in

(25,4 mm)

NOTE: Past Production limit switch has fixed arm.

Current Production limit switch has adjustable arm.

Current Production

Adj. Limit Switch

192115_3

WARNING

Boom Hazard!

Physical boom stop must be installed for all crane

operations.

Physical boom stop does not automatically stop boom at

maximum operating angle. Automatic boom stop must be

installed and properly adjusted (see Automatic Boom Stop

topic in this section).

Loading...

Loading...