Manitowoc Published 11-06-15, Control # 040-13 2-29

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

established, the de-icer will automatically adjust the drip rate

proportionally to variations in the air flow. Push green lock

ring downward to lock setting after final adjustment. To

release, pull lock ring upward.

Maintenance

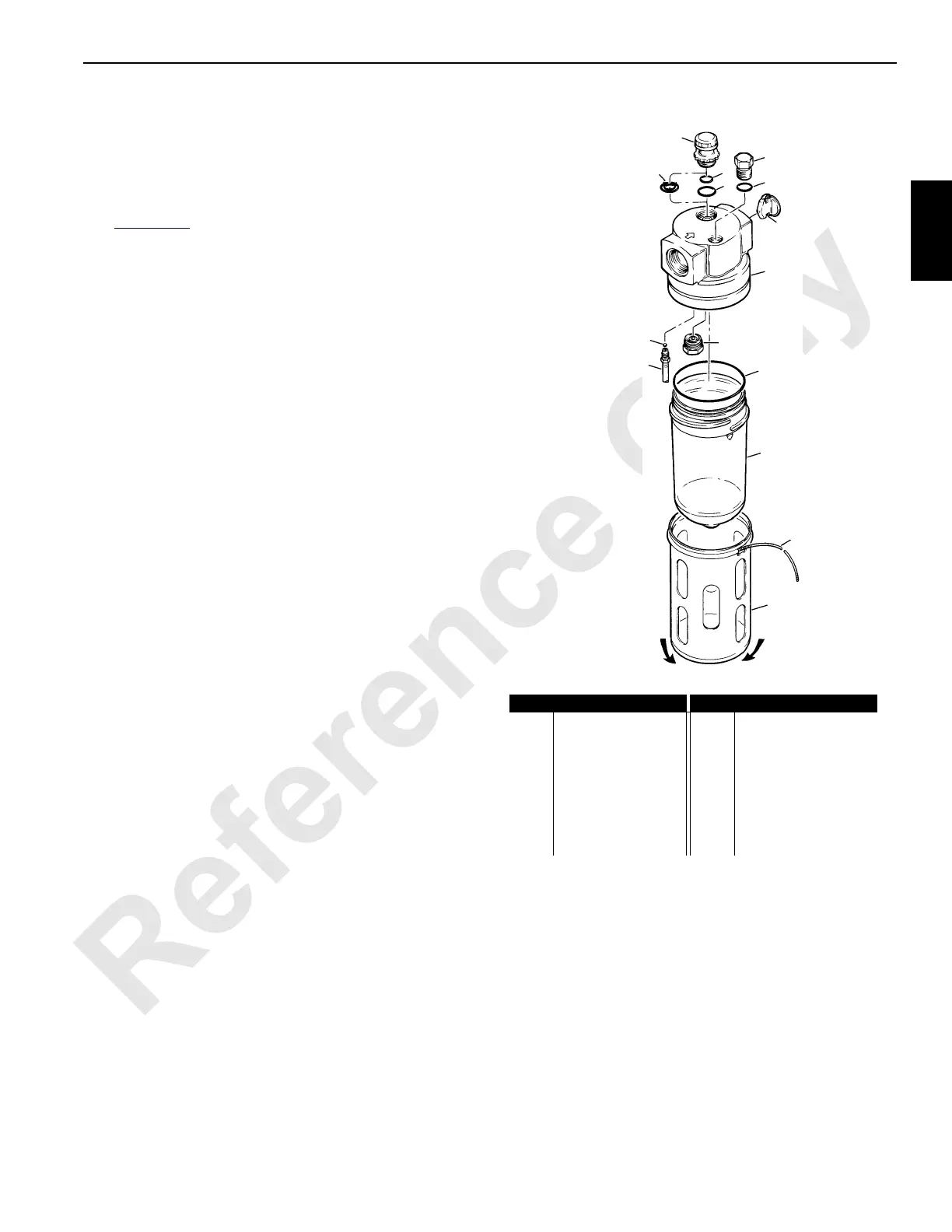

See Figure 2-33 for the following procedure.

To service the de-icer, shut off the air pressure. De-icer may

be disassembled without removal from air line.

If de-icer has transparent reservoir, remove guard (15) by

rotating guard around body (13) to wind out retaining spring

(14) through cutout in guard. Slide guard off body.

Unscrew and remove reservoir (9). Remove o-ring (3), fill

plug (4) and o-rings, (10 and 11) or seal (12), charge valve

(2), if used, siphon tube assembly (6) and check ball (8).

Flow sensor (1) should not be removed unless obviously

damaged. If removal is necessary, insert needle nose pliers

into inlet port in body (13) and grasp point of flow sensor.

Turn sensor approximately 1/4-turn either direction and push

out through outlet port of body.

Clean transparent reservoir using clear, warm water only.

Clean other pars using soap and water. Dry parts and blow

out internal passages using clean, dry compressed air.

Inspect each part carefully. Replace any parts which are

damaged.

At reassembly, make sure to reinstall flow sensor (1), if

removed, with point in direction opposite to flow arrow on

body (13). Apply a wipe coat of 44M grease (or equivalent) to

O-ring (3). Torque dome assembly (7) and charge valve (2),

if used, to 30 to 35 in/lb (3,4 to 4,4 N•m). Tighten siphon tube

(6) until snug only. Tighten reservoir (9) by hand until

arrowhead on reservoir is in line with or to the right of

arrowhead on body. Slide guard (15) onto body and align

retaining spring bead in guard with groove in body. Start

retaining spring (14) into groove through cutout in guard.

Rotate guard around body to 'wind in' the spring.

Filling

Fill reservoir with a good quality desiccant to level indicated

by maximum fill line. Do not overfill.

S116

Install

Remove

FIGURE 2-33

Item Description Item Description

1 Flow Sensor 9 Reservoir

2 Check Valve (charge) 10 O-Ring

3 O-Ring 11 O-Ring

4 Fill Plug 12 Seal

5O-Ring 13Body

6 Siphon Tube 14 Retaining Spring

7 Sight Feed Dome 15 Side Guard

8 Check Ball

6

8

2

9

5

7

1

3

4

14

12

15

13

10

11

Loading...

Loading...