INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-78

Published 11-06-15, Control # 040-13

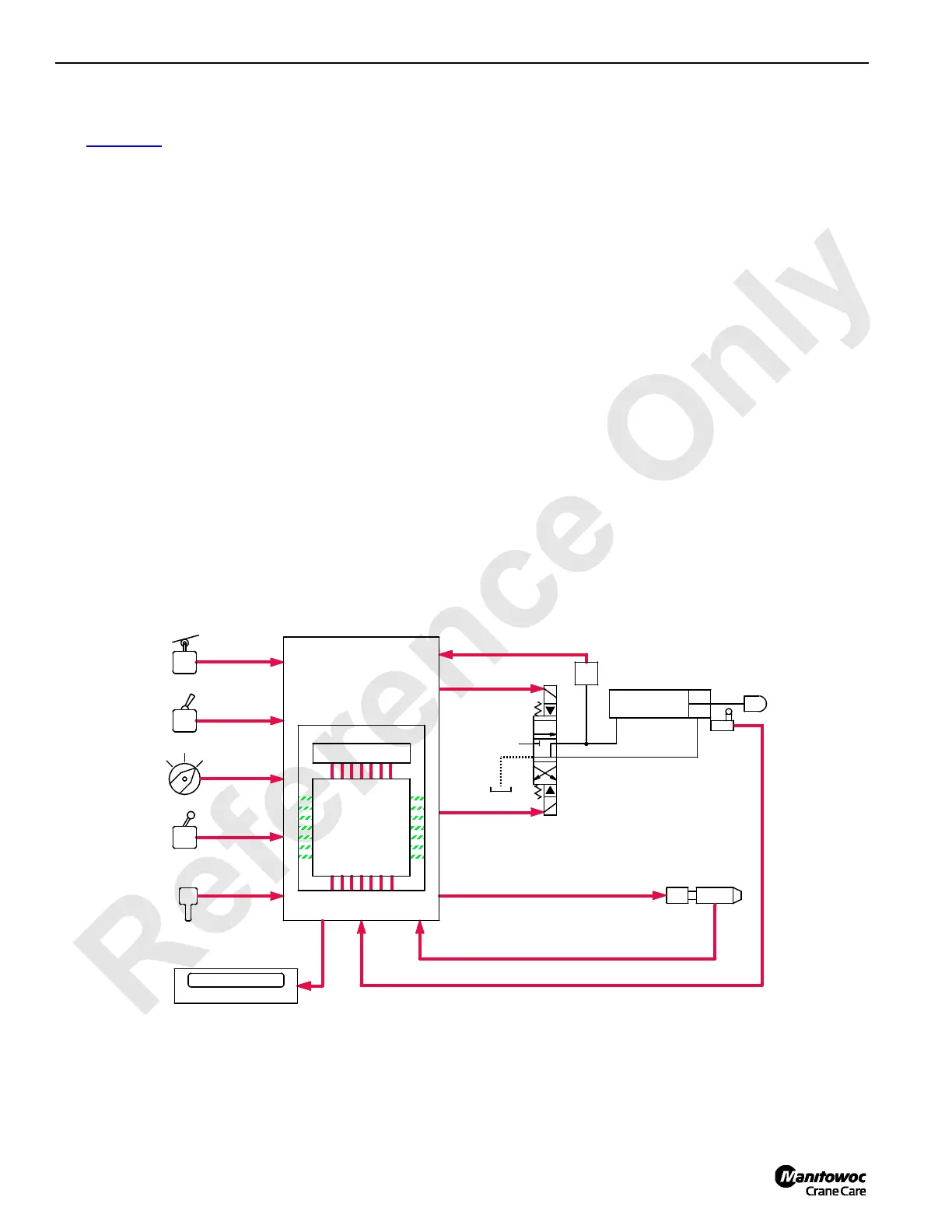

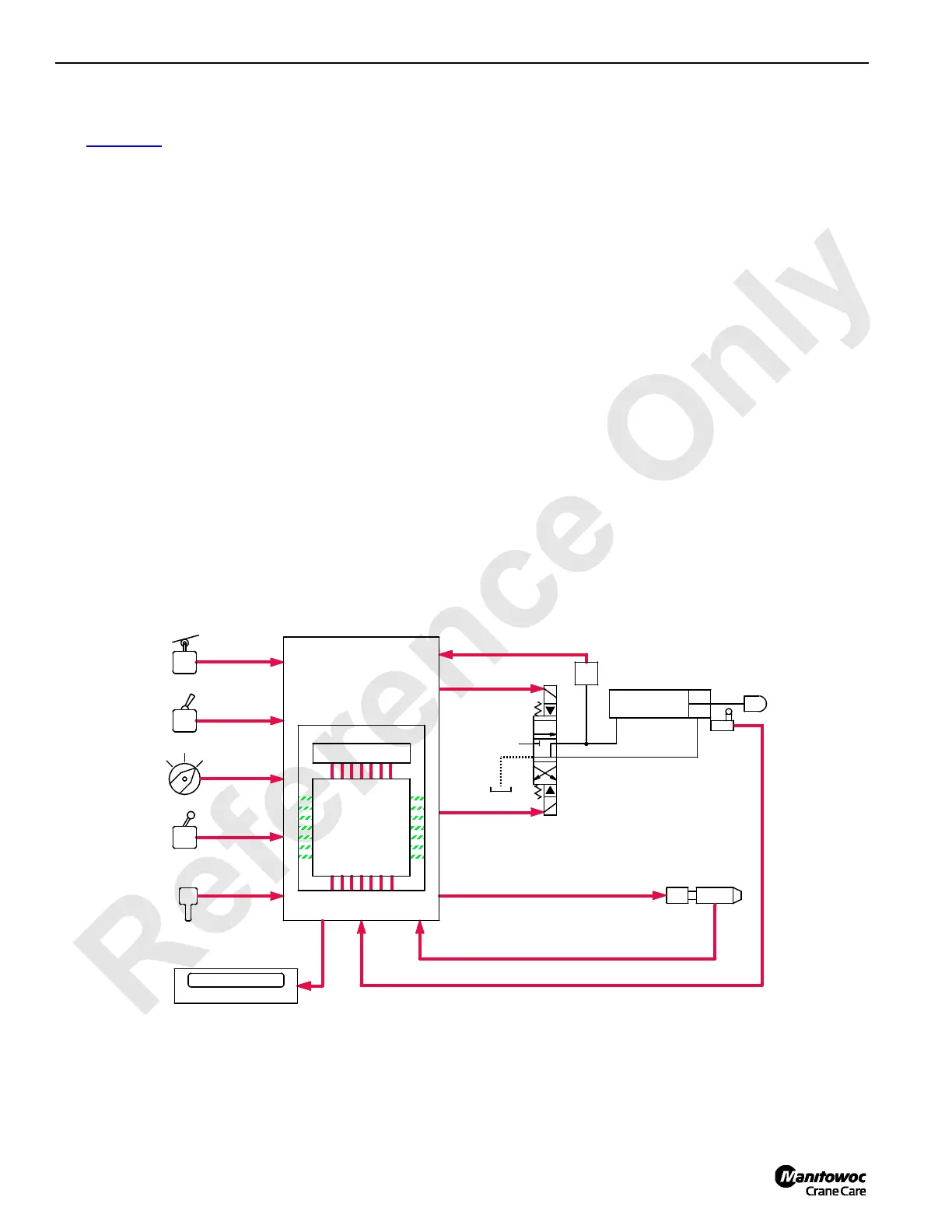

EPIC

®

Programmable Controller

See Figure 1-47 for the following procedure.

The MAX-ER’s solenoid valves, cylinders, and motors are

monitored and controlled with electronic components of the

EPIC (Electrical Processed Independent Control) system.

The crane PC (Programmable Controller) and MAX-ER PC

are interfaced with serial wire RX3 (36) and TX3 (37). In this

section, the abbreviation (PC) assumes MAX-ER

Programmable Controller unless noted otherwise.

The PC receives and sends both analog and digital input/

output signals. Analog input/output signals are AC or DC

voltages or currents that are modulating. Digital input/output

signals are 12 volt nominal voltages that are either on or off.

The PC uses the binary system. The binary system is based

on multiples of 2, and only recognizes 0 for off or 1 for on

voltages. Basic counts of this system are exponents of the

number 2. These exponents are formed in words, called

bytes, of eight numbers each. The eight numbers are 1, 2, 4,

8, 16, 32, 64, and 128 for an 8-bit controller or a combination

of up to 255 bytes. These bytes represent electrical inputs to

the controller. The controller processes this information by

comparing it to programming requirements and data

information. The PC then provides appropriate output

commands to control devices.

Operating controls or control handles send input voltage

command signals to the MAX-ER or crane PC. The PC

compares these input voltages with feedback voltages

received from system monitoring sensors, memory

information, and directives entered into programming.

Monitoring sensors includes; limit switches, pressure

senders, encoders, counterweight level sensor, and back

hitch load pin sensor. The PC then sends a 12-volt output

signal to solenoid valves to control system cylinders, brakes,

pawls, and other controls.

NOTE: Rated Capacity Indicator/Limiter (RCL) system has

its own programmable controller and is part of the

EPIC system. For complete information see

separate Rated Capacity Indicator/Limiter

Operation manual.

Luffing jib (drum 5) operates the same as a load drum,

whether used as whip line or luffing jib. For drum 9 operation,

load drum holding pressure memory is used. Before

releasing drum disc brake, the PC reverses voltage polarity

to crawler travel (or main hoist in MAX-ER mode) pump

EDC’s, stroking crawler travel pumps in the up direction until

pressure memory is met. The PC then responds to left

control handle (drum 9) commands. See Operating Controls

topic in Section 3 of the MAX-ER Operator Manual for

description of drum numbers and handle indicator lights.

RM-01

SENSOR VOLTAGE INPUT

DIGITAL DISPLAY

MONITORING

VOLTAGES OUT

MEMORY

VOLTAGES

TO

COUNTS

TO

VOLTAGES

COMMAND

VOLTAGES IN

SENSOR DIGITAL INPUT

PROGRAMMABLE

CONTROLLER - PC

PROCESSING

CONTROL

HANDLES

SELECTORS

SWITCHES

LIMIT

SWITCH

REMOTE

CONTROL

P

HYDRAULIC

SOLENOID

HYDRAULIC

CYLINDER

LIMIT

SWITCH

PRESSURE

SENDER

T

VOLTAGE OUT

VOLTAGE OUT

VOLTAGE OUT

RIGHT SIDE CRANE

TYPICAL

BACKHITCH LOAD PIN

FIGURE 1-47

Loading...

Loading...