Manitowoc Published 11-06-15, Control # 040-13 2-17

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

Initial Oil Fill

NOTE: Use proper viscosity new hydraulic oil filtered

through at least a 10-micron filter.

1. Fill each motor case with clean oil to level of case drain

port (Figure 2-18

).

2. Fill pump cases as follows:

a. Remove pipe plug from case drain pipe

(Figure 2-19

).

b. Slowly fill pipe with clean oil. Air will gurgle out of

pipe as oil is added.

c. Stop filling pipe when oil stops gurgling and pipe is

full.

d. Securely install pipe plug.

3. Fill hydraulic tank with clean oil to middle of FULL level

sight gauge (Figure 2-20

).

Pressure Sender Calibration

Perform this procedure before Initial Start-Up.

1. Turn on cab power switch.

2. Turn crane mode selector key counterclockwise to

confirm position and hold.

3. Press engine run/stop switch to run position.

4. Continue to hold crane mode selector key in confirm

position for one minute after performing 3

.

5. Confirm for proper calibration — with engine off (key in

run), charge pressure on diagnostic screen for each

crane function should be 50 psi (3,4 bar) or less.

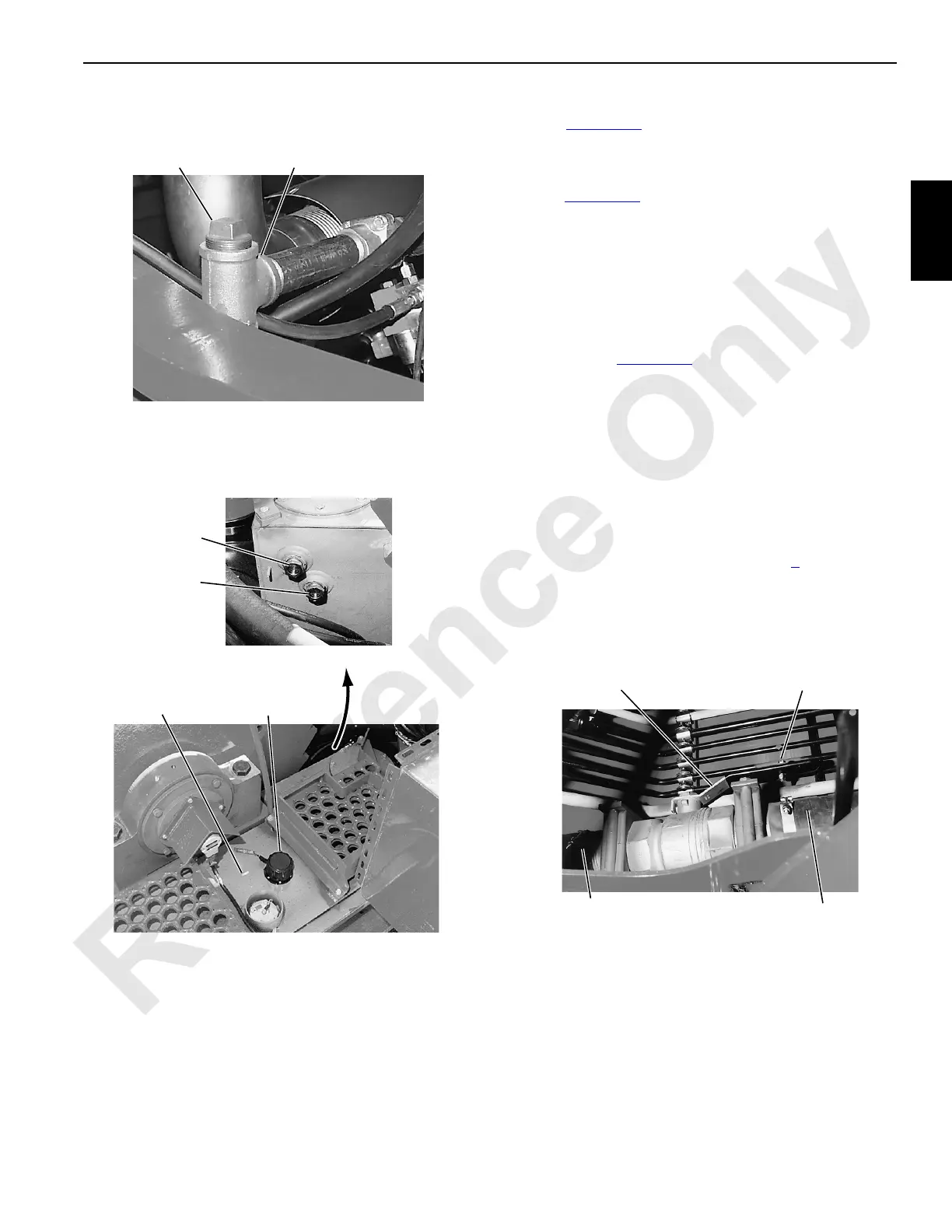

FIGURE 2-19

Access at Left Rear Side of Rotating Bed

(to rear of pumps)

Pipe

Plug

P969

Case Drain

Return Pipe

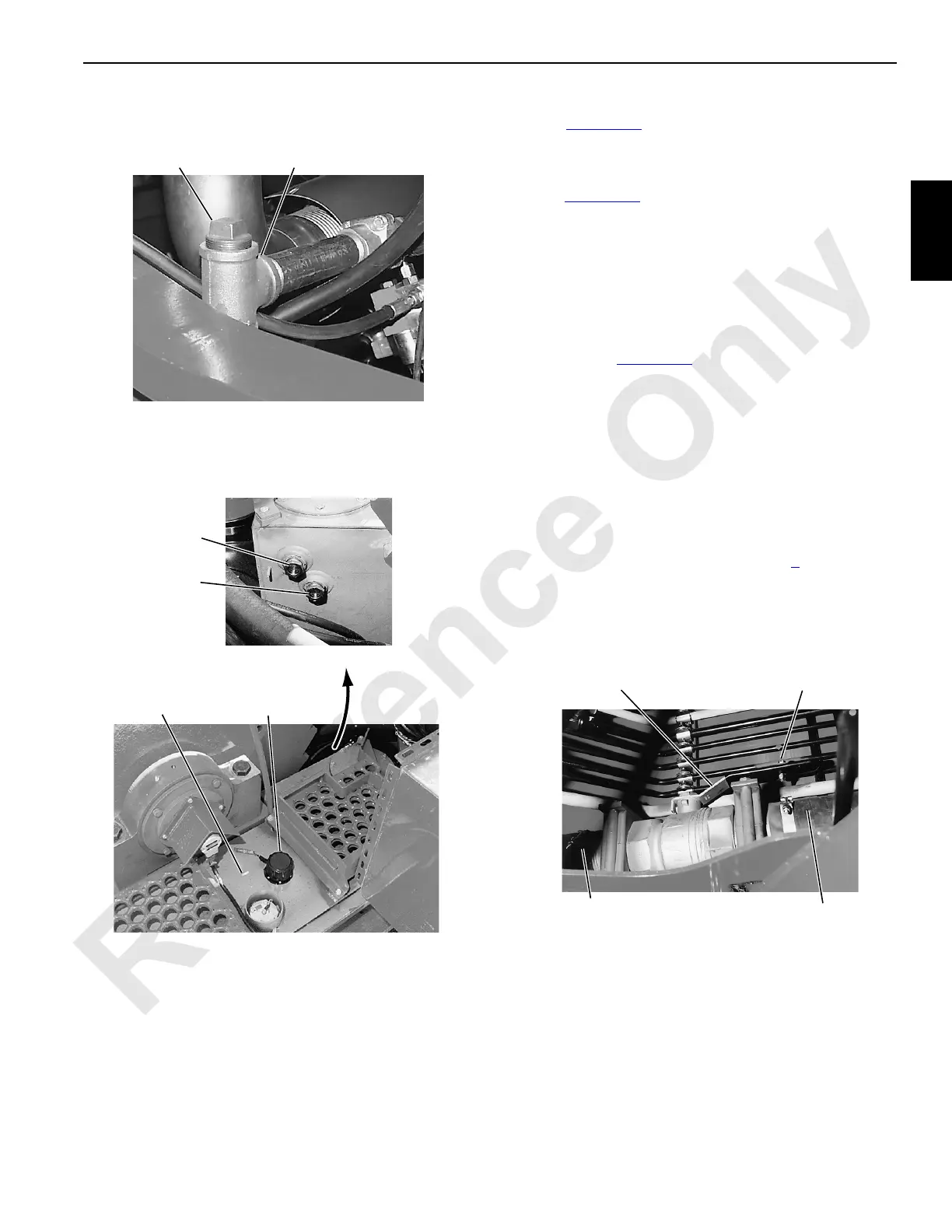

FIGURE 2-20

Hydraulic

Tank

P600

P593

Fill Cap

Access at Right Outboard Side of Rotating Bed

(next to boom hoist)

HIGH Level

Sight Gauge

LOW Level

Sight Gauge

Inboard Side of Tank

FIGURE 2-21

To Hydraulic Tank

P779

Handle OPEN

(pull toward you to close)

Install Bolt and Nut or Padlock To

LOCK handle Open

To P u mp s

Access at Rear Inboard Side of Rotating Bed

(above fuel tank)

Loading...

Loading...