HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-18

Published 11-06-15, Control # 040-13

Initial Start-Up

The following procedure requires two people: one to start

engine and monitor pressures on diagnostic screens and

one to monitor bleed lines and close bleed valves.

1. Calibrate pressure senders as described in above topic.

2. Open shut-off valve in pump suction line (Figure 2-21

).

Pumps can be damaged from cavitation if this step

is not performed.

3. Connect bleed lines equipped with shut-off valves to

gauge coupler at each pressure sender (Figure 2-16

).

4. Open shut-off valve in each bleed line. Use a suitable

container to catch oil.

5. Remove adjusting screw from fan and pilot pressure

relief valves (Figure 2-22

and Figure 2-23). Then

reinstall screws approximately 1/4 in (6 mm) and

securely tighten lock nuts. Serious damage can occur to

system components if this step is not performed before

starting engine first time.

6. With all controls off, start and run engine at lowest

possible speed.

7. Have one person bleed pressure senders while a

second person checks pressures.

8. Bleed pressure senders:

a. Observe oil flowing from bleed line at each pressure

sender (Figure 2-16

).

b. Close each bleed valve when a clear, steady stream

of oil appears (no air bubbles in oil).

c. If oil does not flow from any bleed line, determine

cause and correct.

9. On diagnostic screens, check pump pressures for load

drums, boom hoist, swing, and travel pumps:

a. Make sure pressure reading for each pump is 200 –

500 psi (13.8 – 34,5 bar). Pump pressures will be

adjusted to final setting later in this procedure.

b. If pump pressures are not within specified range,

stop engine immediately. Determine cause of

faulty pressure and correct.

10. Stop the engine.

11. Remove bleed lines from gauge couplers at each

pressure sender.

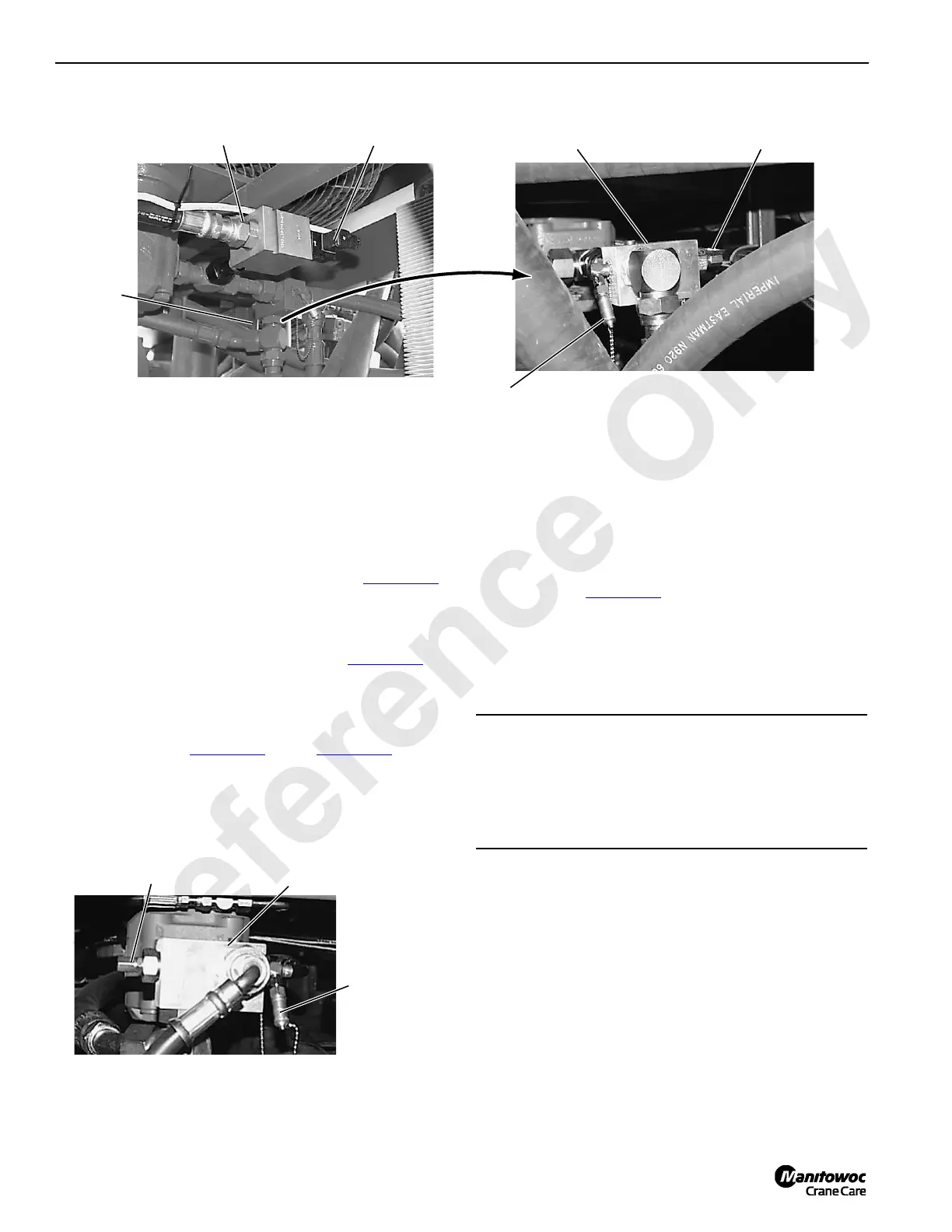

FIGURE 2-22

Fan Bypass Valve (optional)

P970

P971

Electric Plug

Fan Relief

Valve

Adjusting Screw

(with lock nut and protective cap)

Fan Relief Valve

1/8 inch Gauge Coupler

(with protective cap)

Access at Left End of Radiator

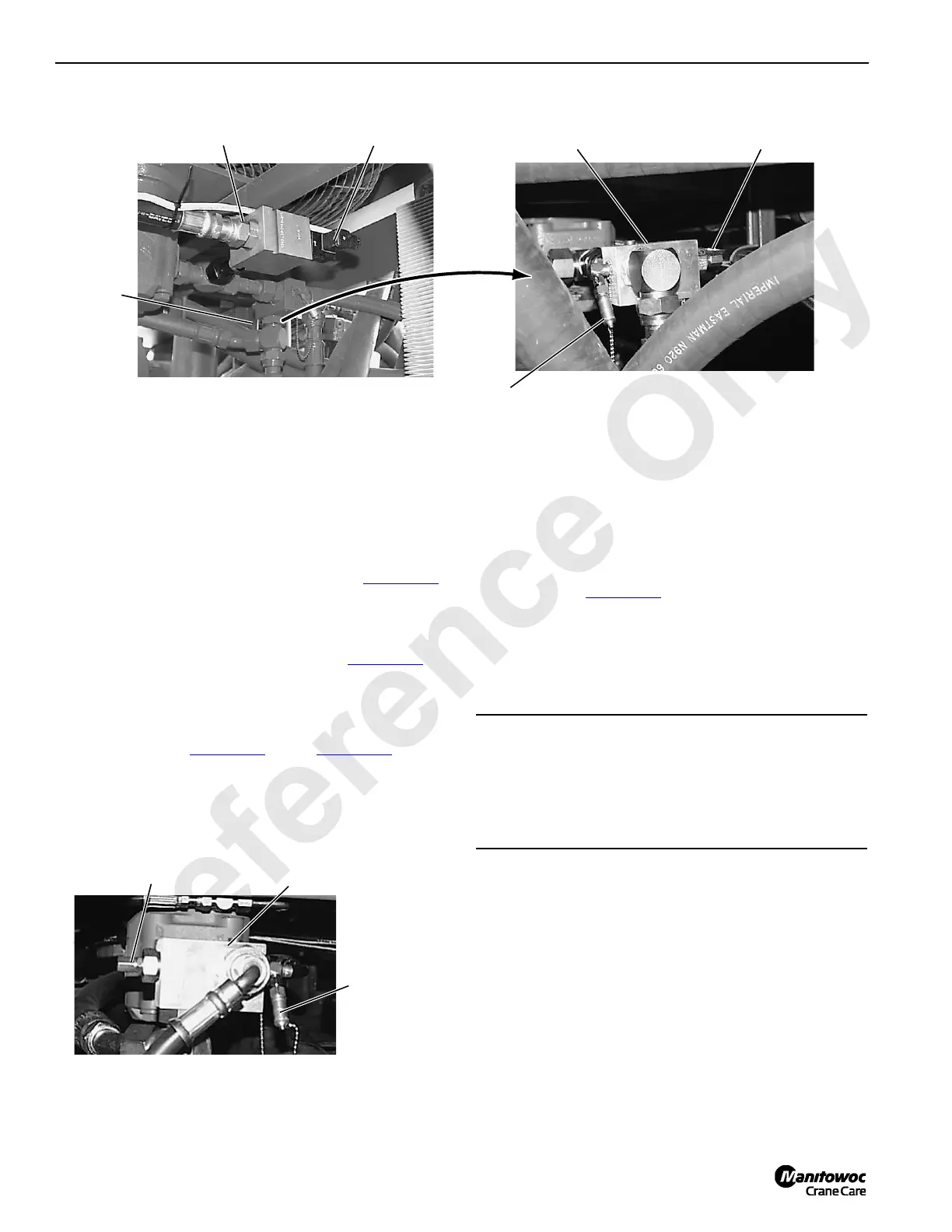

FIGURE 2-23

Adjusting Screw (with lock

nut and protective cap)

P972

1/8 in. Gauge

Coupler (with

protective cap)

Access at Right End of Radiator

Pilot Pressure

relief Valve

CAUTION

Equipment Damage!

Check pump pressure during first two minutes of

operation. If pressure for any pump is not within specified

range, shut down engine immediately to prevent pump

damage. Troubleshoot to determine cause of problem.

Loading...

Loading...