UNDER CARRIAGE 2250 SERVICE/MAINTENANCE MANUAL

8-2

Published 11-06-15, Control # 040-13

CRAWLER ADJUSTMENT

Maintenance

Crawler wear cannot be eliminated, but the rate of wear can

be reduced through regular preventive maintenance, as

follows:

• Lubricate crawlers as instructed in Lubrication, Section 9

of this manual.

• Keep crawlers clean and avoid dirt build-up when

cutting.

• Keep all mounting bolts tight (see Parts Manual for

applicable torque values).

• Keep treads properly adjusted.

• Inspect crawler gear cases, crawler frames, rollers,

treads, and drive shafts on a regular basis.

Look for oil leaks, excessive wear, cracks, and other

damage. Broken or cracked parts can indicate that the

treads are adjusted too tight.

Repair or replace damaged parts immediately to prevent

further damage.

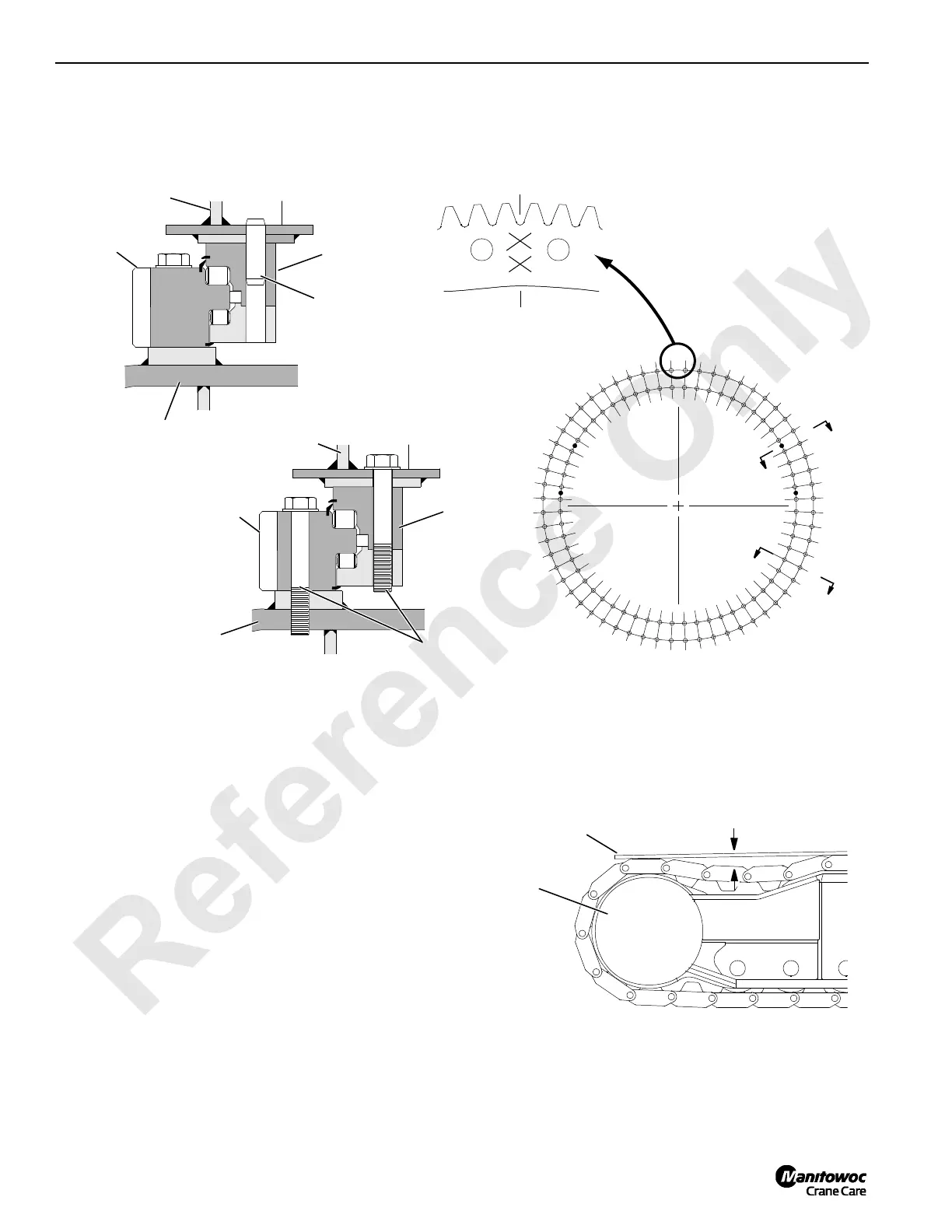

FIGURE 8-1

59

1

23

51

11

43

19

35

7

55

27

47

15

39

31

58

22

50

10

42

18

34

54

26

46

14

38

30

60

24

52

12

44

20

36

8

56

28

48

16

40

32

57

21

49

9

41

17

33

53

25

45

13

37

29

6

5

4

3

2

A473

Longitudinal Centerline at

Front or Rear of

Carbody or Carrier

Upper

Adapter

Outer

Ring

Inner

Ring

Dowel Pin

(4 each)

View A-A

Upper

Adapter

View B-B

Outer

Ring

Carbody, Carrier,

or Turret

Inner

Ring

Bolts with Hardened

Washers (60 each ring)

B

B

A

A

Carbody, Carrier,

or Turret

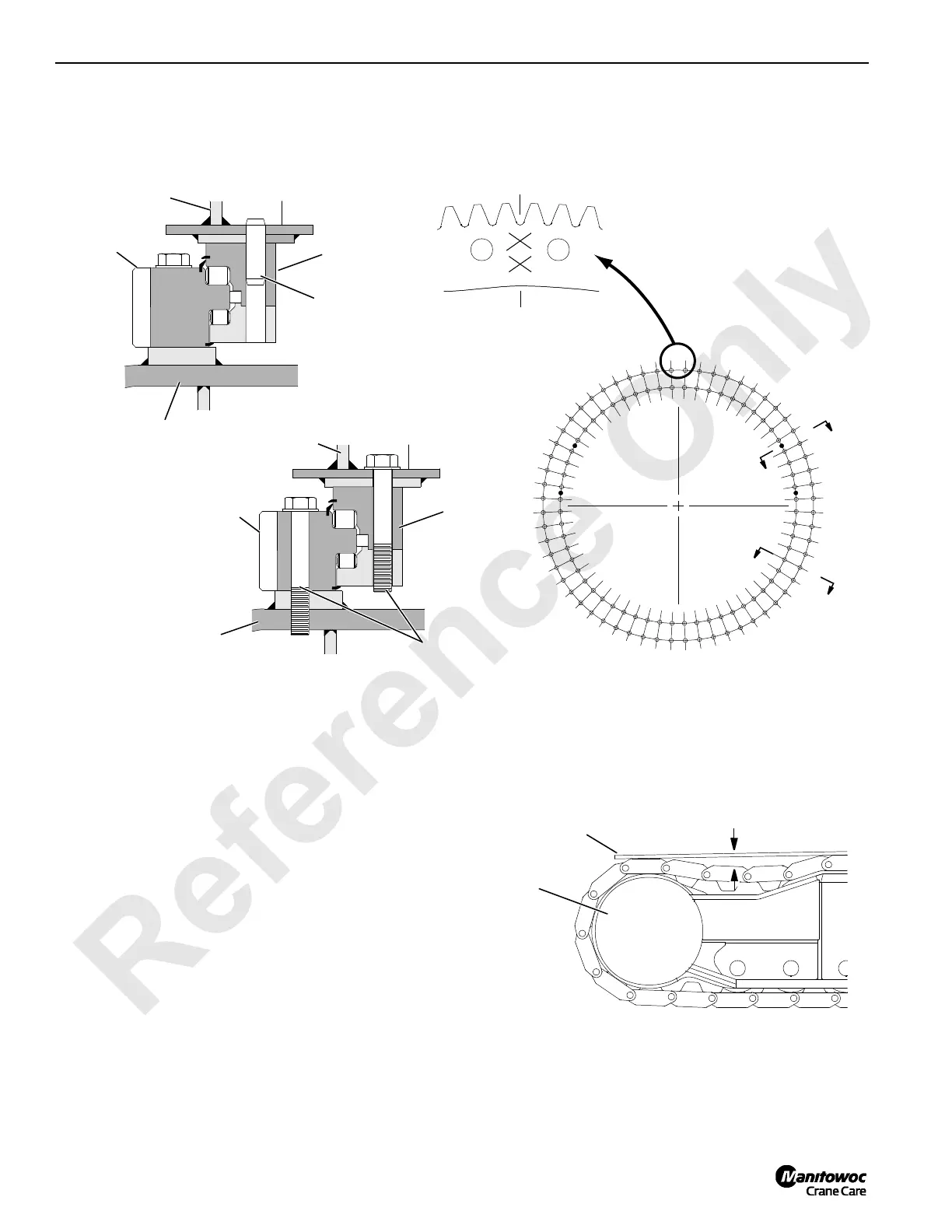

FIGURE 8-2

A1052

Straight

Edge

1 in (25 mm) Tight Limit

2-1/2 in (63 mm) Loose Limit

Gap

Crawler

Tumbler

Loading...

Loading...