Manitowoc Published 11-06-15, Control # 040-13 2-43

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

Adjustment

1. Shut down the crane.

2. Discharge system air pressure.

3. Disconnect crane source air line piping at pressure

switch that needs adjustment.

4. Remove cover screw (4) and cover.

5. Connect a calibrated pressure source with gauge to the

1/4” NPT fitting on the air sensor inlet ensuring there are

no air leaks.

6. Connect one lead of the tester to either the N.C. terminal

or the N.O. terminal of the limit switch, depending on the

circuit application. Ground the other lead of the tester.

7. Connect the D.C. voltage power supply to the COM

(common) terminal of the limit switch.

8. If the pressure switch is wired normally closed,

proceed as follows:

a. Turn the adjusting screw all the way in and then out

until it just touches the plunger.

b. Increase air pressure to the specified point (tester

light should go OFF).

c. Turn the adjusting screw IN until the tester light

comes ON.

9. If the pressure switch is wired normally open, proceed

as follows:

a. Turn the adjusting screw all the way in.

b. Increase air pressure to the specified point.

c. Turn the adjusting screw OUT until the tester light

comes ON.

10. Always recheck set points after adjustments are made.

11. Disconnect the D.C. voltage power supply, calibrated air

supply, and tester.

12. Reinstall air pressure switch.

13. Start crane and allowing system to reach operating

pressure. Activate corresponding circuit to test and

confirm pressure switch trip point.

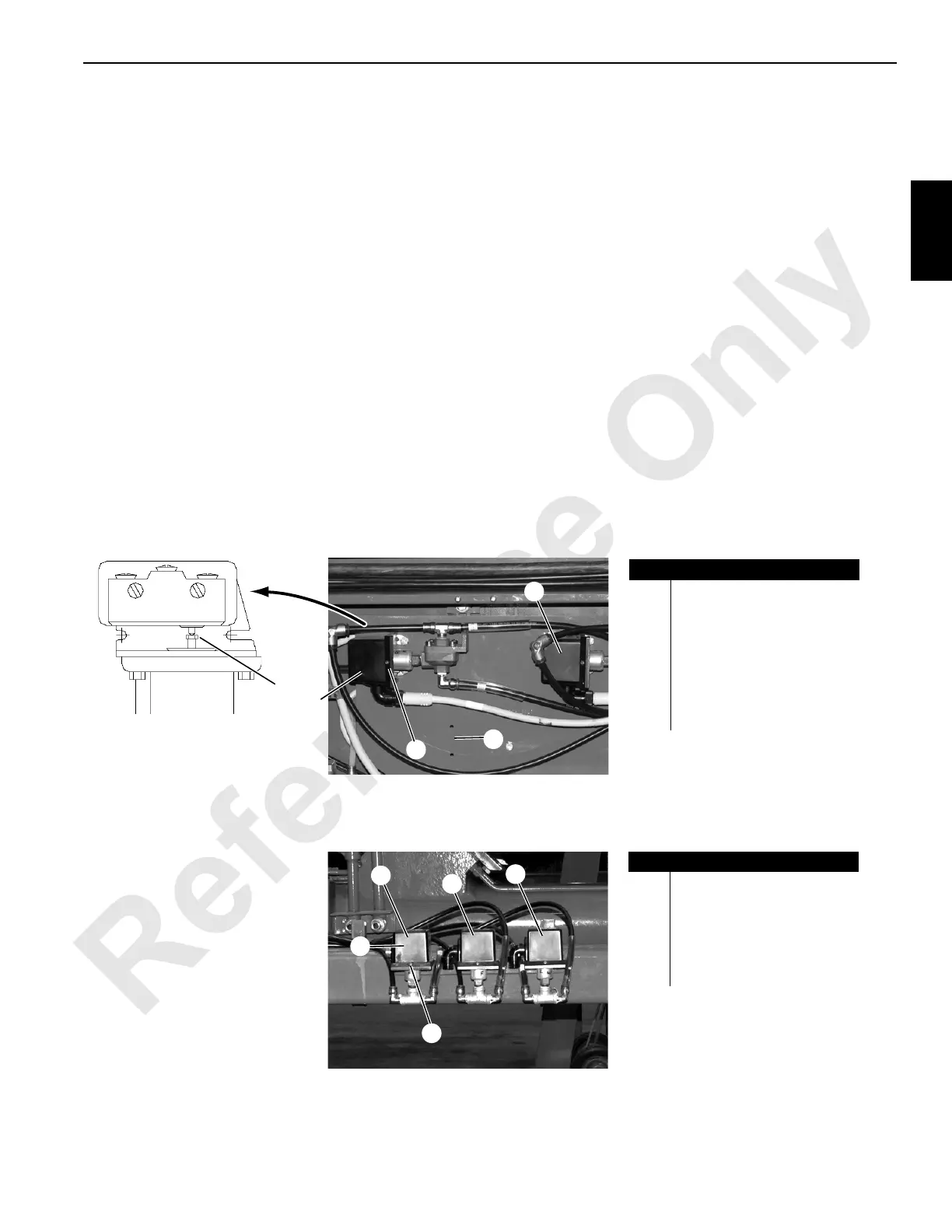

P2487_1

673356

Item

Description

1

Drum 3 (Left Rear)

Pressure Switch

2

Drum 2 (Rear/Right Rear)

Pressure Switch

3

Drum 1 (Front) Pressure

Switch (not shown)

4 Cover Screw (typical)

5 Switch Adjustment Screw

5

Left Side of Crane

1

2

FIGURE 2-43

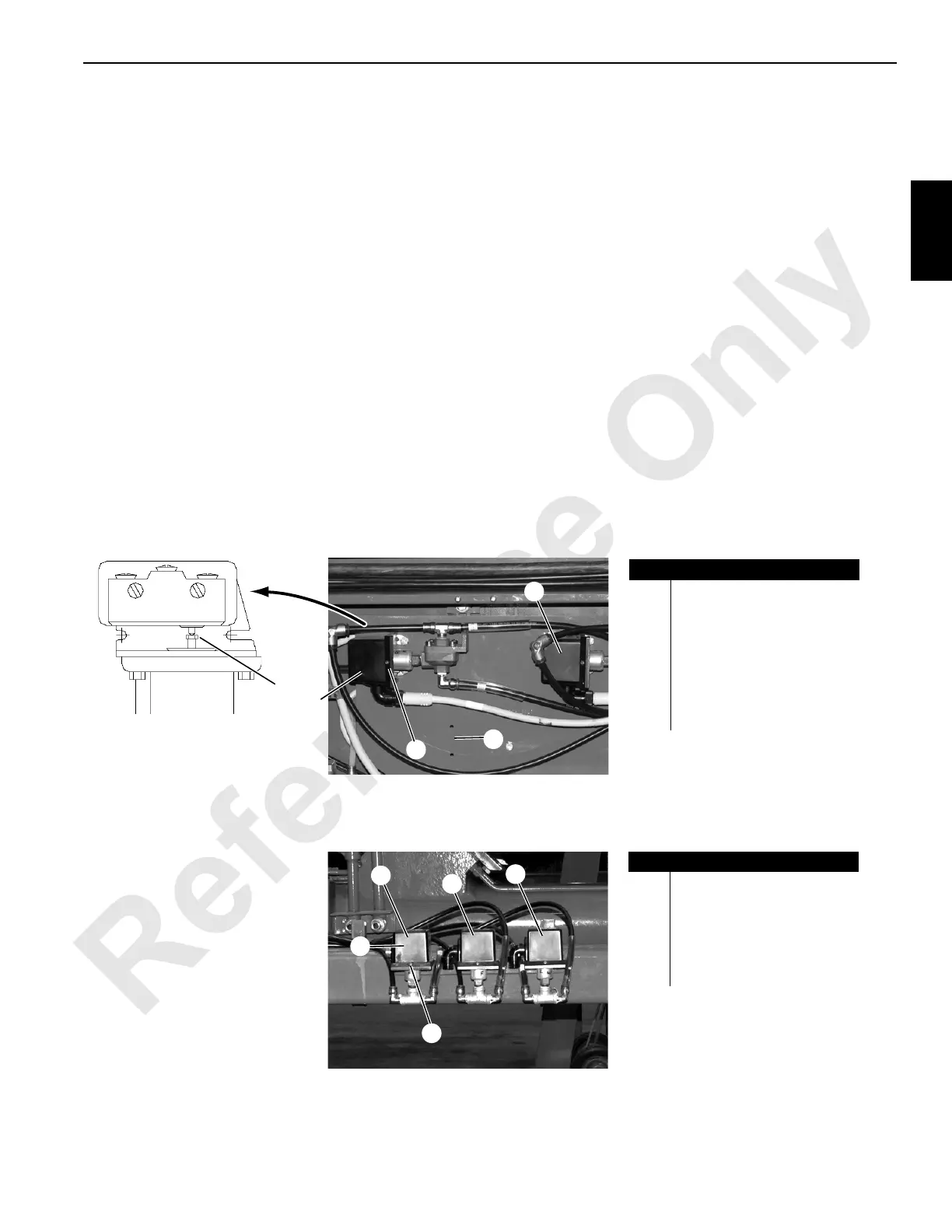

IMG_6844

Item

Description

6 Has No Function

7 Has No Function

8 Pressure Switch Cover

9 Cover Screw (typical)

10

Low System Air Pressure

Safety Switch

Left Side of Crane Under Cab

Loading...

Loading...