Manitowoc Published 11-06-15, Control # 040-13 5-9

2250 SERVICE/MAINTENANCE MANUAL HOISTS

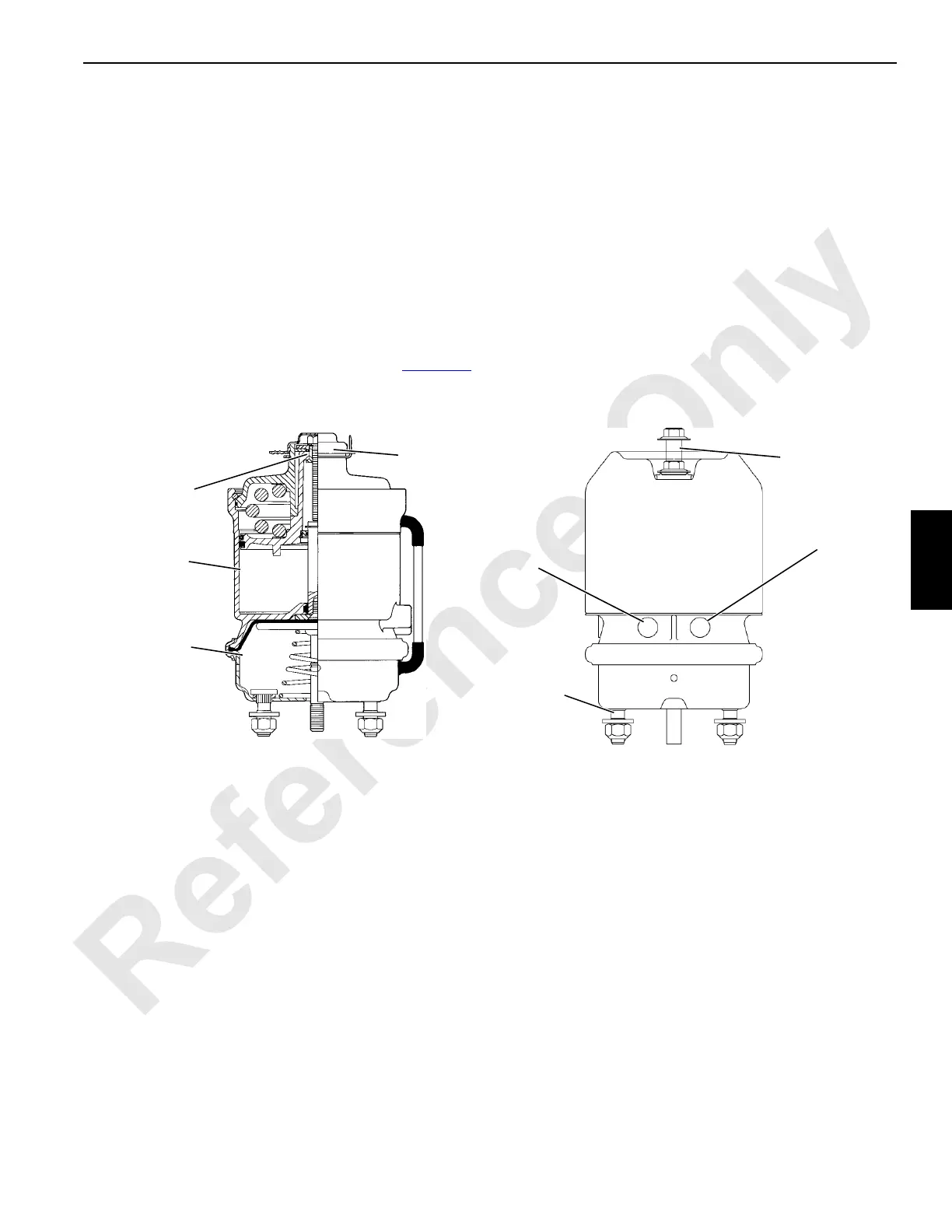

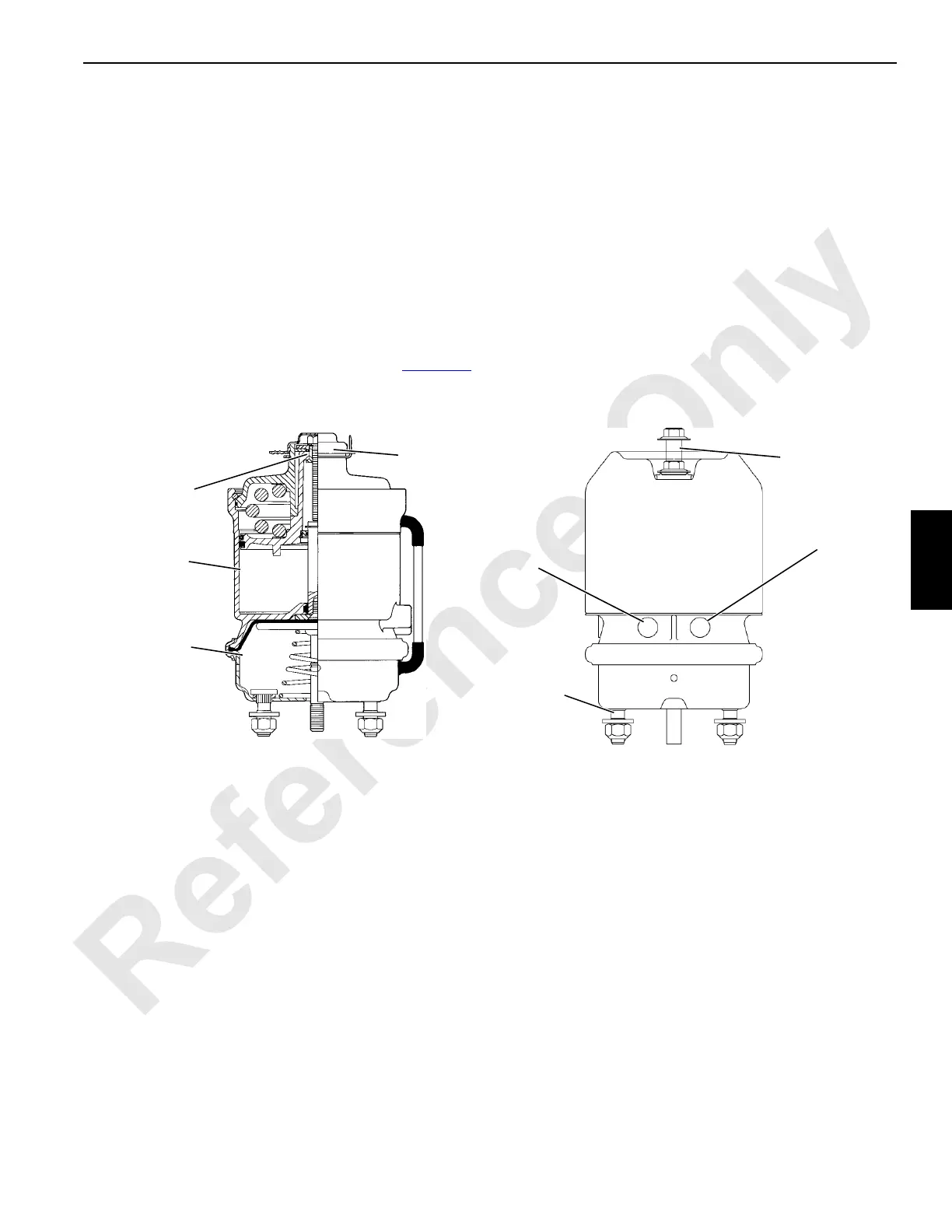

DRUM BRAKE INSPECTION AND

ADJUSTMENT

Description

Each drum brake consists of an external, contracting band-

type brake and two actuators. On single drum shafts, the

brake is mounted on the left end of the drum. On split drum

shafts, a brake is mounted on the outboard end of both

drums. Independent drum drive has two brakes, one

mounted on the left end of drum shaft and the other mounted

on the right end.

NOTE: There are two types of brake actuators used. A

past production type actuator and a current

production type actuator is shown in Figure 5-6

.

Customers ordering replacement brake actuators

will receive the current type.

Each actuator has two chambers which provide two separate

braking systems for each load drum:

• The spring chamber provides a spring-applied, air-

released parking brake. In the full power mode, the

parking brake is applied and released automatically by

the load drum control.

• Only one service chamber is used. It provides an air-

applied, spring-released working brake. Braking control

is variable, from fully applied to fully released, through

the use of a treadle valve.

The operator shall be seated and the engine must be running

to operate the drum controls and parking brakes during the

inspection, adjustment, and overhaul steps. The drums are

automatically parked and the handles are inoperable when

the operator is out of the seat or the engine is off.

FIGURE 5-6

Drum Brake Actuator Identification

(shown with working and parking brakes released)

Brake Release

Bolt (installed)

S153

Spring Chamber

(Parking Brake)

Service Chamber

(Working Brake)

Dust

Cap

Past Production

Actuator

Mounting Studs

Service Brake Port

(Working Brake)

Current Production

Actuator

192789-2

Service Brake Port

(Parking Brake)

Brake Release

(Shown Caged)

Loading...

Loading...