Manitowoc Published 11-06-15, Control # 040-13 7-17

2250 SERVICE/MAINTENANCE MANUAL POWER TRAIN

ENGINE COOLING SYSTEM FILL —

CURRENT PRODUCTION TIER 4

General

The cooling system consists of a horizontal radiator

(mounted above the engine) and a variable-speed,

hydraulically driven blower-type fan.

Cooling System Operation

Cooling system flow is illustrated in Figure 7-16.

The cooling system is of the deaeration type, which

continually removes air from the system, as follows:

• A small percentage of total coolant flow is circulated

through a vent line to the radiator.

• Since coolant circulation is very slow in the radiator, air

separates from the coolant.

• Air collects at the top of the radiator. When pressure

rises to 16 psi (1,03 bar), relief in fill cap opens to

exhaust air through overflow line.

• Deaerated coolant returns to the system through a

make-up line.

Maintenance

Daily Maintenance (Start of Each Shift)

Check coolant level when cold (see Figure 7-17):

1. Coolant should be at full level of cold gauge.

2. Fill cooling system as required with coolant. To ensure

adequate fill, do not add coolant at a rate greater than

5 gallons/minute (18.9 liters/minute).

See engine manufacturer’s manual for antifreeze and

coolant additive recommendations.

3. Look for coolant leaks while engine is running and

correct if found.

Semiannual Checks

1. Inspect fill cap and thermostat for proper operation and

replace worn parts:

- Fill cap relieves at 16 psi (1,03 bar)

- Thermostat closes at 180°F (82°C) and opens fully

at 202°F (94°C)

2. Inspect water pump belts for wear and proper

adjustment (see engine manufacturer’s manual).

3. Inspect cooling system hoses for deterioration and other

defects. Replace as necessary.

4. Tighten hose clamps.

5. Clean all dirt and other debris from outside of radiator.

6. Check that overflow line on tank is open.

Draining Radiator

Drain radiator system, as follows:

1. Stop engine.

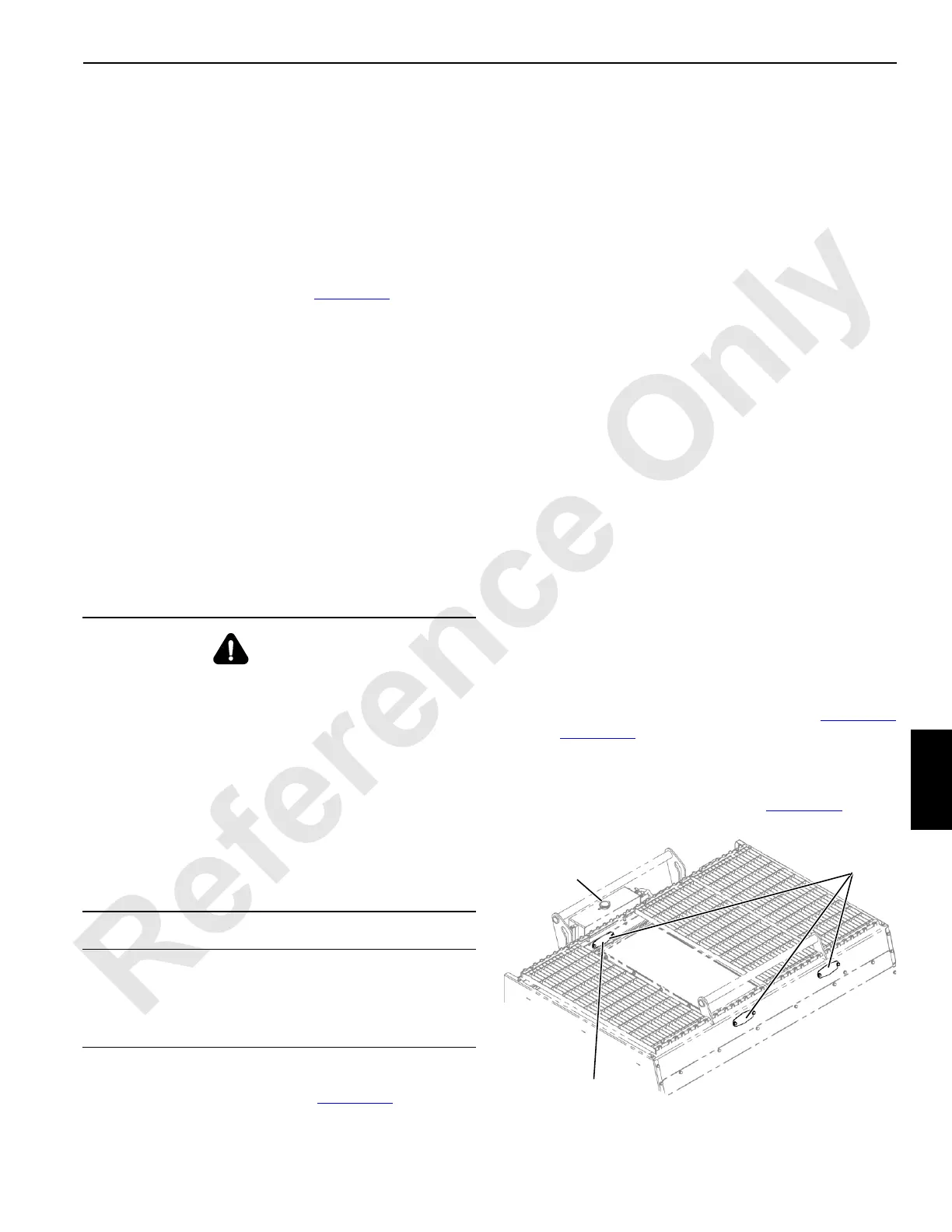

2. Remove covers over three bleed valves — two at front

end of radiator and one at back end (see Figure 7-20

and Figure 7-21).

3. Open three petcock bleed valves located at both ends of

radiator under access covers.

4. Remove radiator surge tank fill cap (Figure 7-17

).

WARNING

Burn Hazard!

Avoid personal injury from heated coolant spray or steam

— do not remove radiator cap from hot engine. Stop

engine and wait until coolant temperature is below 120°F

(50°C). Then:

• Place a protective covering over fill cap.

• Slowly turn fill cap counterclockwise until it stops at

safety detent.

• Wait until pressure (indicated by hissing sound) is

completely relieved.

• Depress fill cap and turn counterclockwise to remove.

CAUTION

Overheating Hazard!

Avoid engine damage from overheating — do not allow

coolant level to go below low level on gauge.

FIGURE 7-20

Front of Radiator

Access

Cover

Bleed Valve

(3 places under covers)

Radiator Surge

Tank Fill cap

Loading...

Loading...