Manitowoc Published 11-06-15, Control # 040-13 1-33

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

EPIC

®

Programmable Controller (PC)

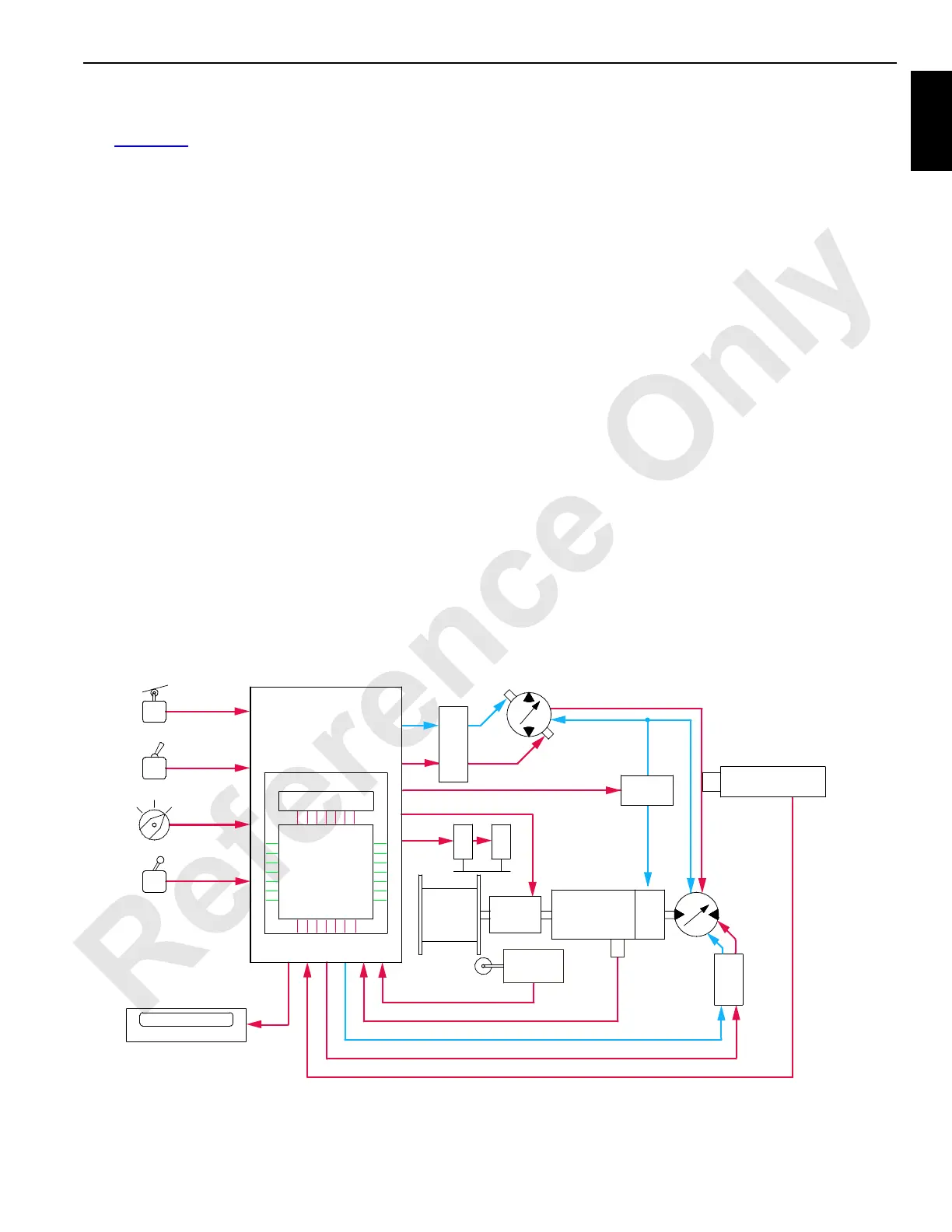

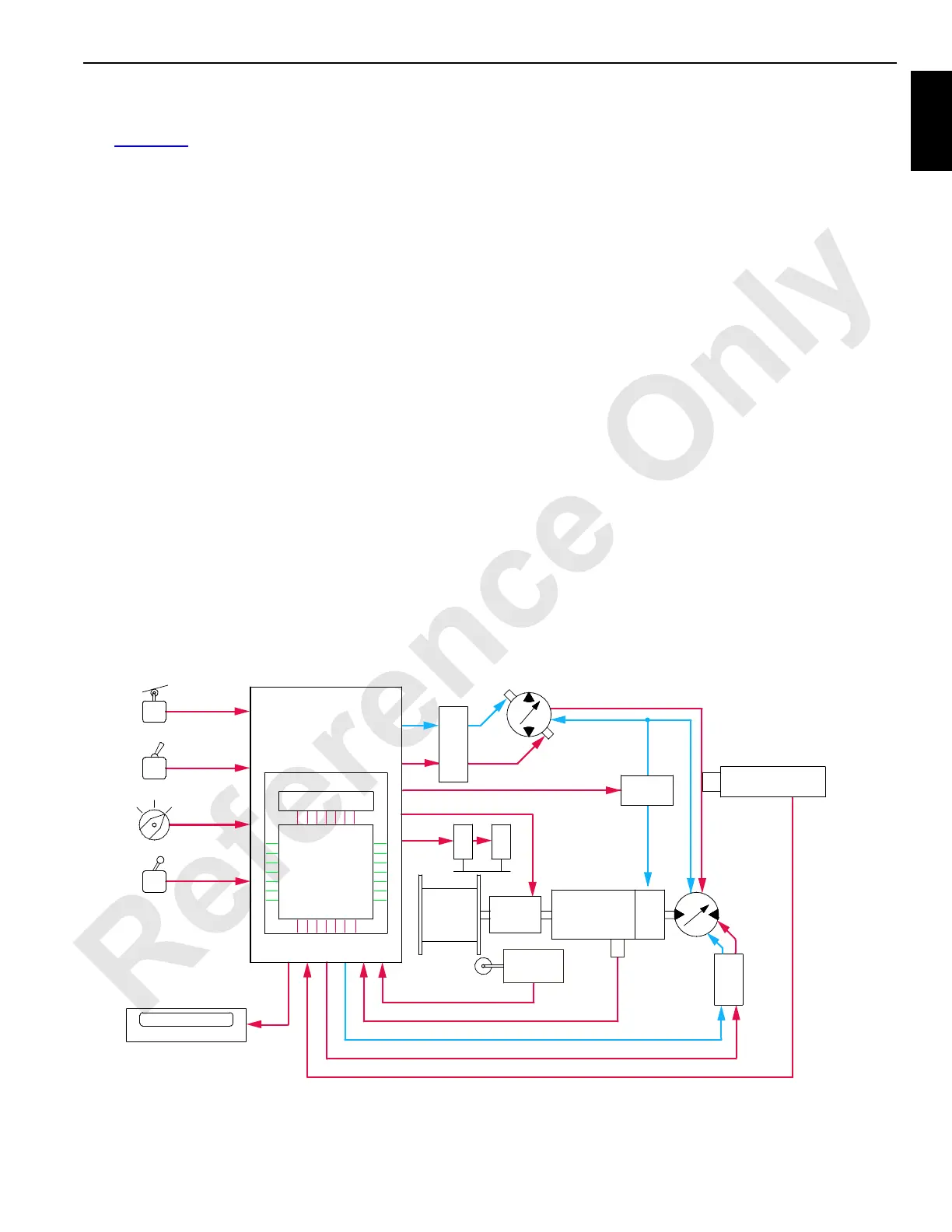

See Figure 1-16 for the following procedure.

The Model 2250 crane’s boom, load lines, swing, crawler

tracks, and accessory components are controlled

electronically with the EPIC (Electrical Processed

Independent Control) system. This simplifies the crane's

electrical control system by avoiding mechanical control

switches and relays. Standard or custom programming

allows the PC (Programmable Controller) to automatically

adjust each operational mode's acceleration rate and speed,

apply brakes, and engage clutches.

The PC receives and sends both analog and digital input/

output voltages. Analog input/output voltages are either AC

or DC variable voltages or currents that are in a pulse train.

Digital input/output voltages are 12 volt nominal voltages that

are either 0 = off or 1 = on.

The PC uses the binary system. The binary system is based

on binary multiples of two and only recognizes 0 = off or 1 =

on. Basic counts of this system are exponents of the number

two. These exponents are formed in words, called bytes, of

eight numbers each. The eight numbers are 1, 2, 4, 8, 16, 32,

64, and 128 for an 8-bit controller or a combination of up to

255 bytes. These bytes represent electrical inputs/outputs to

the controller.

The controller processes the information by comparing it to

programming requirement and data information. The PC

then provides appropriate output commands to crane control

devices. See Crane Diagnostics topic in Section 10 of this

manual.

Digital Display

Digital display screen on front console shows operating

conditions, operating limits, and system faults monitored by

the PC. Access information by scrolling to the desired

display screen with scroll switch. System messages are

shown in Tables in Digital Display Readings in Section 3 of

the Operator Manual.

Rated Capacity Indicator/Limiter (RCL)

The RCL system has its own PC (Programmable Controller)

and is part of the EPIC system. Load charts are specific for

each crane model. For complete information see separate

Rated Capacity Indicator/Limiter Operation manual.

Crane Modes

• Standard mode is for all normal load-handling

operations.

• In Setup mode, the program allows limited operation, but

boom-up limit is bypassed.

• In Luffing Jib mode, the program allows standard mode

load handling operations plus luffing jib operation.

• In Tandem Drum mode, the program allows operation of

both load drums on a split drum shaft, or both front and

rear load drums are operated at the same time in full

power operation with a single control handle.

RF-08

COMMAND VOLTAGES IN

MONITORING

VOLTAGES OUT

BRAKES

DIGITAL DISPLAY

VOLTAGES

TO

COUNTS

TO

VOLTAGES

MEMORY

PROCESSING

PROGRAMMABLE

CONTROLLER - PC

SENSOR VOLTAGES IN

MOTOR SPEED SENSOR (IF CLUTCH EQUIPPED)

PRESSURE

SENDERS

OPERATIONAL VOLTAGES OUT

PUMPS

EDC

BRAKE

VALVE

DRUM

SPEED

SENDERS

MOTORS

CLUTCH

IF

EQUIPPED

DRUMS

SELECTORS

CONTROL

HANDLES

SWITCHES

LIMIT

SWITCHES

GEAR

REDUCER

PCP

B

R

A

K

E

FIGURE 1-16

Loading...

Loading...