HOISTS 2250 SERVICE/MAINTENANCE MANUAL

5-24

Published 11-06-15, Control # 040-13

SLACK LINE SENSOR ADJUSTMENT

General

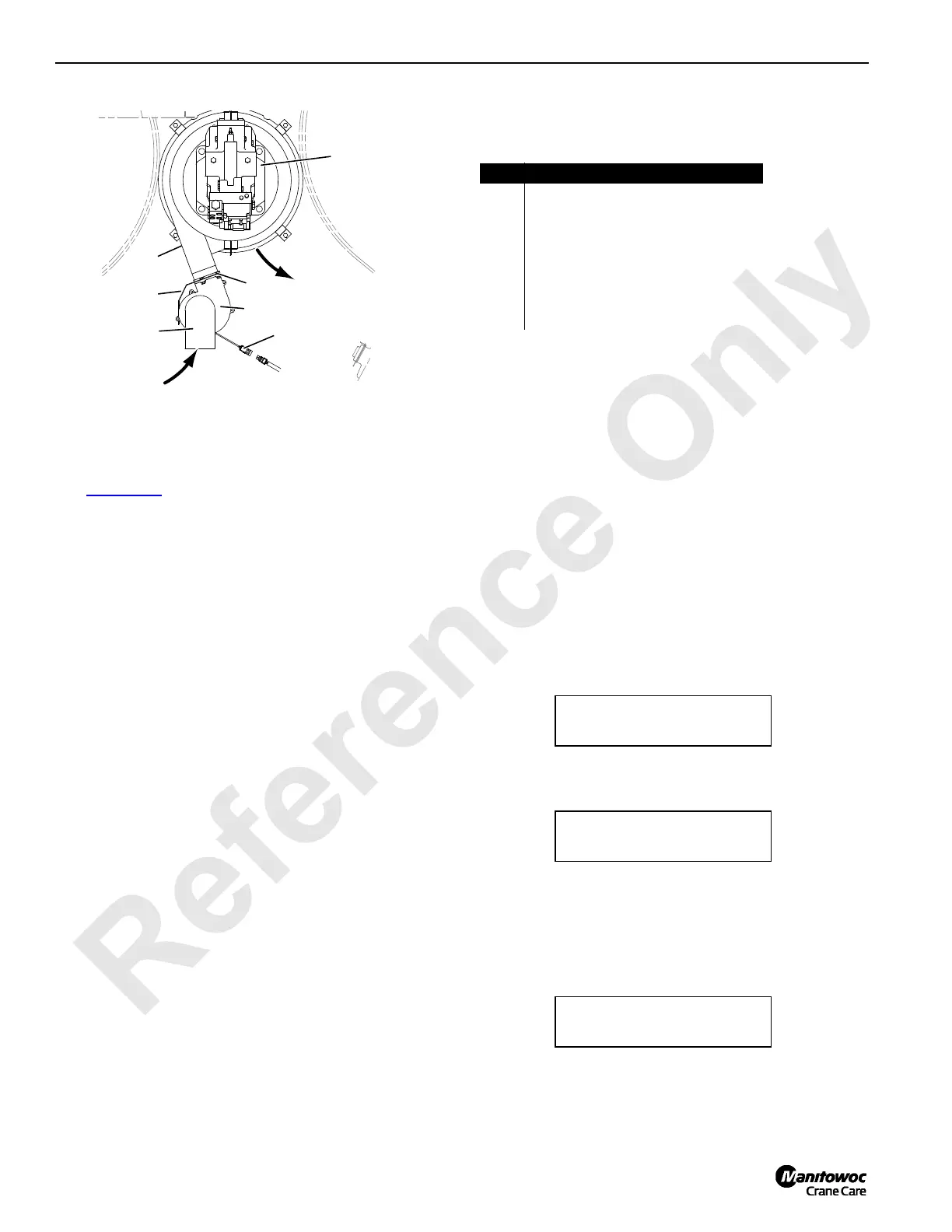

See Figure 5-20 for the following procedure.

A laser light sensor mounted on the boom butt wire rope

guide detects a slack load line condition at either front or rear

drum. The RCL detects a slack line condition at boom angles

of 70 degrees and above, if a line pull of one half the

calibrated weight ball is reached. In either case the operator

is alerted as follows:

• Operating limit alert comes on (yellow light and buzzer in

operator’s cab)

• SLACK LINE INDICATOR message appears on display

screen

• Drum inoperable in down direction

To correct a slack line condition, haul-in load line on affected

load drum. The operating limit alert goes off.

At least weekly, check the slack line sensor for correct

operation and clean the optical lens of the transmitter and

receiver. Operating limit alert could be accidentally

activated if either lens is dirty.

Light Sensor Adjustment

Lower the boom onto blocking at horizontal to service the

slack line sensor. The transmitter mounted at the sensor

junction box is fixed. Make all adjustments at the receiver.

1. Stop crane engine and place run/stop switch in RUN

position.

2. Check that transmitter is emitting a light beam.

3. Loosen bracket screws at receiver.

4. Position receiver in line with transmitter light beam by

moving brackets in slots.

NOTE: The yellow LED on the receiver turns on when the

light beam is received by the transmitter.

5. Tighten bracket screws when light beam is correct.

6. If above procedure does not correct the problem,

calibrate the slack line indicator.

Slack Line Indicator Calibration

To calibrate slack line indicator, lower all load blocks/weight

balls to the ground. Leave a little slack line at the first fall.

1. Scroll through diagnostics to slack line calibration

screen.

2. Confirm slack line screen to begin calibration process.

3. The screen will ask what load sheave you are using, 1

through 4.

4. To change an answer, use the select switch.

5. To verify an answer is correct, press confirm switch and

move on to next sheave.

6. After all four sheaves have been verified YES or NO, the

controller starts to calibrate load cells.

After screen counts to 100%, calibration is complete.

A

Item Description

1 Electric Plug

2Blower

3 Bolts with Nut and Lock Washer (4)

4 Guard

5 Inlet Elbow

6 Shroud

7 Drum Motor

Air

Exhaust

Air Inlet

FIGURE 5-19

1

2

3

4

5

6

7

SLACK LINE INDICATOR

CONFIRM TO BEGIN

SLACK LINE INDICATOR

SHEAVE 1 IN USE? YES

SLACK LINE INDICATOR

0% COMPLETE

Loading...

Loading...