HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-38

Published 11-06-15, Control # 040-13

SOLENOID VALVE MAINTENANCE

Operation

Normally Closed

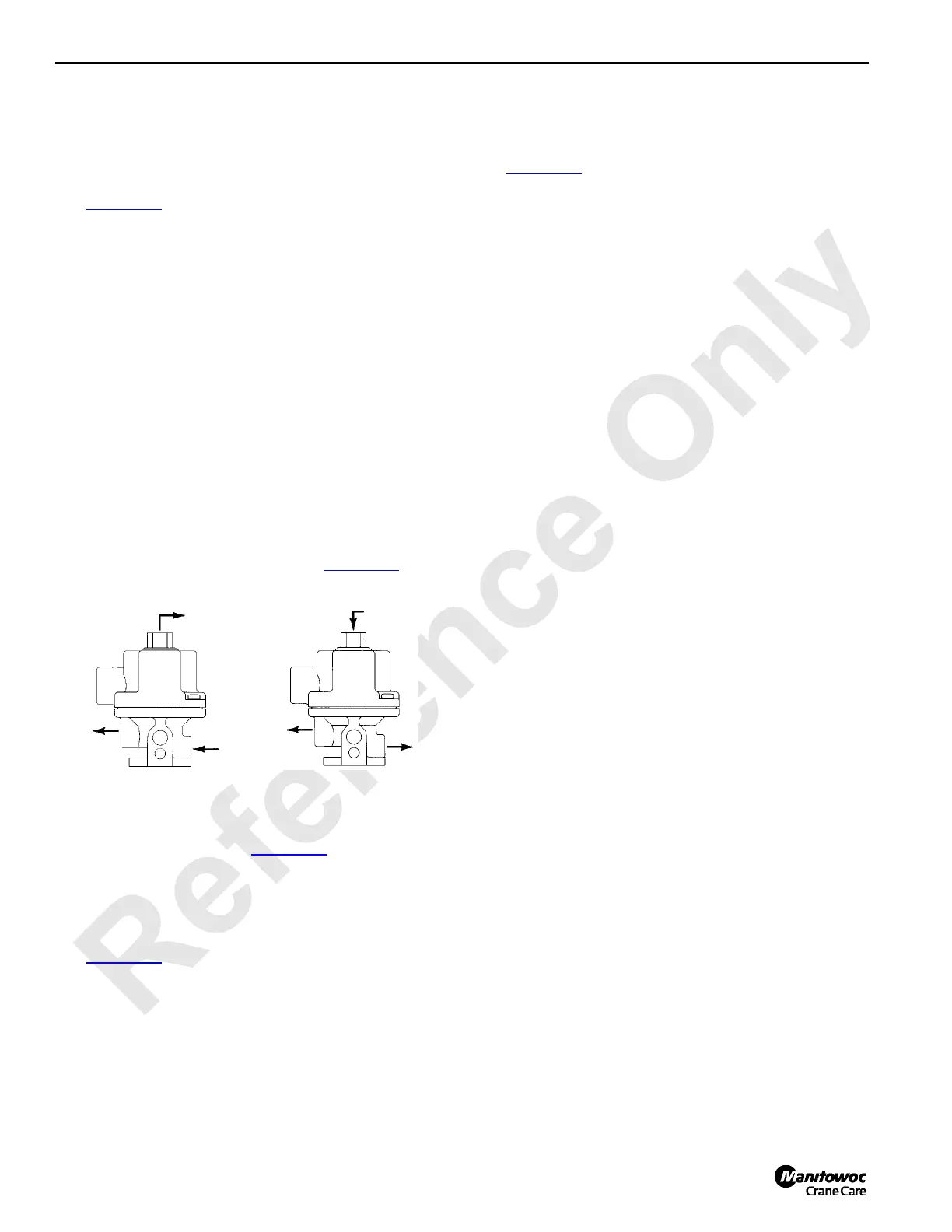

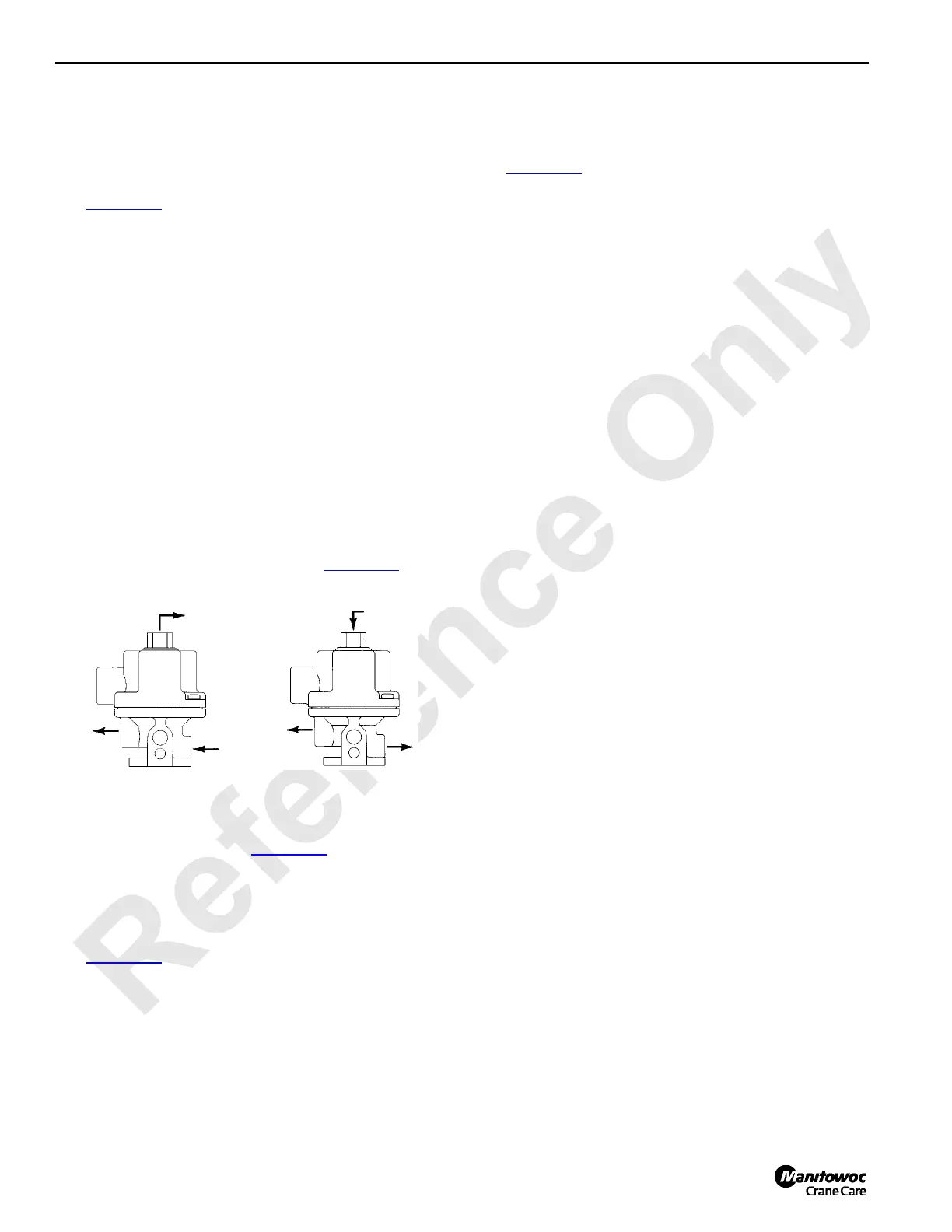

See Figure 2-39 for the following procedure.

Pressure is applied to inlet port P. With the valve

deenergized, air at port P is sealed off by the force of the

plunger return spring and the seal in the plunger assembly.

Cylinder port A is open to exhaust port E.

When current is applied to the coil, the plunger assembly

moves to open inlet port P to cylinder port A. Exhaust port E

is sealed off by the plunger assembly.

Normally open operation is just the opposite.

Air Line Connection

The solenoid valve has three ports identified as follows:

P = Inlet from control valve

A = Outlet to cylinder

E = Exhaust

For normally-closed operation the air lines must be

connected to the valve ports as shown in Figure 2-39

.

For normally-open operation the air lines must be connected

to the valve ports as shown in Figure 2-39

.

NOTE: Improper connection of air lines will cause

improper system operation.

Electrical Connection

See Figure 2-40 for the following procedure.

If the coil housing is located in an inconvenient position, it

may be oriented in 90 degree steps. For 90 degrees, two

housing screws must be removed and two housing plate

screws must be relocated. For 180 degrees, only the two

housing screws have to be removed. The screws must be

reinstalled after orientation.

Maintenance

Troubleshooting

See Figure 2-40 for the following procedure.

If the valve fails to operate at all, check the coil for shorted or

open turns. Also check supply current. See below if coil is not

damaged.

External Leakage

If leakage occurs around the sleeve assembly, the metering

pins, or the manual override stem, the o-rings should be

removed and inspected for imperfections.

Sticking Or Internal Leakage

If the valve leaks internally or the plunger sticks in the

energized position, examine the soft inserts in the plunger

ends or inside the sleeve assembly for excessive dirt or

wear. If the inserts show considerable wear, the plunger

should be replaced.

Noise

If the valve develops a loud buzzing noise, first check voltage

and pressure to determine if they correspond to the

nameplate rating. Examine the inside of the sleeve assembly

and the upper portion of the plunger and remove all foreign

matter imbedded in these parts. Be careful not to damage

the sleeve seat.

NOTE: Do not expose plunger assembly or o-rings to any

type of commercial cleaning fluid. Plunger

assembly and o-rings may be cleaned with a mild

soap and water solution.

Disassembly

Shut off pressure and electricity to the valve. The valve does

not have to be removed from the line.

Remove the screws from the housing. Remove the housing

from the valve assembly. After removing the housing, the

yoke and coil can be removed with an upward twisting

motion.

Remove the screws holding the housing plate to the body

(these screws are shorter than the housing screens). The

housing plate can be removed. The sleeve assembly and

plunger can then be removed.

Reassembly

Place the housing plate over the sleeve assembly. Use a

light oil on the o-ring flange seal. Always assemble the o-ring

to the sleeve assembly before inserting in valve bodies.

Make sure the plunger and the return spring are in place and

then push the sleeve assembly, along with the housing plate,

down in place on the body with a slight twisting motion. Hold

the housing plate down and replace the two screws (these

are the shorter ones). Tighten the screws to 18 ± 3 in-lb. (2 ±

FIGURE 2-39

“P”

“A”

“E”

Normally Closed

S126 “P”

“A”

S125

Normally Open

“E”

Loading...

Loading...