INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-72

Published 11-06-15, Control # 040-13

Hydraulic Quick Disconnect

General

A self contained hydraulic system makes the mechanical

connections between the adapter frame and rotating bed

hydraulic lines during assembly/disassembly.

When cab power switch is on and engine fluid pressure

switch is closed (engine not running), power is available to

hydraulic quick disconnect switch at remote start junction

box on right side of rotating bed. Hydraulic quick disconnect

is operational after the following connections are made:

1. Connect boom stop electrical cable from rotating bed to

junction box plug and couplers on right side of adapter

frame.

2. Connect swing lock air lines from rotating bed to junction

box plug and couplers on right side of adapter frame.

3. Connect luffing jib pawl air lines from rotating bed to

junction box plug and couplers on right side of adapter

frame.

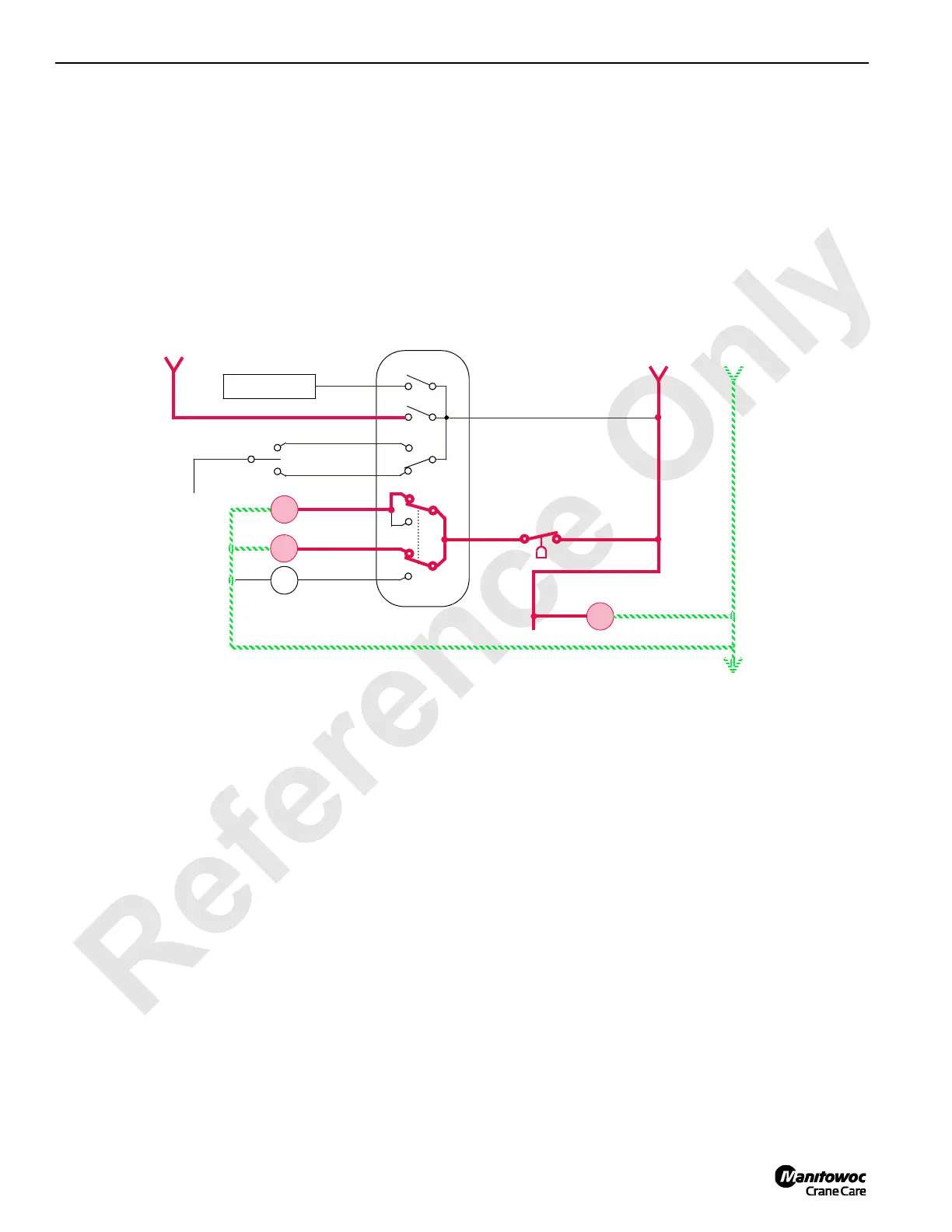

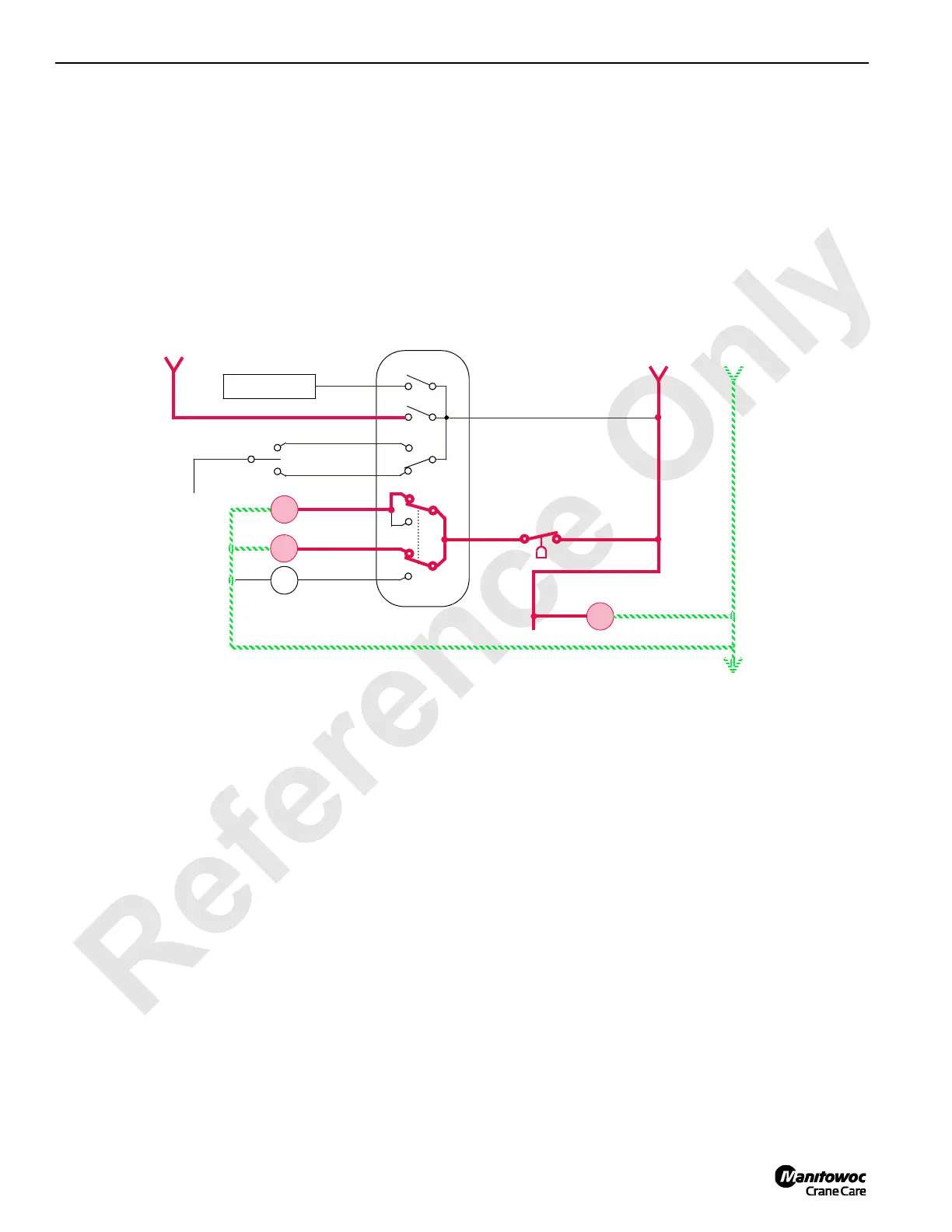

Hydraulic Quick Disconnect Engage

When hydraulic quick disconnect switch is moved to engage

position, an output signal is sent to engage hydraulic

solenoid HS-33 and hydraulic disconnect relay (HDR). The

relay sends an output signal to enable hydraulic quick

disconnect motor in the engage direction.

When hydraulic solenoid HS-33 is enabled the fluid from the

motor flows past relief valve that limits system pressure to

300 psi (21 bar), through the solenoid valve to piston end of

frame cylinder.

Frame cylinder extends rotating bed coupling plate and

sleeve plates together toward the adapter frame coupling

plate. Hydraulic quick disconnect closes as the fluid from rod

end returns to tank through sequence valve and then

solenoid HS-33.

Fluid also flows to the piston end of each coupling cylinder.

Fluid from each coupling cylinder rod end flows back to tank

through solenoid HS-33. Coupling cylinders extend to close

quick disconnect, completing hydraulic line coupling

between rotating bed and adapter frame.

Hydraulic Quick Disconnect Disengage

When hydraulic quick disconnect switch is moved to,

disengage position, an output signal is sent to disengage

hydraulic solenoid HS-34 and hydraulic disconnect relay

(HDR). The relay sends an output signal to enable hydraulic

quick disconnect motor in the disengage direction.

When hydraulic solenoid HS-34 is enabled the fluid from the

motor flows past relief valve that limits system pressure to

300 psi (21 bar).

Fluid from solenoid valve flows to rod end of side of each

coupling cylinder and through sequence valve to rod end of

main cylinder. A check valve blocks flow to main cylinder.

Then the coupling cylinders retract sleeve plate first to

unlock the couplings. Then at 200 psi (14 bar), sequence

valve opens to allow flow to frame cylinder. Frame cylinder

retracts, separating rotating bed coupling plate from adapter

frame coupling plate.

Hydraulic quick disconnect opens, separating the coupling of

hydraulic lines between rotating bed and adapter frame as

the fluid from piston end of the cylinders returns to tank

through solenoid HS-34.

7

ENGAGE

GND

PROGRAMMABLE

CONTROLLER

68R

7

3

START

RUN/STOP

CAB

POWER

REMOTE START

JUNCTION BOX

RF-43

RUN/STOP

1500 RPM

5DA

3

OIL PRESSURE

HYDRAULIC

DISCONNECT

DISABLE

0

HS

34

HDR

HS

33

DISENGAGE

HYDRAULIC

MOTOR

K1

FIGURE 1-43

Loading...

Loading...