Manitowoc Published 11-06-15, Control # 040-13 1-37

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

When a control handle is moved from off, an input voltage in

the handle command direction is sent to the PC. The PC

does not release selected brake until pressure memory

holding pressure is reached to hold the load, as determined

by the system pressure sender.

When hydraulic brake solenoid is enabled, selected brake

valve shifts to block tank port and to supply pilot pressure

from boom/luffing jib charge pump to release selected brake.

When a brake solenoid is disabled, the solenoid valve closes

to block charge pump port and to vent brake pressure to

tank. The spring brake applies. If brake pressure or electrical

power is lost when operating, brakes apply.

Load Drum Air Brakes

See Figure 1-20 for the following procedure.

Each load drum brake has two air cylinders, and each

cylinder has two chambers. The first brake cylinder chamber

is a spring-applied/air-released brake controlled by the PC.

The other part of the first cylinder chamber is a working brake

for free fall that is air-applied/spring-released. The second

brake cylinder chamber is a spring-applied/air-released

brake controlled by the PC and the other brake cylinder

chamber is not used.

Release the load drum brakes by placing selected load drum

brake switch in off position. The PC enables the brake

solenoid when load pressure memory is reached.

When the PC enables Drum 1, 2 or 3 load drum brake

solenoid (AS-7, AS-9, or AS-11), regulated air shifts brake

relay. This allows manifold air to close quick release valves.

Air flows to brake cylinder chambers, compressing the

springs to release brake. With selected load drum brake

released, load drum motor can hold the load when operating

in full-power operation.

In Standard mode when the selected load drum control

handle is in off position or selected load drum brake switch is

in off position, brakes are spring-applied. Air in brake

cylinders is exhausted to ensure that load drum brake spring

applies. Exhausted air from brake cylinders goes through

quick release valves when sealing pressure is exhausted off

the valve diaphragms, opening exhaust ports. This occurs

when pilot pressure is removed from brake relay valve.

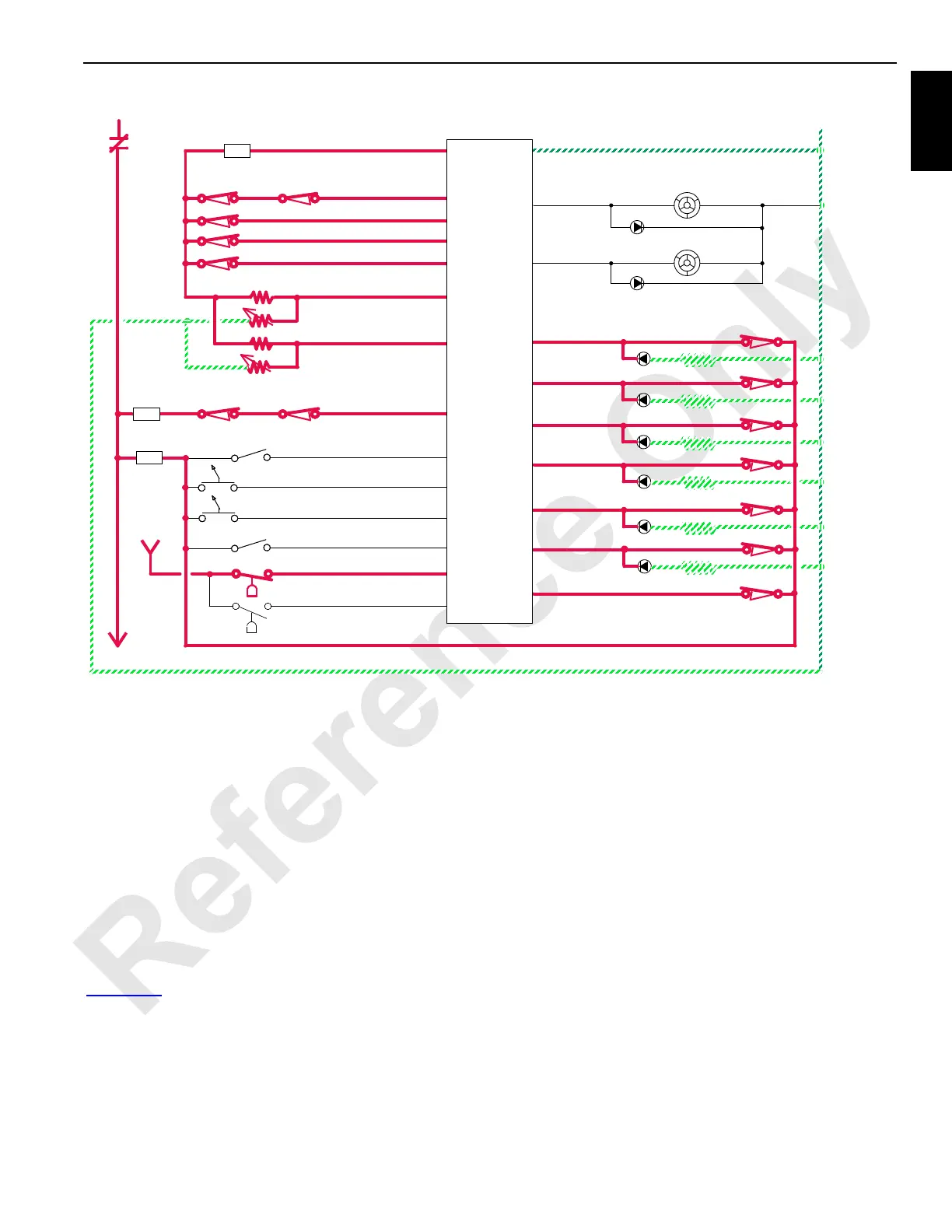

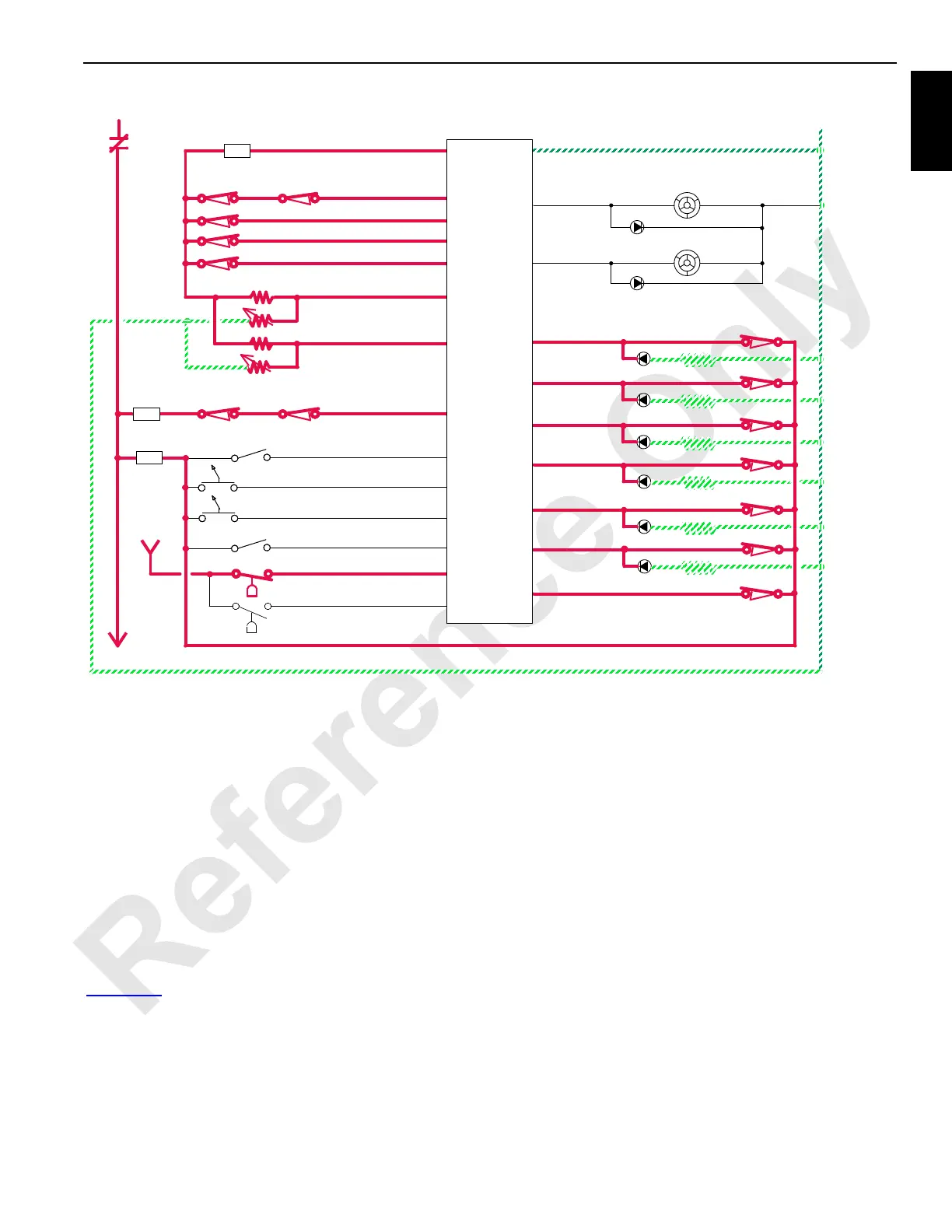

0

0

K1

F10

8

8D

LIMIT BYPASS

WB-25

87FA 87F

MAXIMUM ANGLE LIMIT

MAX. WORKING ANGLE LIMIT

BLOCK UP LIMIT WB-06

WB-17

WA-35

LIMIT SWITCH

EQUALIZER

LIMIT SWITCH

BOOM STOP

8M

WD-13

UPPER

MAIN

LOWER

MAIN

REGULATED 10V DC OUT

RF-11

5A

SYSTEM FAULT ALARM

WC-34

WC-35

OPERATING LIMIT ALARM

LIGHT

5A

WB-10

SEAT SWITCH

WB-22

LEFT REAR DRUM

MINIMUM BAIL LIMIT DRUM 1

WB-03

WB-14

BOOM UP LIMIT

MAXIMUM BAIL LIMIT DRUM 1

WB-02

MINIMUM BAIL LIMIT DRUM 2

WB-08

MAXIMUM BAIL LIMIT DRUM 2

WB-07

LIGHT

LUFFING JIB LIMIT BYPASS

WE-14

ENGINE OIL PRESSURE

WD-08

ENGINE COOLANT TEMP.

WD-09

3

8D

MINIMUM BAIL LIMIT DRUM 3

WB-04

MAXIMUM BAIL LIMIT DRUM 3

WB-05

F7

WA-17

WA-18

HYDRAULIC FLUID TEMP.

HYDRAULIC FLUID LEVEL

MINIMUM ANGLE LIMIT

WB-16

3A

10A

CONTROLLER

PROGRAMMABLE

FIGURE 1-19

Loading...

Loading...