Manitowoc Published 11-06-15, Control # 040-13 5-13

2250 SERVICE/MAINTENANCE MANUAL HOISTS

b. Connect a 0 to 150 psi (0 to 10,3 bar) air pressure

gauge to out port between valve and actuator.

c. Depress pedal so it is approximately 1/32 in (0,8

mm) from touching bumper. Gauge should read 115

to 125 psi (7,9 to 8,6 bar).

Do not set pressure higher than 125 psi (8,6 bar).

d. If required, loosen jam nut (7) and tighten set screw

(8) to increase pressure. Loosen set screw to

decrease pressure. Securely tighten jam nut to lock

adjustment.

e. Release brake pedal to fully raised position; gauge

should read 0 psi (0 bar). If required, loosen jam nut

(9) and turn screw (10) in until pressure is 0 psi (0

bar). Securely tighten jam nut to lock adjustment.

f. Remove gauge.

g. Repair or replace valve if correct pressures cannot

be obtained.

Brake Actuator Overhaul

Removal

See Figure 5-7 for the following procedure.

1. Read precautionary steps given after heading.

2. Lower load block, weight ball, or bucket to ground from

drum being serviced so wire rope is slack.

3. If equipped with three drums, use drum selector to select

desired rear drum, right or left.

4. Fully release drum working brake (brake pedal up fully).

5. Turn on free-fall and turn off drum park for drum being

serviced. Drum parking brake will release.

6. Cage power spring in actuator, as follows:

Current Production:

a. Using a 3/4 in (19 mm) deep-socket wrench, turn

release bolt counter-clockwise 22 to 23 turns.

Past Production:

a. Unsnap dust cap from top of actuator.

Using a 3/4 in (19 mm) deep-socket wrench, turn

release bolt counter-clockwise until bolt and washer are

completely removed.

7. Stand clear of actuator. Turn on drum park for drum

being serviced. Parking brake will spring apply. Piston

rod may extend slightly when this step is performed.

8. Tag air lines for proper identification when reinstalling

actuator; then disconnect air lines from actuator.

9. Remove rod end pin to disconnect rod end from brake

lever.

10. Remove mounting nuts and remove actuator from

support. Actuator weighs approximately 30 lb (14 kg).

Repair

Follow instructions in manufacturer’s service manual to

properly repair actuator.

Rework – Current Production Actuators

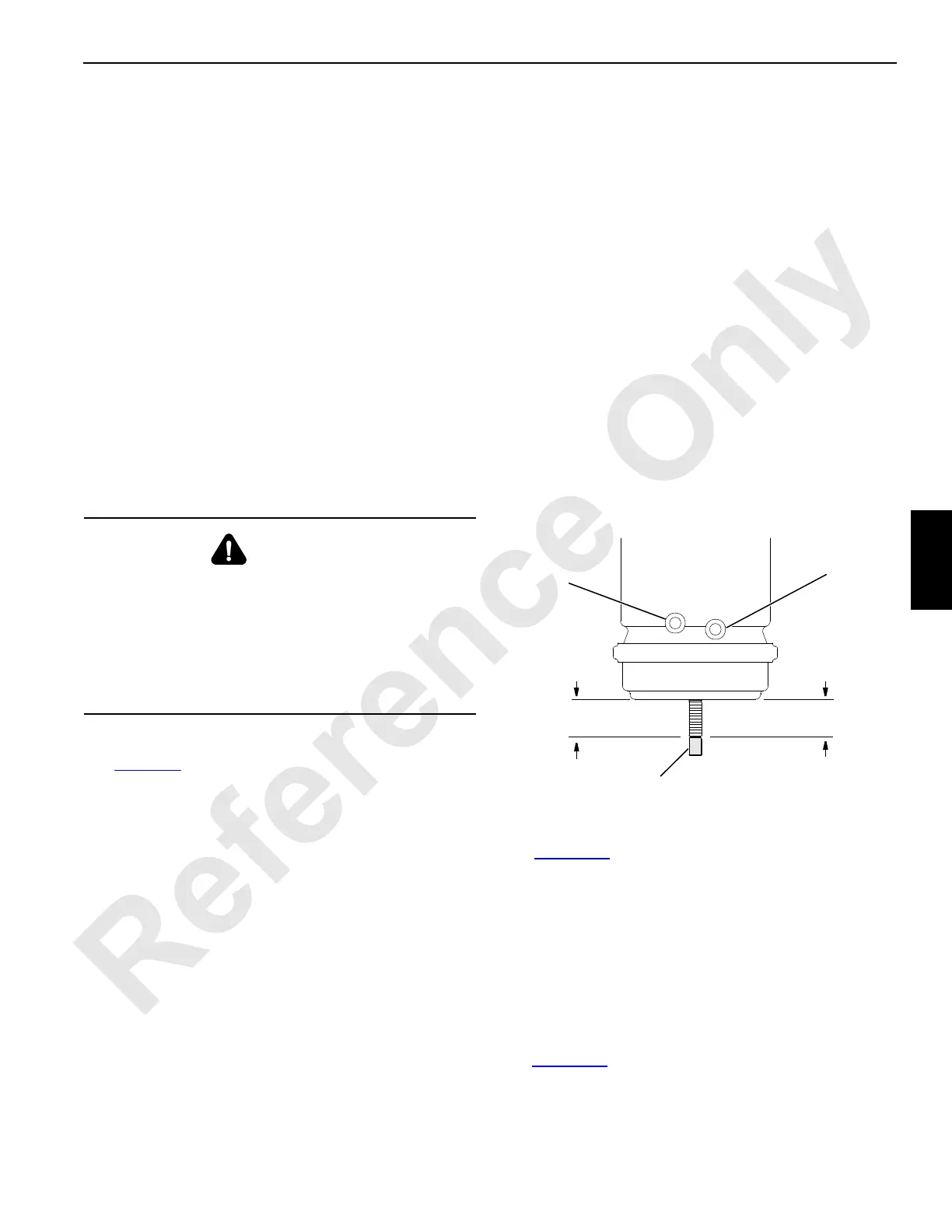

See Figure 5-10 for the following procedure.

Before installing a new or rebuilt actuator, rework it according

to the following steps:

1. Remove jam nut from piston rod end.

2. Turn spring brake release bolt clockwise until tight and

torque to 74 ft-lb (100 N•m).

3. Apply at least 90 psi (6,2 bar) air pressure to spring

brake port of actuator.

4. Cut off piston rod at 1-7/8 in (48 mm) as shown in

Figure 5-10

for standard actuators and 1-1/2 in (38 mm)

for clamshell drum actuators.

WARNING

Personnel Injury Hazard!

Actuator is spring loaded; do not attempt to disassemble

actuator while it is on crane. Remove actuator according

to the following instructions.

See instructions in manufacturer’s service manual for

proper disassembly of actuator. Otherwise, actuator will

fly apart with dangerous force.

FIGURE 5-10

1-7/8 in (48 mm)

(Split Rear)

A467

Cut Off Excess

Piston Rod

Spring Brake Port

(Parking Brake)

Service Brake Port

(Working Brake)

1- 1/2 in (38 mm)

(Full Front/Rear)

NOTE: Mounting studs

removed for clarity.

Loading...

Loading...