INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-24

Published 11-06-15, Control # 040-13

CRANE DESCRIPTION OF OPERATION

General Operation

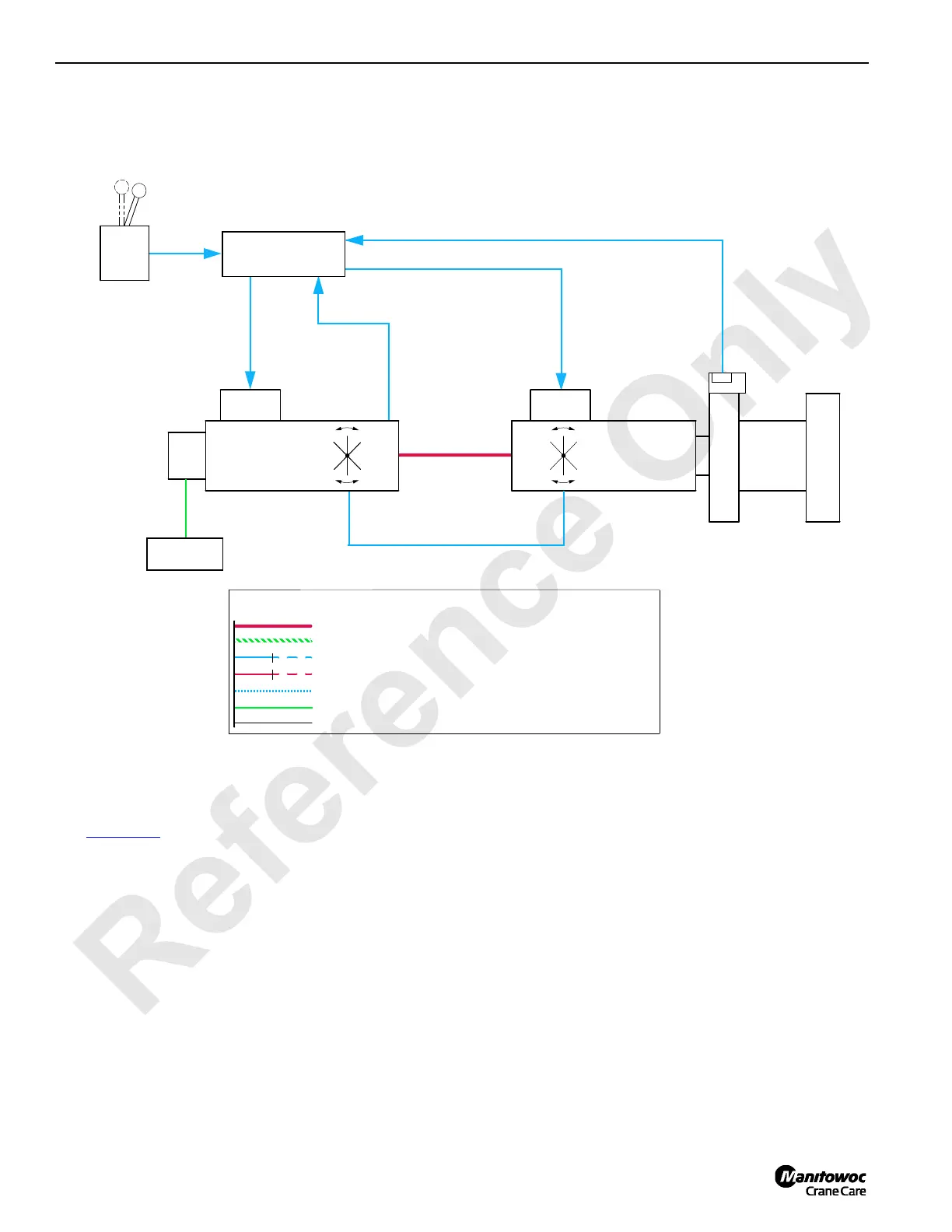

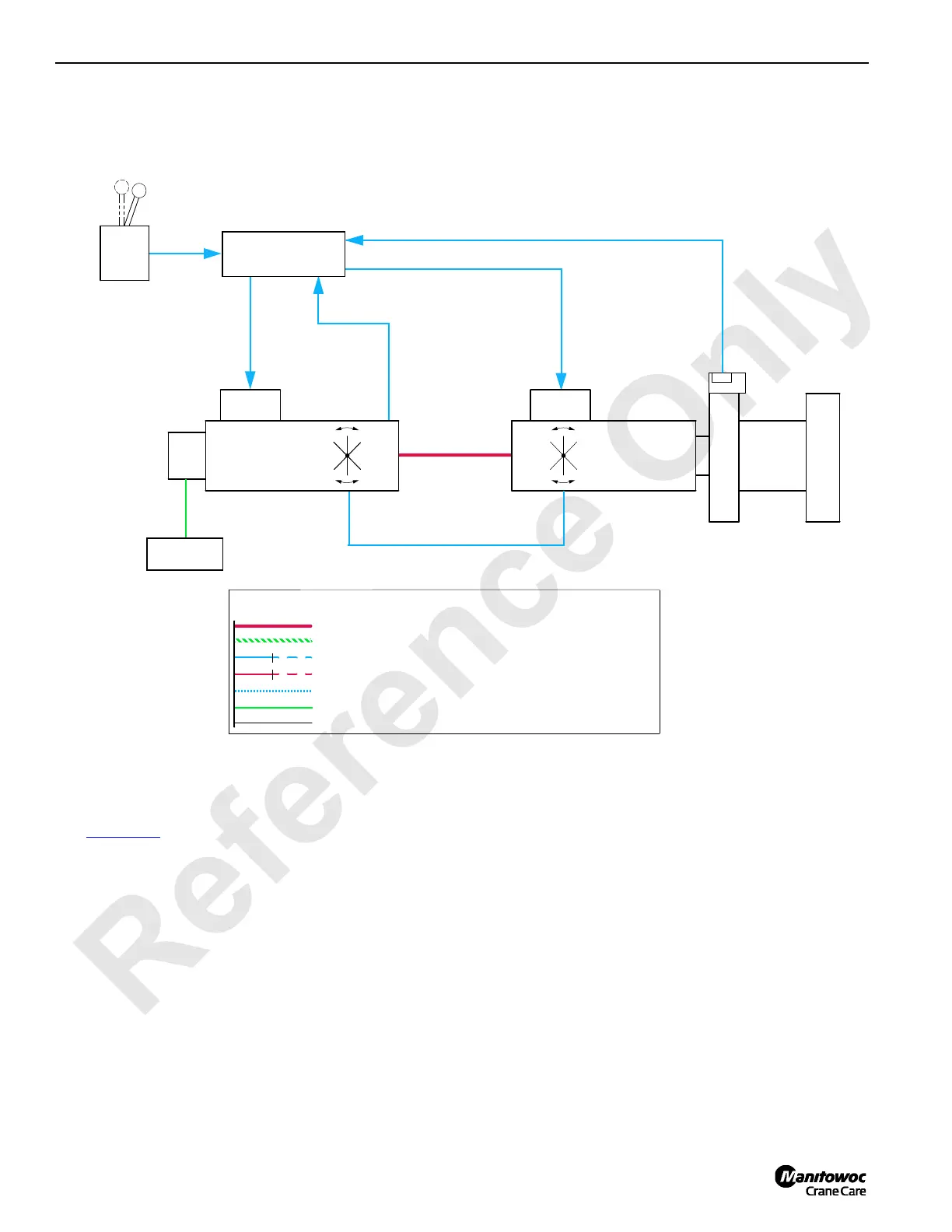

See Figure 1-10 for the following procedure.

This section describes the model 2250 powered with the

Cummins QSX15 or the Caterpillar 3406C engine. Standard

and optional equipment available for the crane is included.

Disregard any equipment your crane does not have. See the

MAX-ER™ 2000 Operator Manual for information on the

MAX-ER 2000. See MAX-ER 2000 Description of Operation

topic in this section.

The Model 2250 operating system is an EPIC

(Electrical

Processed Independent Control). Through the PC

(Programmable Controller) the independently powered

pumps, motors, and cylinders provide controller driven

control logic, pump control, motor control, on-board

diagnostics, and service information. Crane information is

displayed on digital display screen in operator’s cab.

A single diesel engine provides power to operate system

pumps through a pump drive transmission. In a closed-loop

hydraulic system, high-pressure hydraulic fluid from the

system pump drives a hydraulic motor. Pressure develops

within the closed-loop system while resistance to movement

of the load on motor is overcome. When movement begins,

pump volume displacement maintains motor speed. The

spent hydraulic fluid from motor outlet returns directly to

pump input. The crane closed loop systems are swing, right

travel, left travel, boom hoist, load drums, and luffing jib hoist.

COMMAND

SIGNAL

PILOT

CONTROL

PRESSURE

PCP

EDC

LINE LEGEND (FOR ALL SCHEMATICS)

CASE RETURN PRESSURE HYDRAULIC

CONTROL OR PILOT PRESSURE HYDRAULIC, REGULATED AIR

LOW-PRESSURE HYDRAULIC, SIGNAL ELECTRICAL, EXHAUSTED AIR

NEGATIVE ELECTRICAL (GROUND)

HIGH-PRESSURE HYDRAULIC, POSITIVE ELECTRICAL, MANIFOLD AIR

POSITION

SWASHPLATE

HIGH-PRESSURE SIDE

MOTOR

HYDRAULIC

PUMP

HYDRAULIC

DRUM

CONTROLLER (PC)

MANIFOLD

SUCTION

PUMP

CHARGE

LOW-PRESSURE SIDE

FEEDBACK

FEEDBACK

PRESSURE

(MOTOR STROKE)

CONTROL SIGNAL

(PUMP STROKE)

CONTROL SIGNAL

CONTROL

DISPLACEMENT

ELECTRONIC

HANDLE

CONTROL

PIPING

HYDRAULIC

PROGRAMMABLE

HANDLE

RF-01

HYDRAULIC SUCTION MANIFOLD LINE

NOT ACTIVE LINE OR CIRCUIT

SPEED SENSOR

FIGURE 1-10

Loading...

Loading...