HOISTS 2250 SERVICE/MAINTENANCE MANUAL

5-12

Published 11-06-15, Control # 040-13

- Readjust brake when 2-1/16 in (52 mm) is

reached.

g. If proper dimension is not obtained, turn off drum

park to release brake for drum being serviced.

h. Tighten band adjusting nut one to two flats at a time.

i. Repeat step 6f

until proper dimension is obtained.

j. Turn off drum park for drum being serviced. Drum

parking brake will release.

k. Check for clearance between brake lining and drum

flange:

- Grasp brake band at band adjusting nut. Band

should move back and forth freely by hand.

- As a further check, drum should turn freely

when load line is pulled by hand (clutch and

parking brake released). If drum does not turn

freely by hand and band is loose, clutch may

not be releasing. See Drum Clutch Inspection

and Adjustment topic in this section.

- If necessary, loosen jam nut at band supports

(Figure 5-7

). Turn adjusting nuts in required

direction to provide clearance between lining

and drum flange. Securely tighten jam nuts to

lock adjustment.

l. For independent drum drive, repeat steps 6d

through 6k for brake on opposite side.

Dimension measured in step 6f

must be identical for

each brake on drum to provide balanced braking.

7. Band adjustment is now complete. Select and confirm

desired operating mode.

Treadle Valve Checks

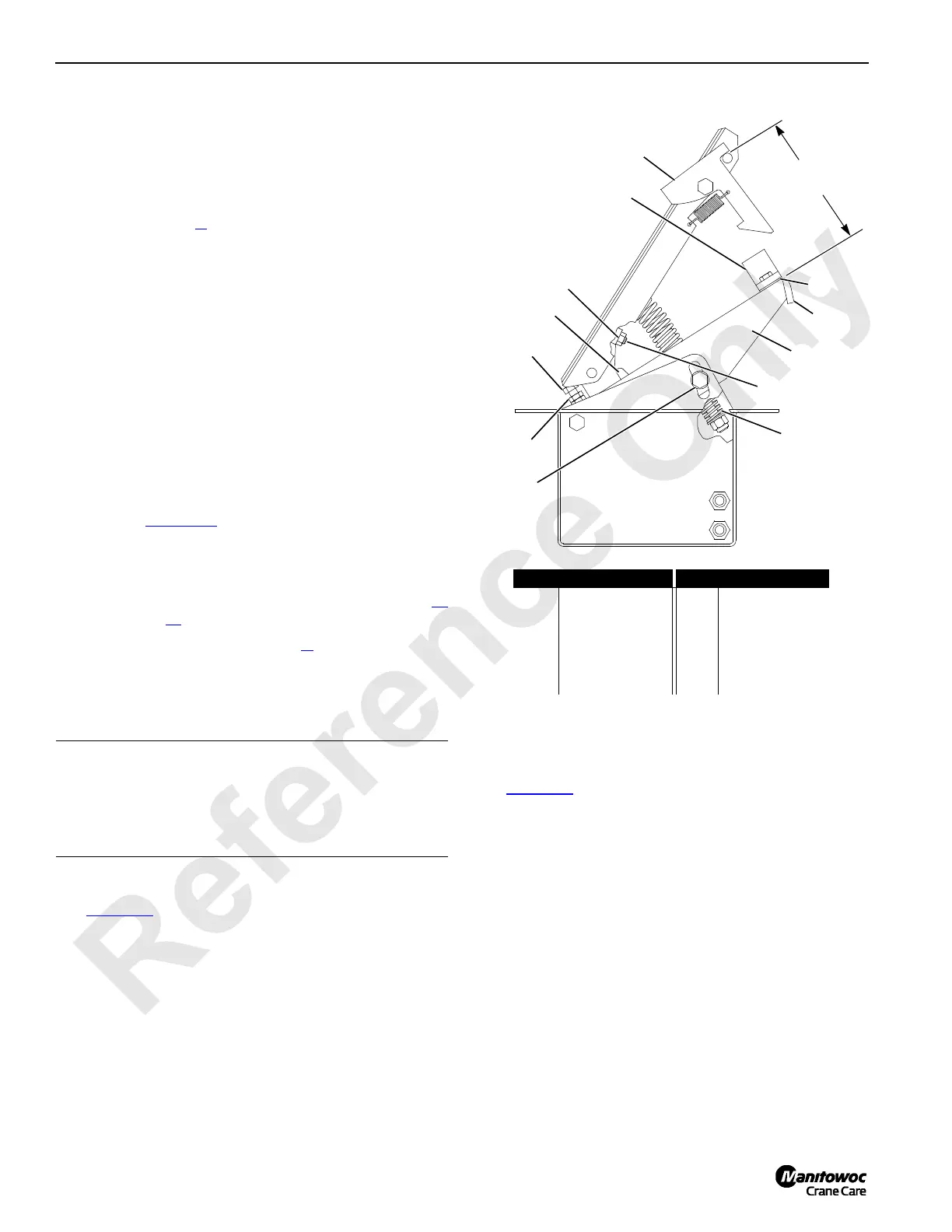

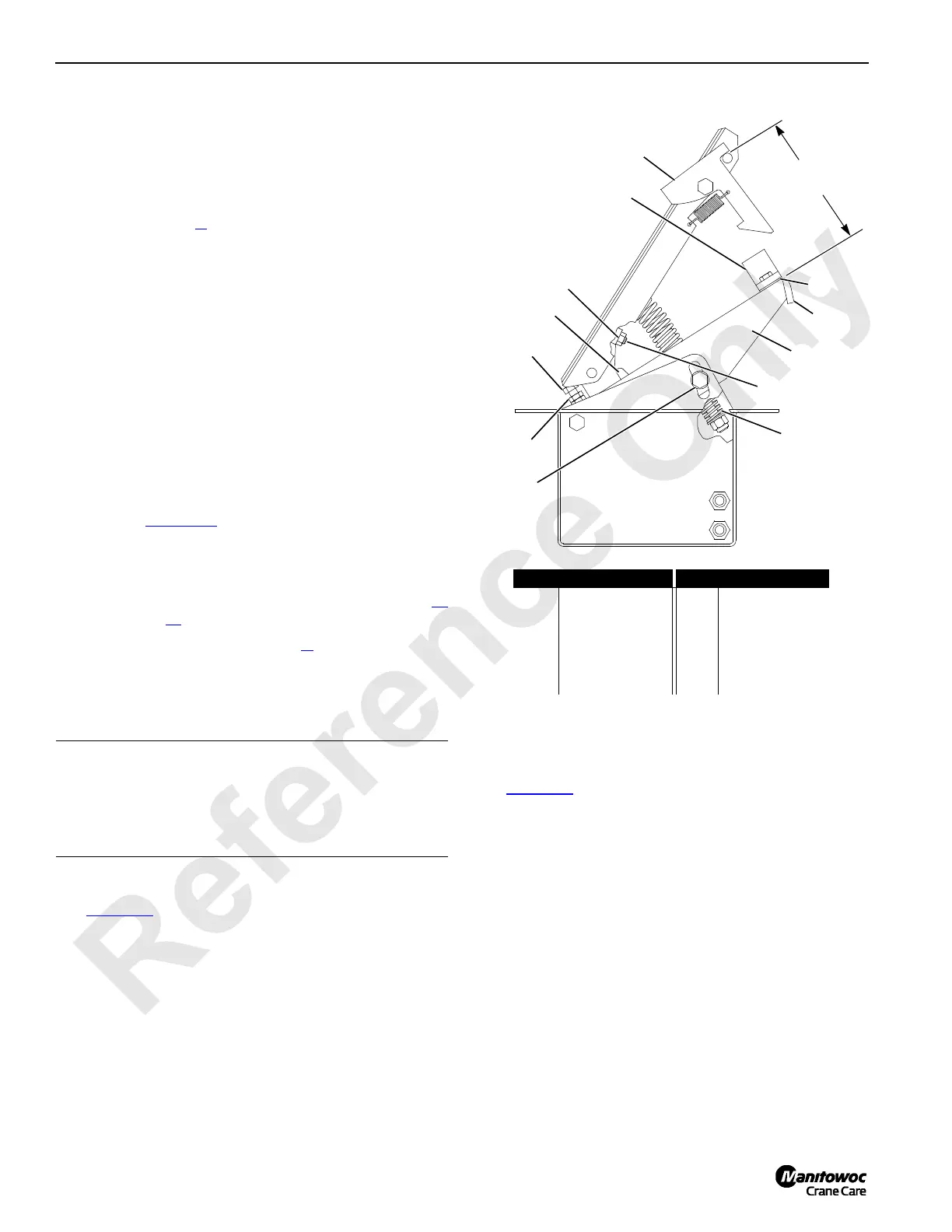

See Figure 5-9 for the following procedure.

1. Check each pedal latch and latch bar for wear. Pedal

latch must hold pedal down in fully applied position.

2. Connect 0 to150 psi (0 to 10,3 bar) air pressure gauge to

in and out ports of valve:

• Air pressure at in port should be 120 to 132 psi (8,3

to 9,1 bar).

• Air pressure at out port should modulate from 0 to

75 psi (0 to 5,2 bar) as pedal is slowly depressed

and then go to 120 to 132 psi (8,3 to 9,1 bar).

Treadle Valve Adjustments

See Figure 5-9 for the following procedure.

1. Lower load for treadle valve being adjusted to

ground so load line is slack.

2. Adjust pedal to desired height:

a. Latch pedal down.

b. Loosen four cap screws (1).

c. Move valve support (2) to desired height.

d. Securely tighten cap screws.

3. Adjust spring (3) for a 2-7/8 in (73 mm) preload.

4. Install shims (4) under bumper (5) so pedal compresses

bumper 1/32 in (0,8 mm) when pedal is latched.

5. Adjust valve (6) as follows:

a. Release brake pedal to fully raised position.

CAUTION

Drum Flange Damage!

Brake lining must not rub against drum flange when brake

is released. Otherwise, lining will overheat, possibly

resulting in cracks in drum flange.

FIGURE 5-9

5-1/4 in

(133 mm)

IN

OUT

B225

Item Description Item Description

1 Cap Screw 7 Jam Nut

2 Valve Support 8 Set Screw

3Spring 9Jam Nut

4Shims 10Screw

5 Bumper 11 Pedal Latch

6 Valve 12 Latch Bar

1

2

3

4

5

6

7

8

9

10

11

12

Loading...

Loading...