Manitowoc Published 11-06-15, Control # 040-13 5-27

2250 SERVICE/MAINTENANCE MANUAL HOISTS

• End Attachments — the point where a fitting is

attached to the wire rope or the point where the wire

rope is attached to the drum.

• Abuse Points — the point where the wire rope is

subjected to abnormal scuffing and scraping.

Inspect all rope which can be reasonably expected to be in

use during operation for obvious damage which poses an

immediate hazard, such as the following:

• Rope distortion such as kinking, crushing, un-stranding,

bird caging, main strand displacement, and core

protrusion.

Loss of rope diameter and unevenness of the outer

strands indicate that the rope should be replaced.

• Corrosion (clean and lubricate)

• Broken or cut strands

• Broken wires (see Periodic Inspection topic for

additional information)

• Core failure in rotation resistant rope (indicated by lay

lengthening and reduction in diameter).

Periodic Inspection

The periodic inspection interval must be determined by a

qualified inspector and be based on the following factors:

• Expected rope life as indicated by the rope manufacturer

or past experience as determined by a qualified

inspector

• Severity of environment in which the rope is operated

• Size, nature, and frequency of lifts

• The rope’s exposure to shock loading and other abuse

• Rope maintenance practices

The periodic inspection must be performed at least

annually.

During the periodic inspection, the entire length of wire rope

must be inspected for the following types of damage. Any

damage found must be recorded and a determination made

as to whether continued use of the rope is safe.

• All points listed under frequent inspection

• Reduction in rope diameter below the nominal diameter

caused by loss of core support, internal or external

corrosion, or wear of the outside wires

• Severely corroded or broken wires at end attachments

• Severely corroded, cracked, bent, worn, or improperly

applied end attachments

Inspecting Rope Not In Regular Use

Wire rope must be given a complete inspection if it has been

idle for a month or more due to shutdown or storage of the

crane on which the rope is installed. The inspection must be

performed by a qualified inspector looking for the damage

identified under both Frequent and Periodic Inspection.

Replacing Wire Rope

The final decision as to when a wire rope should be replaced

is the responsibility of the qualified inspector. Discovery of

any of the following conditions is sufficient reason for

questioning a wire rope’s safety and for replacing it.

Wire Rope Diameter

Measure and record the diameter of a new wire rope after

initial loading for comparison with future inspections. A

reduction in rope diameter is often the first outward sign that

the wire rope core is damaged. When reduction in diameter

is noted, the rope must be removed from service.

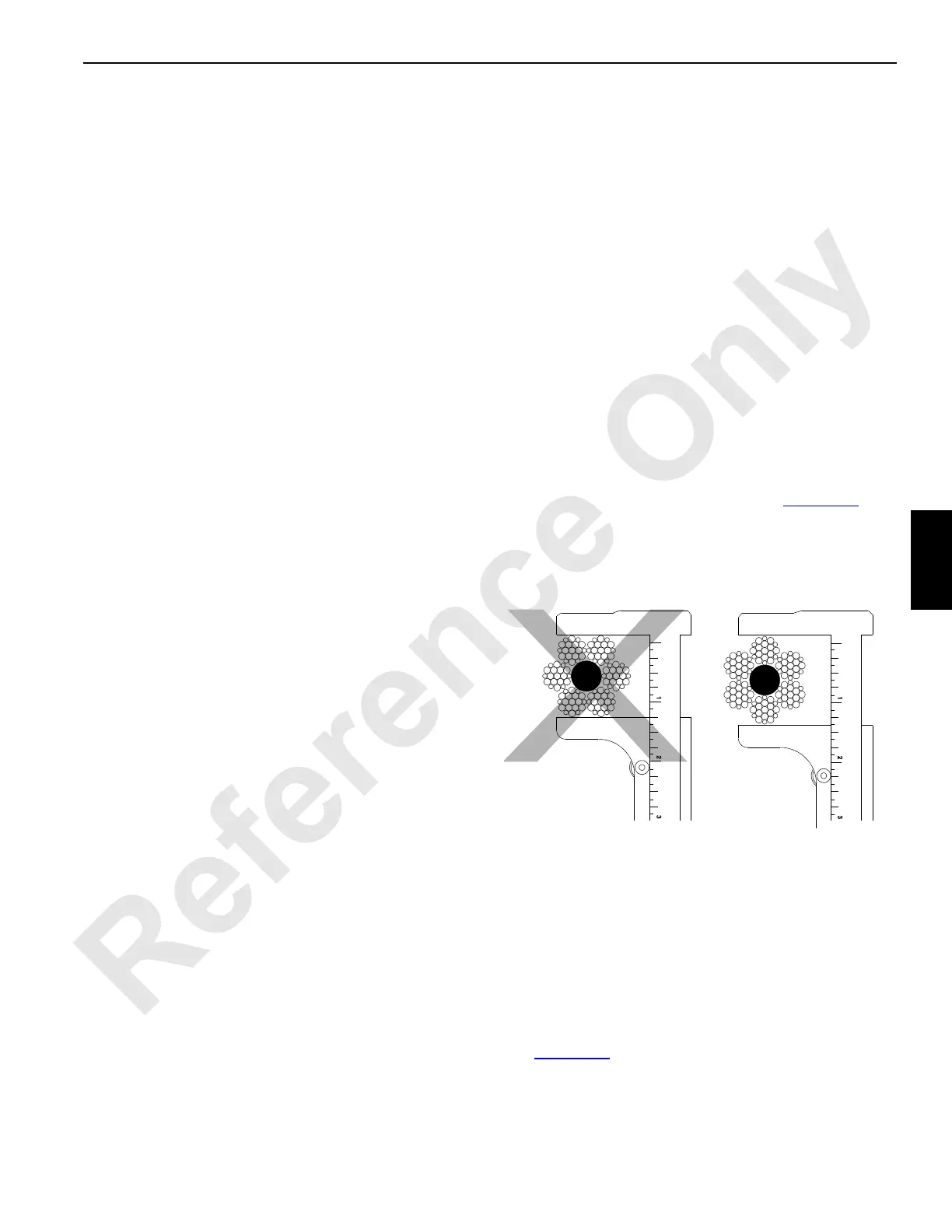

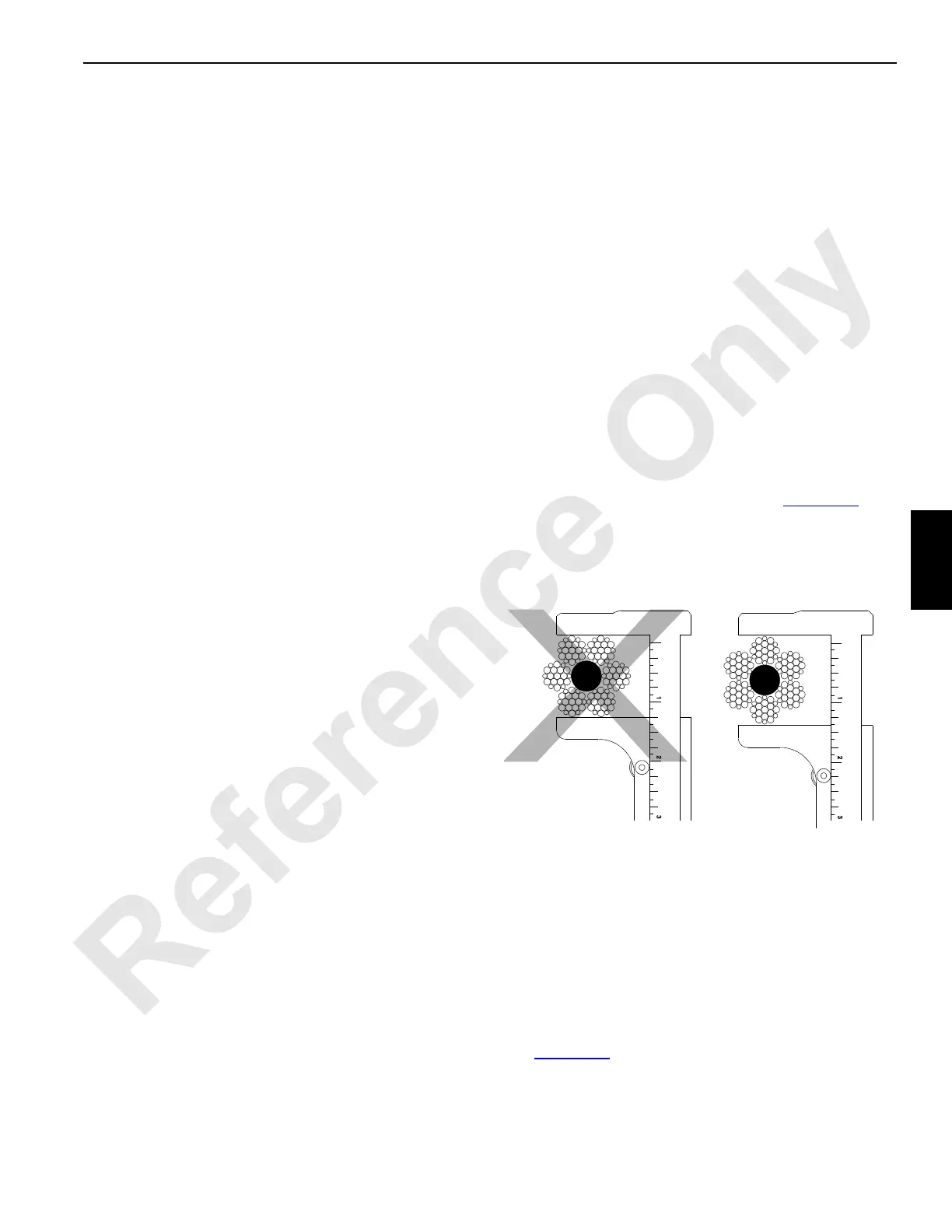

Measure the rope’s diameter across crowns of the strands so

the true diameter is measured as shown in Figure 5-22

.

Wire rope must be taken out of service when the

reduction from its nominal diameter is more than 5

percent.

Broken Wires

Thoroughly clean the wire rope so breaks can be seen.

Relax the rope, move it off “pick-up points,” and flex it as

much as possible. Use a sharp awl to pick and probe

between wires and strands, lifting any wire which appears

loose or moves excessively.

Wire rope shall be taken out of service when it has the

following number of broken wires:

See Figure 5-23

for an explanation of lay length.

FIGURE 5-22

WRONG

A925

RIGHT

Loading...

Loading...