INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-36

Published 11-06-15, Control # 040-13

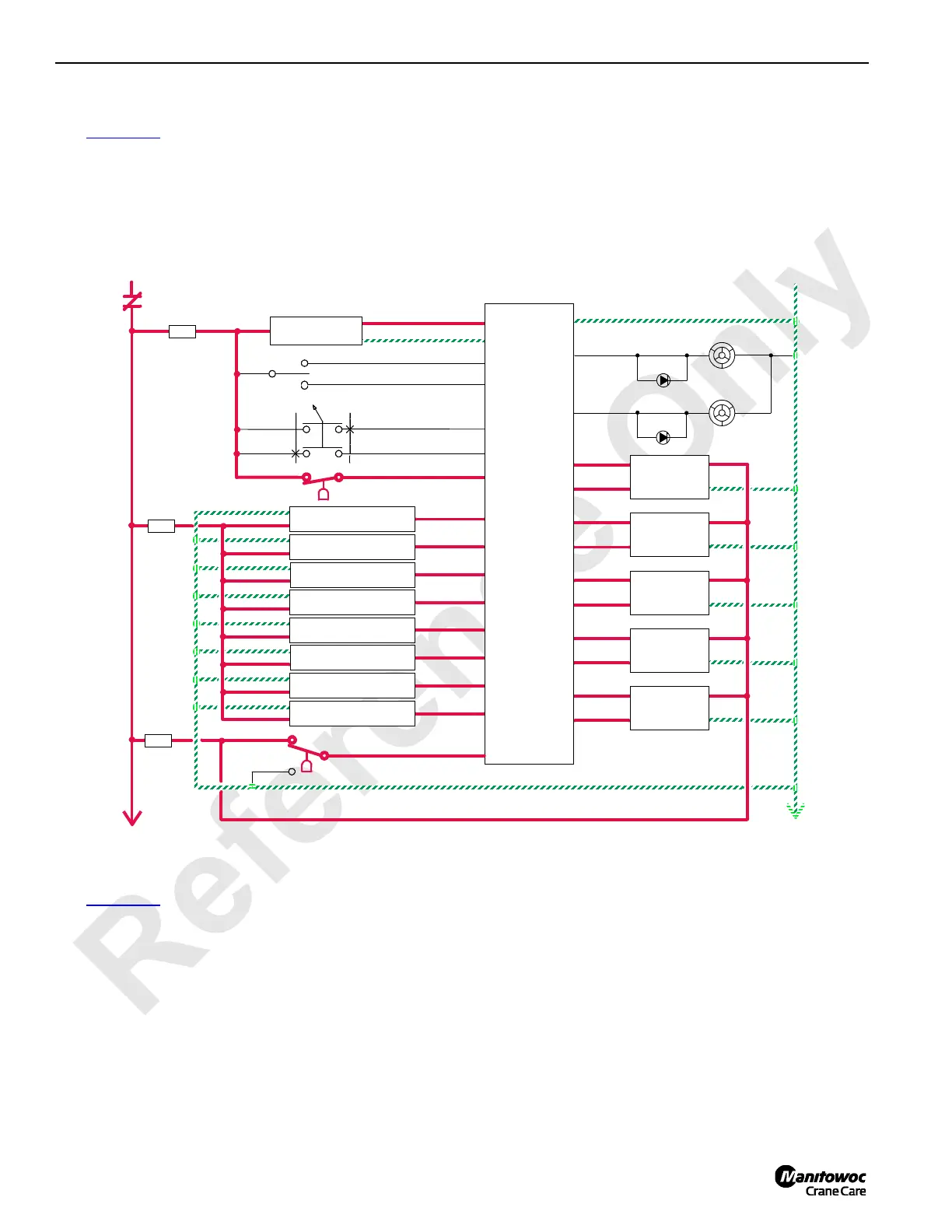

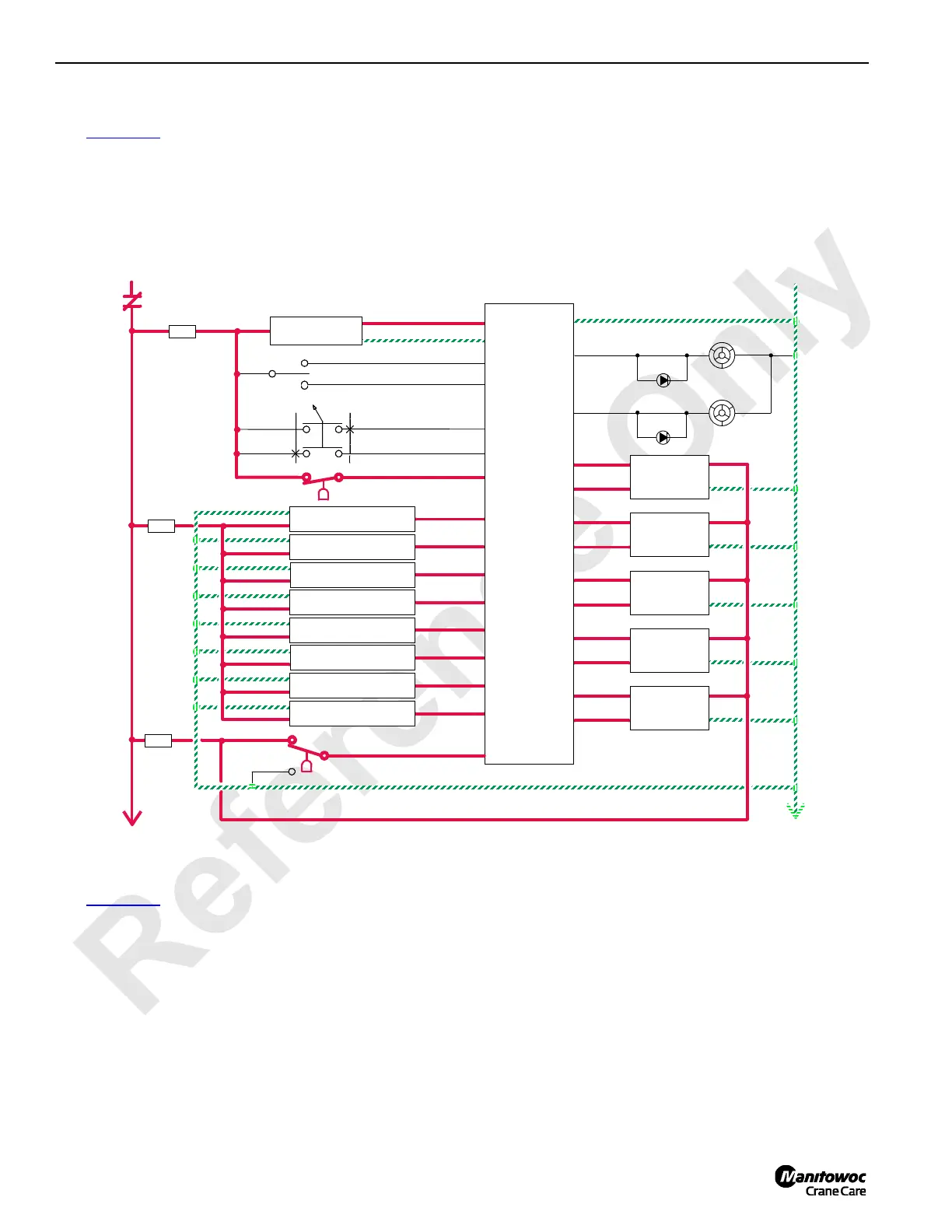

Pressure Senders and Speed Sensors

See Figure 1-18 for the following procedure.

Pressure senders monitor drum system pressures, load

drum charge pressure, right/left travel system pressure,

swing right/left system pressure. The PC receives input

hydraulic pressure information from each system pressure

sender. Pressure senders provide information on the

required load holding pressure for load drums, boom hoist

drum, or luffing hoist drum.

Drum speed sensors on drum shafts or flanges detect speed

and direction of drum movement. The PC receives this

information as two out-of-phase square wave voltages that

are converted to “counts”. The PC compares control handle

voltage with pump output to determine when to vary pump

stroke.

Limit Switches and Faults

See Figure 1-19 for the following procedure.

When operating, all limit switches are closed, sending an

input voltage to the PC. If a limit switch is tripped, the PC

sends a 0 volt output to system pump EDC and brake

solenoid. System pump de-strokes and system brake

solenoid valve shifts to apply brake. Move component in the

opposite direction away from limit to correct the problem.

The limit bypass switch allows crane to be operated beyond

the limits for crane setup or maintenance only. For example,

to add wire rope on load drum or to remove wire rope from

load drum after an operating limit is enabled. The jib up limit

bypass switch allows the jib maximum up limit to be

bypassed when boom or luffing jib is lowered to ground.

Hydraulic Brake Systems

Travel, swing, boom hoist, and luffing jib hoist brakes are

spring set and hydraulically released. The operator enables

brake operation by placing selected brake switch in off

position. The PC releases swing brake and swing lock

immediately when swing brake switch is placed in off position

(Past Production). The PC controls release of other brakes

with control handle movement.

LOW AIR SWITCH

WB-20

WD-20

WD-19

8D8

WD-11

WB-24

SELECT

CONFIRM

CRANE MODE

8T

8

0

5A

0

8

WB-26

WB-33DOWN SCROLL

UP SCROLL

WA-26

WA-28

WA-23

WA-27

WA-24

WA-22

WA-19

WA-25

K1

RF-10

F10

WE-02

WE-01

8E

0

FRONT

(DRUM 1)

SPEED

SENDER

F

A

B

D

F12

PRESSURE SENDER

SWING LEFT

PRESSURE SENDER

SWING RIGHT

PRESSURE SENDER

LEFT TRAVEL

PRESSURE SENDER

RIGHT TRAVEL

PRESSURE SENDER

BOOM HOIST

PRESSURE SENDER

LOAD DRUM SYSTEM

PRESSURE SENDER

LOAD DRUM CHARGE

PRESSURE SENDER

LUFFING HOIST

8E

8

F11

SYSTEM FAULT

ALARM

WC-35

WC-34

OPERATING LIMIT

LIGHT

ALARM

LIGHT

WE-04

WE-03

8E

0

RIGHT REAR

(DRUM 2)

SPEED

SENDER

F

A

B

D

WE-06

WE-05

8E

0

LEFT REAR

(DRUM 3)

SPEED

SENDER

F

A

B

D

WD-06

WD-05

8E

0

BOOM HOIST

SPEED

SENDER

F

A

B

D

WD-02

WD-01

8E

0

LUFFING JIB

SPEED

SENDER

F

A

B

D

D

(DRUM 4)

(DRUM 5)

PROGRAMMABLE

CONTROLLER

HYD VACUUM SWITCH

WA-31

DIGITAL DISPLAY

5A

5A

5A

FIGURE 1-18

Loading...

Loading...