HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-28

Published 11-06-15, Control # 040-13

4. Wash all parts in soap and water and dry.

5. For the Type A filter, wash the element in alcohol and

blow it out from the inside with air. For the Type B filter,

discard the element.

6. Inspect all parts for damage and replace as necessary.

7. See Figure 2-31

and reassemble the filter. Tighten all

threaded parts securely.

8. If disconnected, reconnect the air lines to the proper

ports of the filter. Use pipe-thread sealant or tape

sparingly and apply only to the male threads.

NOTE: The top of the Type A filter is marked in and out to

identify the ports. Connect the line from the tank to

the in port.

The top of the Type B filter has an arrow to identify

direction of flow. The arrow must point away from

the air tank.

9. Close all drain valves and open all shut-off valves.

10. Build air system pressure to the normal operating range

and check the filter for leaks.

Automatic Drain Valve Operation

NOTE: The automatic drain valve is not used on all filter

installations.

The automatic drain valve contains a float. When the liquid in

the valve body rises to the level of the float, the float rises to

open a needle valve. This action allows the liquid to drain. Air

pressure then re-seats the float, and the cycle repeats.

AIR SYSTEM DE-ICER MAINTENANCE

Operation

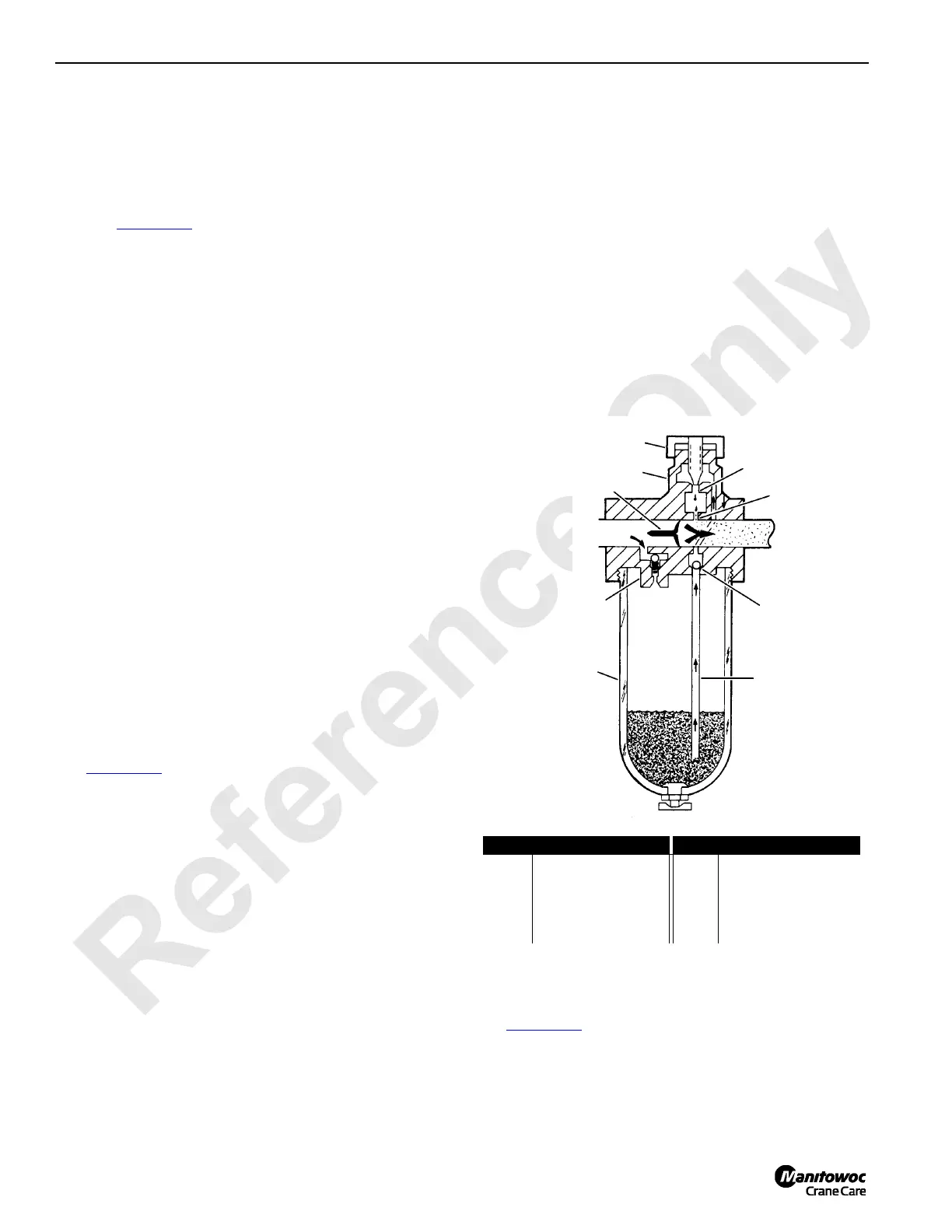

See Figure 2-32 for the following procedure.

Air system de-icer meters anti-freeze into the air line only

when there is air flow through the de-icer. Air flowing through

the de-icer passes around flow sensor (1) to the downstream

system. Inlet pressure is admitted to the reservoir through

check (charge) valve (2). When air is flowing, a small

pressure drop occurs across the flow sensor. The outlet

(lower) pressure is sensed in sight feed dome (3) through

nozzle passage (4). This establishes a pressure drop across

metering orifice (5) and anti-freeze at inlet pressure flows

upward through siphon tube (6) into the sight feed dome

where it drips into the nozzle passage and then into the de-

icer throat. Adjusting knob (7) controls the drip rate. Anti-

freeze drops are atomized by the high velocity air flowing

past the flow sensor and are carried downstream. Check ball

(8) prevents back flow of anti-freeze into the reservoir during

periods of no flow.

Flow sensor functions as a variable restriction in the throat of

the de-icer to produce a pressure drop of up to 5 psi (0,3 bar)

that is proportional to the rate of air flow through the de-icer.

These variations in outlet pressure, sensed in the sight-feed

dome, cause a like variation in the pressure drop across the

metering orifice as a function of air flow. Thus, for a given

drip rate setting at some average air flow, a lower air flow will

cause a proportionally higher drip rate.

Charge valve (2) controls the rate of reservoir pressurization

and allows rapid de-pressurization for refilling without

shutting off the air pressure. When anti-freeze plug is

loosened, a bleed orifice is exposed which immediately

reduces the reservoir pressure. This pressure drop causes

the charge valve to close and restrict air flow into the

reservoir to eliminate blow-back when adding anti-freeze.

When the fill plug is replaced, the reservoir re-pressurizes

through the charge valve at a nominal rate. The charge valve

opens fully when inlet pressure is reached.

Adjusting

See Figure 2-32 for the following procedure.

Turn adjusting knob (7) counterclockwise to increase the

drip rate or clockwise to decrease the drip rate (1 to 3 drops

per minute is usually sufficient). Drip rate adjustments should

only be made under a steady flow condition. Once

S115

FIGURE 2-32

IN

OUT

5

6

7

8

1

3

2

4

9

Item Description Item Description

1 Flow Sensor 6 Siphon Tube

2 Check Valve (charge) 7 Adjusting Knob

3 Sight Feed Dome 8 Check Ball

4 Nozzle Passage 9 Reservoir

5 Metering Orifice

Loading...

Loading...