Manitowoc Published 11-06-15, Control # 040-13 7-9

2250 SERVICE/MAINTENANCE MANUAL POWER TRAIN

b. Loosen seal in all four corners of filter one at a time

by pulling it straight out.

c. It may be necessary to loosen seal along edges of

element in a similar manner.

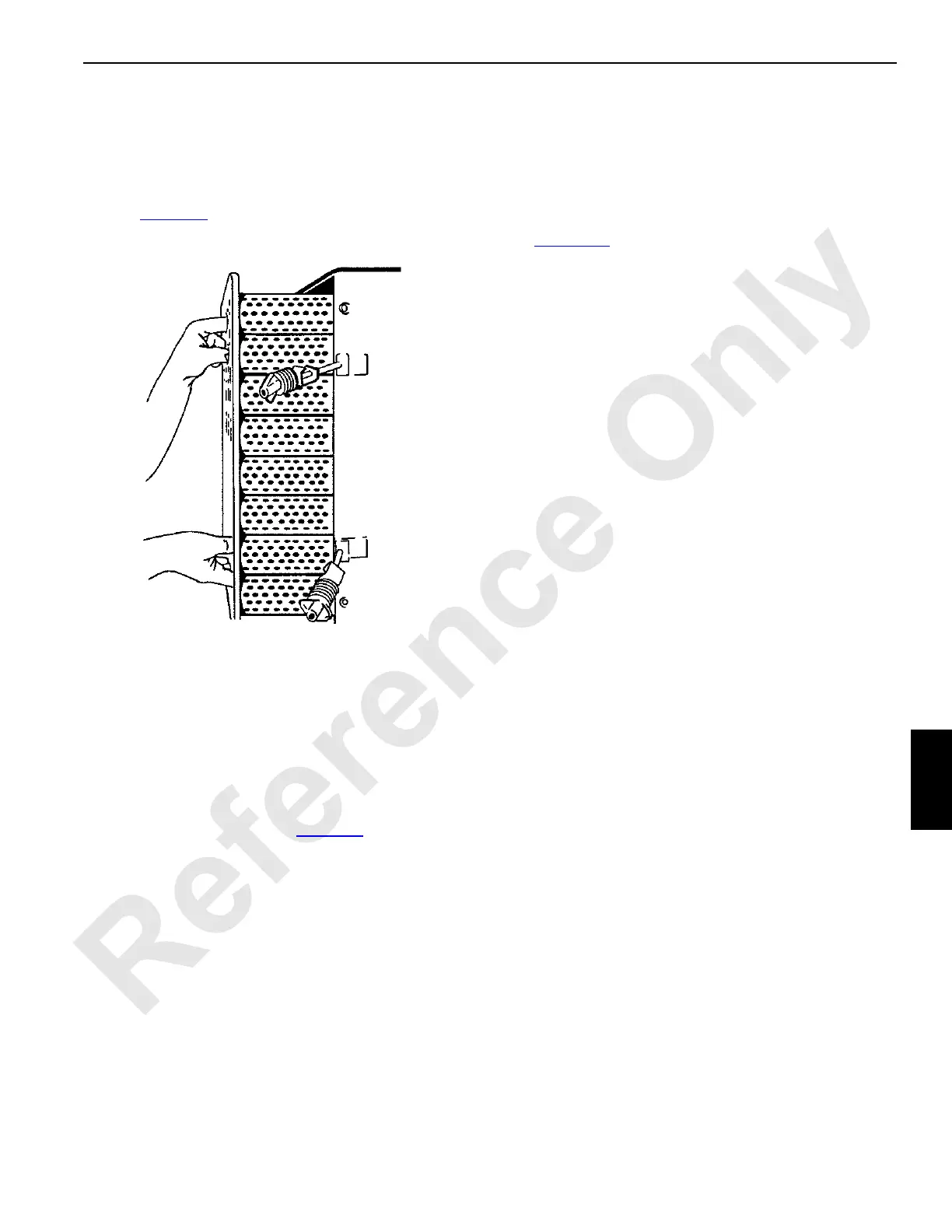

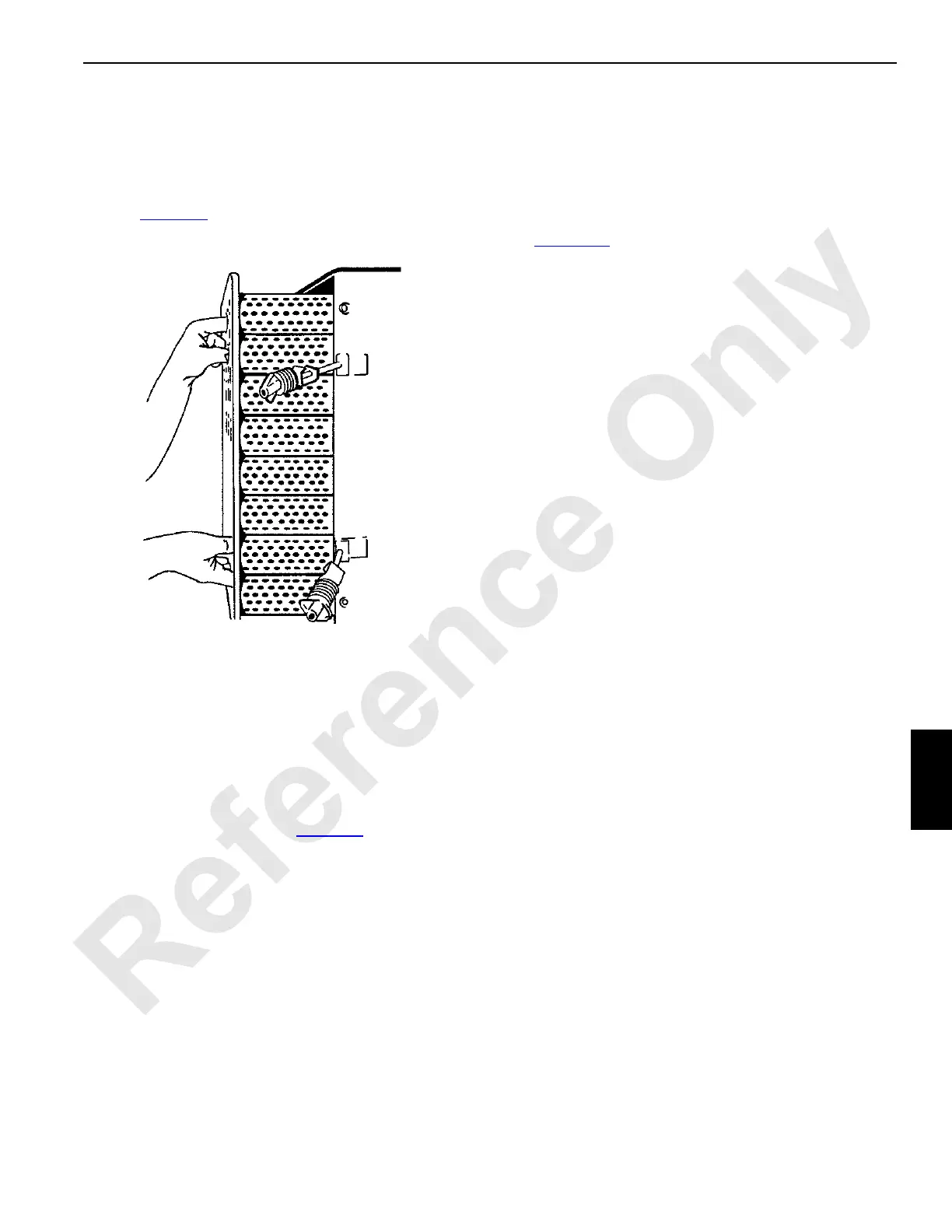

d. After seal is loose, grasp filter as shown in

Figure 7-9

and pull filter straight out and slightly up

so filter clears edges of housing.

3. Clean inside of housing with a damp cloth. Make sure

housing is free of all foreign matter.

Use care not to allow foreign matter to enter tubing

in air inlet hole to engine.

4. Wipe off face of pre-cleaner. If desired, pre-cleaner can

be steam cleaned.

5. Install new filter, as follows:

a. Grasp filter as shown in Figure 7-9

.

b. Insert filter in housing. Avoid hitting element tubes

against sealing flanges on edges of housing.

c. Make sure filter is seated properly in housing. Firmly

press all edges and corners of element into place to

form a positive seal against flanges in housing.

Do not pound filter in place.

6. Assemble pre-cleaner to housing with clamps. Tighten

nuts in a crisscross manner to 70 in-lbs (8 N•m).

7. Check that ejector valve is installed in dust bin of pre-

cleaner.

8. Reset filter indicator.

ENGINE AIR CLEANER MAINTENANCE —

TIER 4 ENGINE

See Figure 7-10 for the following procedure.

The air cleaner is mounted and fastened to the engine air

intake (6) with a rubber elbow reducer (5), clamps (3), tubes

(2) and reducer (4). Servicing the air cleaner is an important

function because:

• Clogged air cleaner filters will prevent adequate air flow

to the engine, causing poor starting and increased

exhaust emissions.

• An improperly installed or damaged air cleaner can

allow dirty air to be drawn directly into the engine.

Either condition can cause engine damage.

Inspection

To maintain engine protection and filter service life, inspect

the following areas at regular intervals:

Daily

Check service indicator (8) with engine running. The

indicator gives a visual indication when it is time to replace

the filters.

• A yellow flag in the indicator window (8a) extends as the

filters become plugged. Replace filters when the

yellow indicator reaches the red zone at the end of

the indicator.

• The yellow flag remains locked in place after the engine

is stopped. When the filters are replaced, push button

(8b) in to reset the indicator.

Weekly

1. Inspect rubber reducers (4 and 5) between air cleaner

and engine for cracks or other damage which might

allow unfiltered air to enter the engine. Replace worn or

damaged parts.

2. Check housing (1e) for dents or other damage that may

allow unfiltered air to enter engine. Replace housing if

damaged.

3. Check for loose clamps (3). Tighten if necessary.

4. Inspect engine intake (6) for obstructions. Clean as

required.

Loading...

Loading...