TROUBLESHOOTING 2250 SERVICE/MAINTENANCE MANUAL

10-48

Published 11-06-15, Control # 040-13

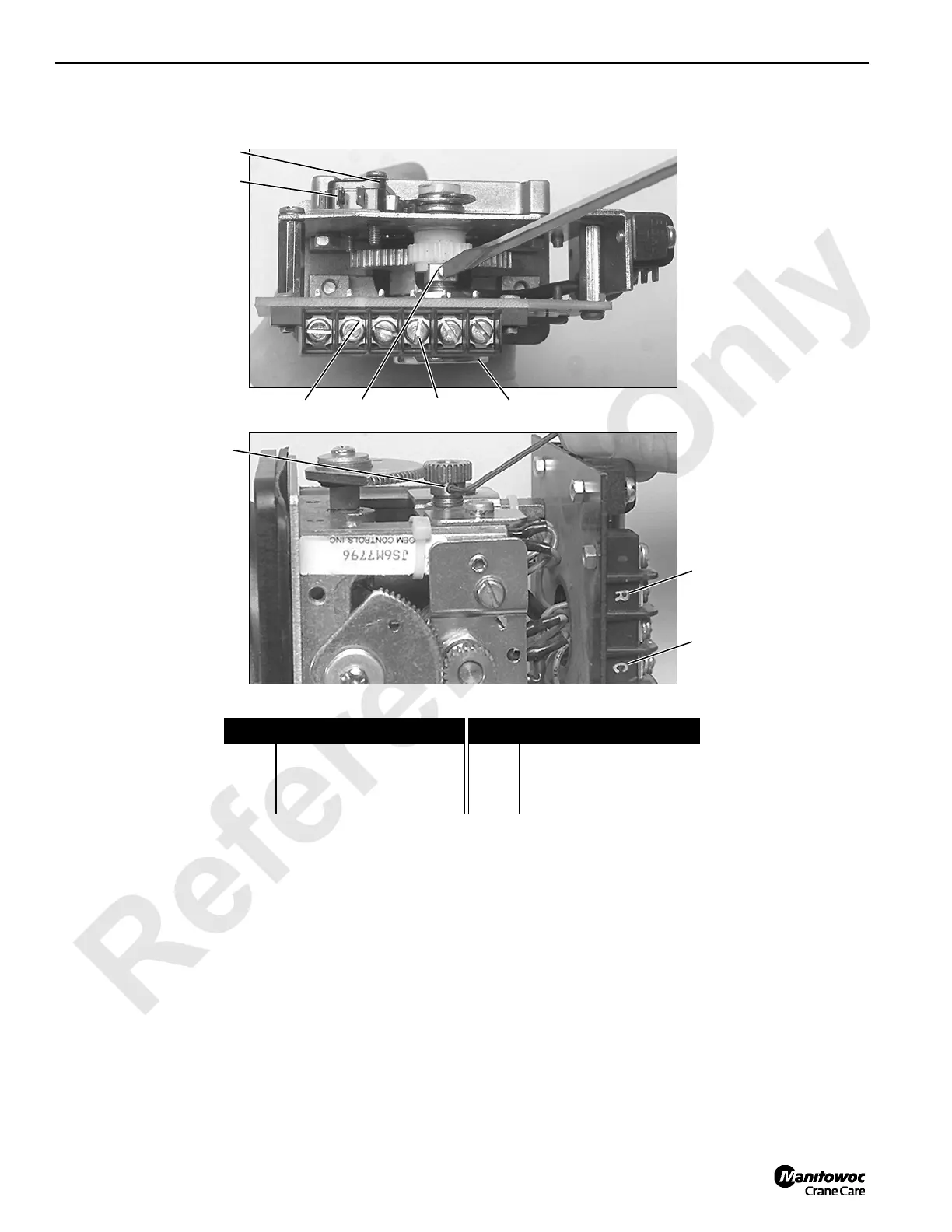

Test 14 — Adjusting the Control Handle Potentiometer

An unusual reaction to a control handle movement may

indicate a misalignment or handle potentiometer. Adjusting a

single axis or double axis control handle requires aligning the

handle and potentiometer in the neutral position. Neutral is

the position where 5 volts DC is present.

To check single axis controller:

• Engine must be off and power on, with all brakes and

locks engaged.

• Connect a jumper wire between the normally open

terminal on the neutral switch and terminal “C” on the

handle terminal block.

• Connect the positive lead of a digital multi-meter to

terminal “C”.

• Connect the negative lead on a grounded crane

component or on terminal “R”.

• Loosen the slotted set screw (item 4) and allow handle

to return to neutral position.

• Retighten slotted set screw and move handle until a

reading of 5 volts DC is obtained.

• Holding the handle in the 5-volt position, loosen the

slotted set screw (item 4).

• Allow handle to return to neutral position.

• Retighten slotted set screw.

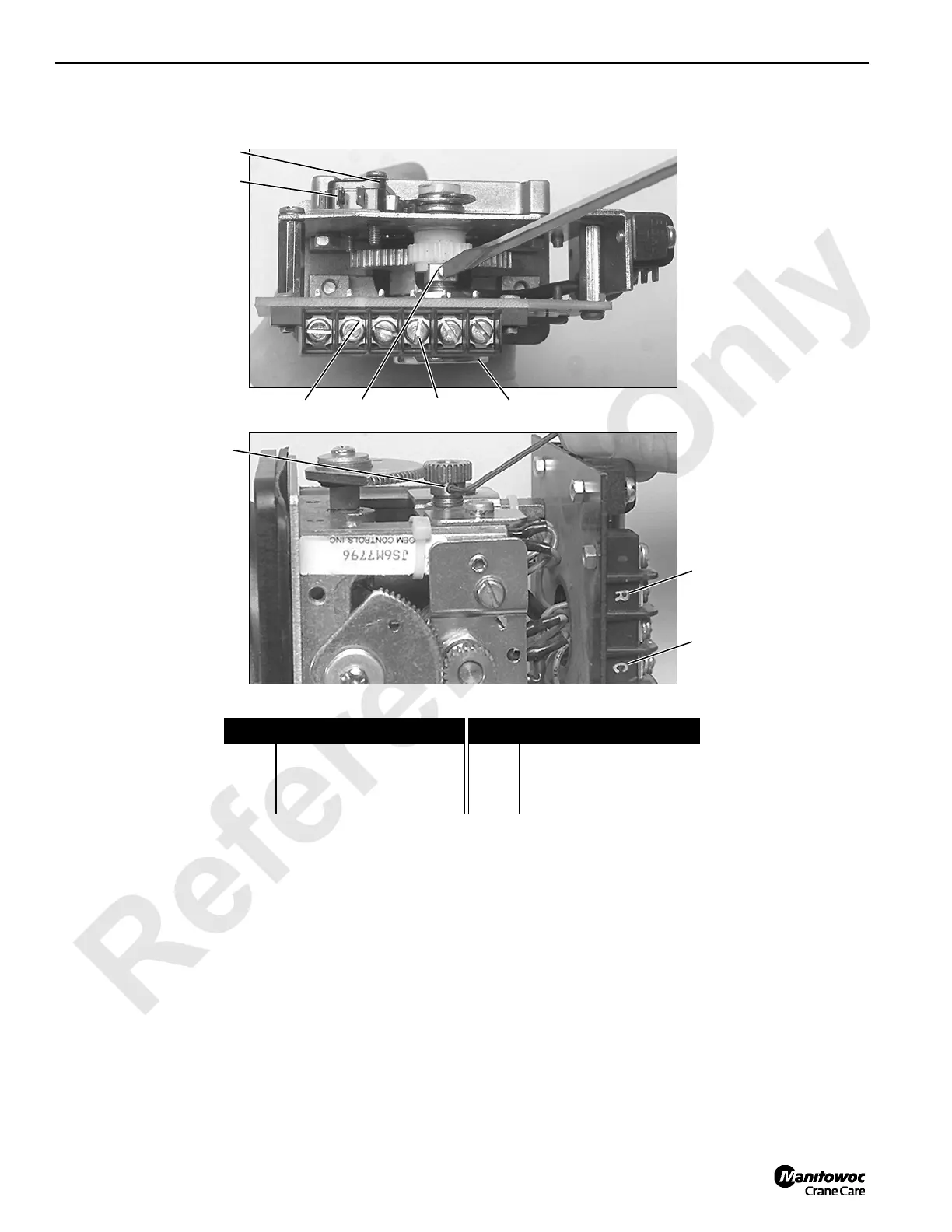

Double axis control handle adjustment is the same, except

the 2 socket set screws (item 7) on gear collar are loosened.

Item Description Item Description

1

2

3

4

Neutral (snap) switch

Jumper connection (N/O)

Ground terminal “R”

Slotted set screw

5

6

7

Center Terminal “C”

Potentiometer

Socket set screw (2)

6

P1525

P1526

543

1

2

7

3

5

Double Axis

Controller

Single Axis

Controller

Loading...

Loading...