Manitowoc Published 11-06-15, Control # 040-13 1-95

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

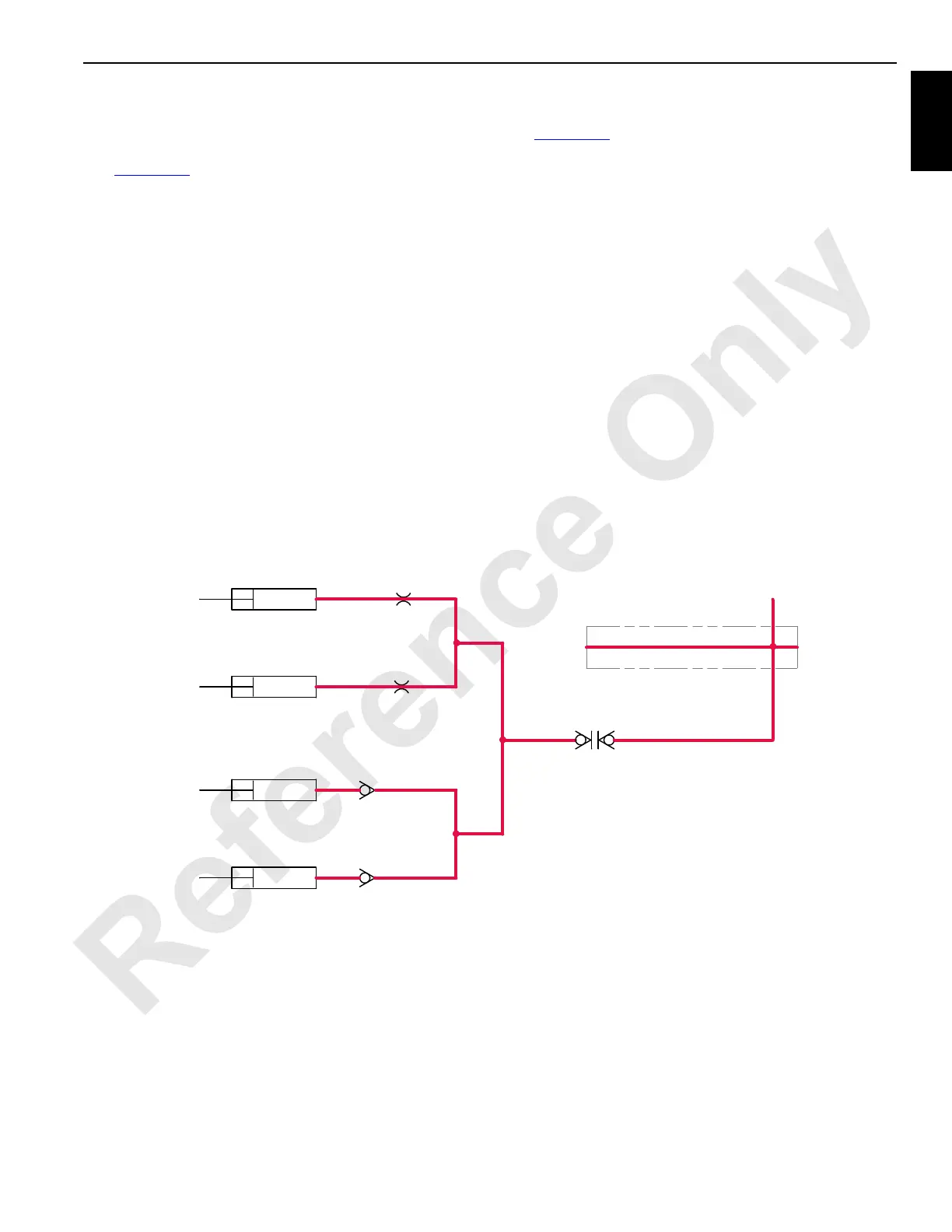

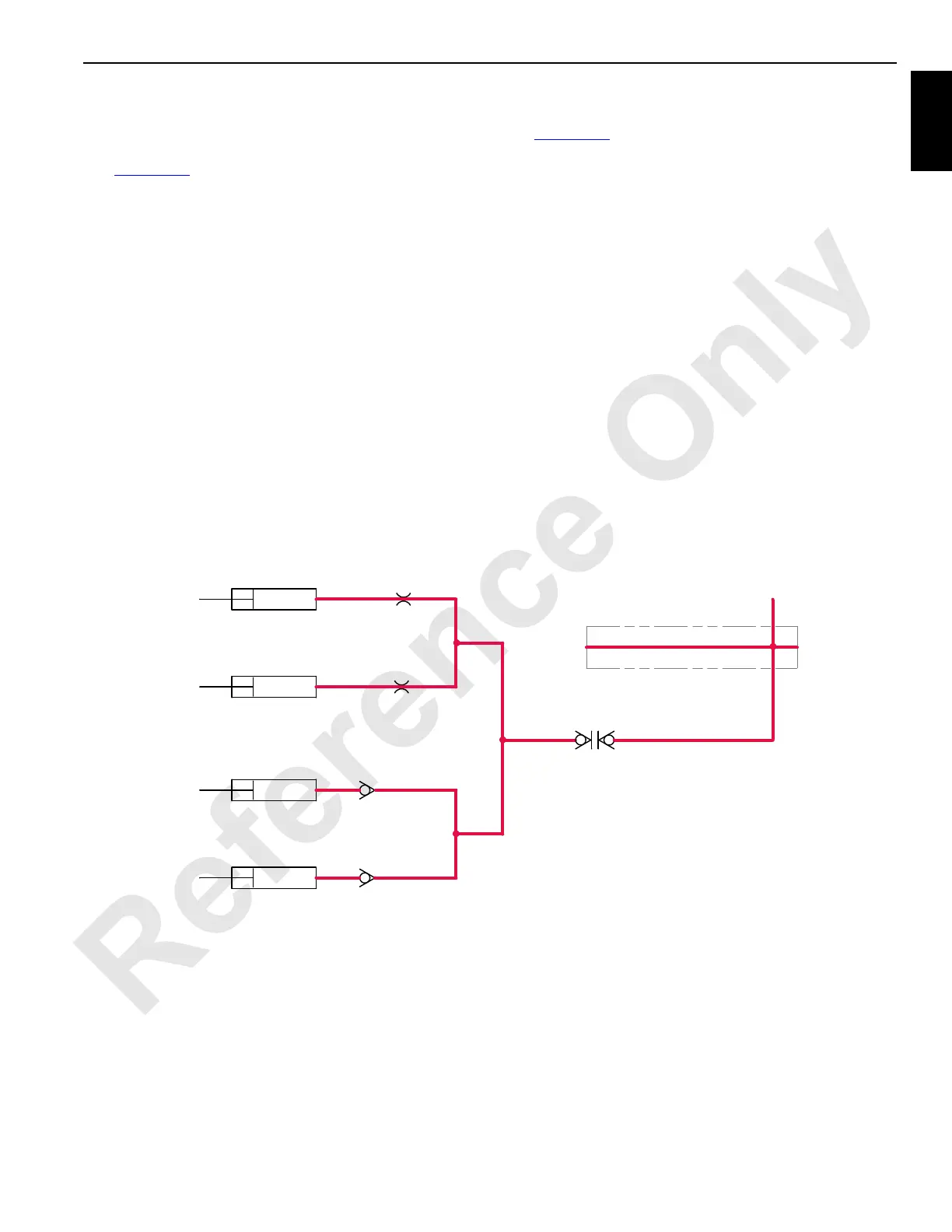

Mast Stop Raising And Boom Stop

Mast Stop Raising Cylinders

See Figure 1-60 for the following procedure.

The mast stop raising cylinders pneumatically position the

physical mast stops. Once the physical mast stops are raised

at assembly, the mast stop raising cylinders are pinned to

physical mast stops. See Assembly/Disassembly topic in

Section 4 of MAX-ER 2000 Operator Manual for instructions

on mast assembly/disassembly.

When the engine is started, pressurized air at 120 to 132 psi

(8.2 to 9,1 bar) from crane’s engine compressor provides air

to operate mast stop raising cylinders. An air line from crane

manifold goes to quick disconnect at mast base. After the

quick disconnect there is a tee that splits, with one line going

to mast stop raising cylinders on mast and the other line

going to boom stop cushion cylinders on boom butt. The

mast stop raising cylinder rods extend and push mast stops

to working position. The physical mast stop ends rest on

gantry pins. A fixed restriction at piston end of each cylinder

acts as a cylinder shock cushion.

Boom Stop Cushion Cylinders

See Figure 1-60 for the following procedure.

The boom stop cushion cylinders pneumatically cushion the

boom against the mast when at or near maximum boom

angle.

When engine is started, pressurized air at 120 to 132 psi (8.2

to 9,1 bar) from crane’s engine compressor provides air to

boom stop cushion cylinders. An air line from crane manifold

goes to quick disconnect at mast base. After the quick

disconnect there is a tee that splits, with one line going to

mast stop raising cylinders on mast and the other line going

to boom stop cushion cylinders on boom butt.

If boom is raised to 80 degrees, boom-stop cylinders slow

the boom opposite movement. Check valves prevent

compressed air from escaping boom stop cylinders. Air

pressure increases in boom stop cylinders, slowing the

boom before boom stop struts contact the boom. At

approximately 90 degrees boom-stop cylinders bottom out

and boom physically stops. Orifices of boom stop cylinders

act as shock absorbers for lowered boom struts when

transporting crane.

RM-15

FROM MAIN

AIR MANIFOLD

MANIFOLD

CHECK

VALVE

CHECK

VALVE

RIGHT BOOM

STOP CUSHION

CYLINDER

LEFT BOOM

STOP CUSHION

CYLINDER

RIGHT MAST STOP

RAISING CYLINDER

LEFT MAST STOP

RAISING CYLINDER

QUICK

DISCONNECT

RESTRICTION

RESTRICTION

FIGURE 1-60

Loading...

Loading...