Manitowoc Published 11-06-15, Control # 040-13 5-11

2250 SERVICE/MAINTENANCE MANUAL HOISTS

Brake Inspection and Adjustment

1. Inspect all pins and linkage for excessive wear, and

replace parts as required. Worn pins and linkage will

make it difficult to obtain proper drum-to-lining

clearance.

2. Lubricate pins in linkage with a few drops of engine oil.

Lubricate grease fittings according to lubrication topic in

Section 9 of this manual.

3. Check linings for excessive wear. Linings normally wear

faster at dead end of brake band. Check this area first.

Brake lining is 1/2 in (12,7 mm) thick when new. Replace

lining when thinnest area has worn to 7/32 in (6 mm)

thick.

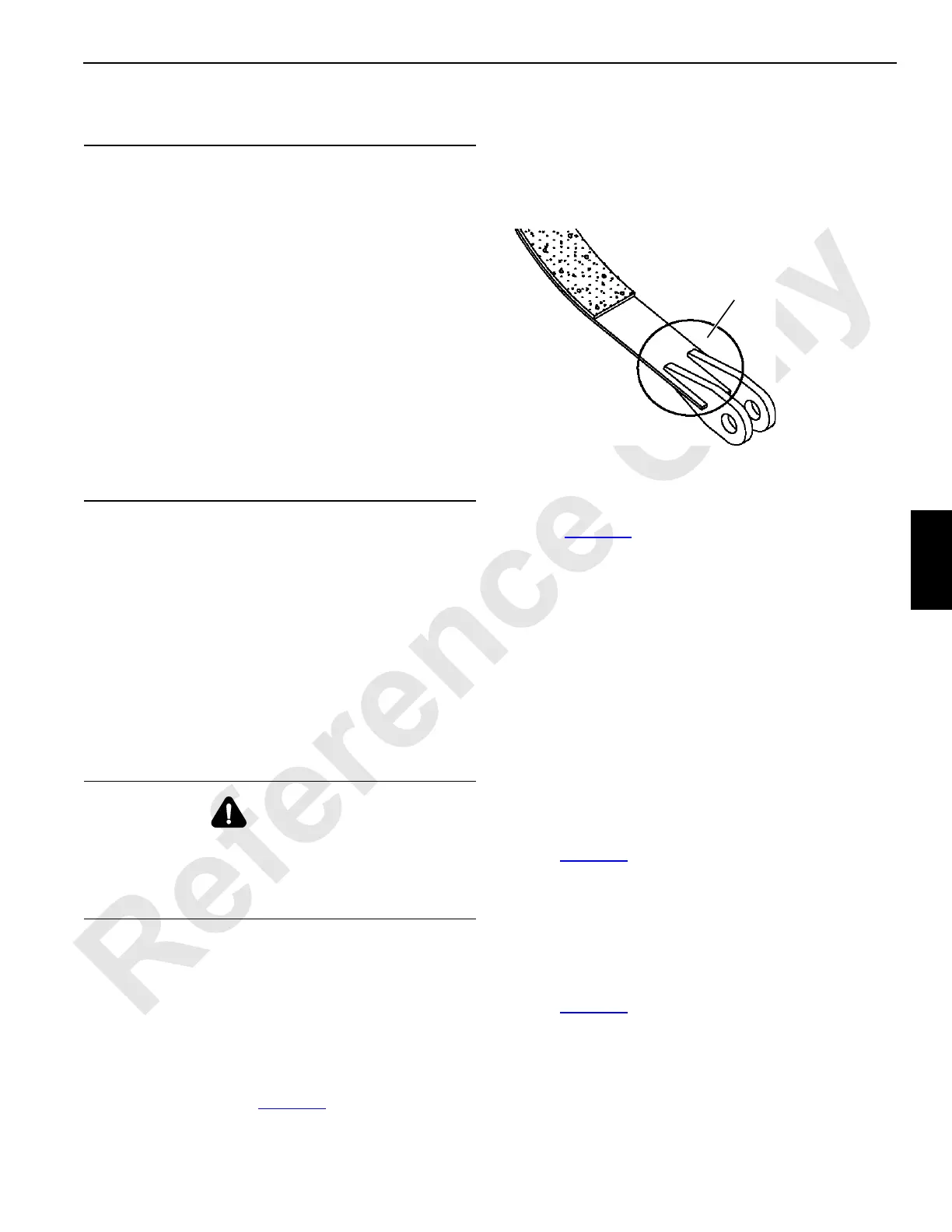

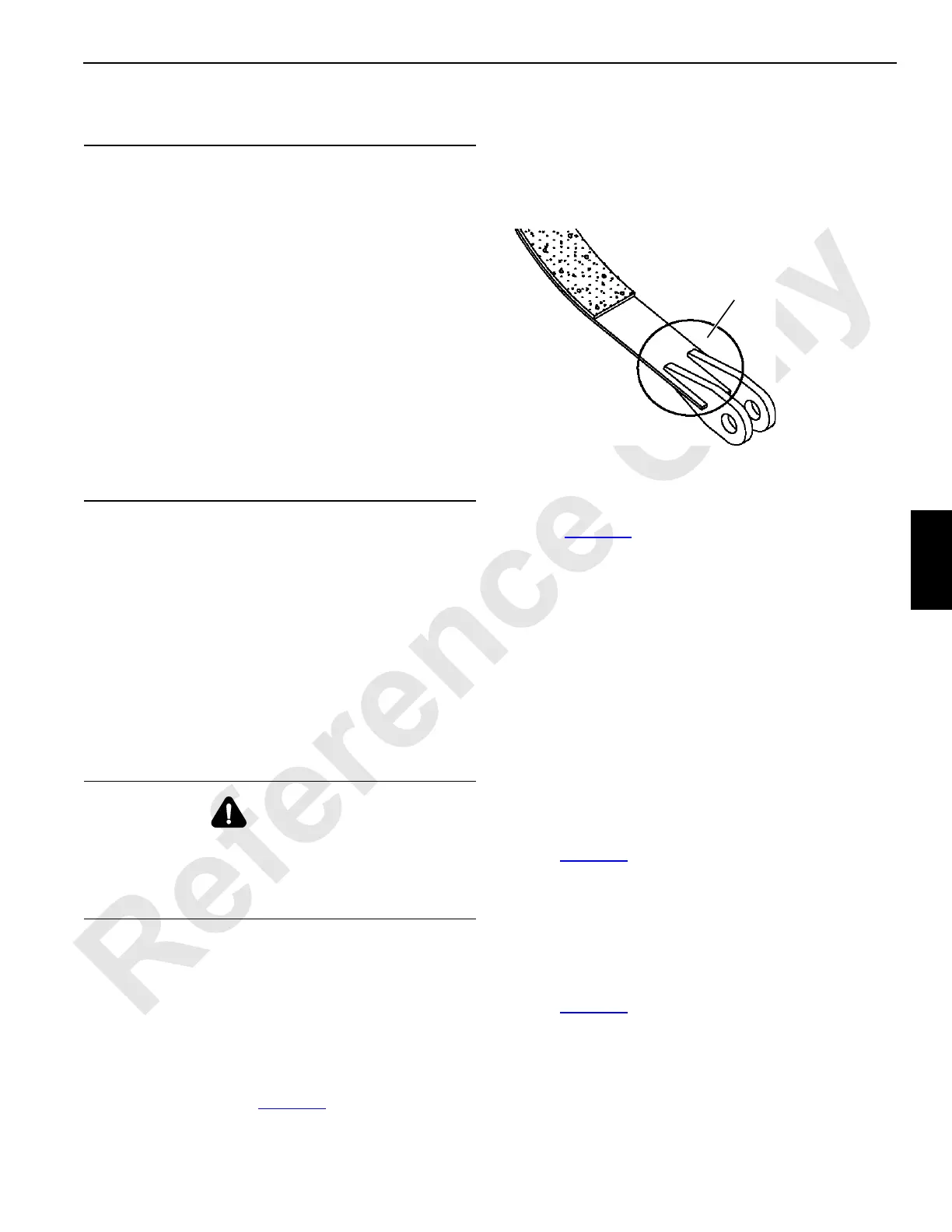

4. Thoroughly inspect the brake bands for cracks and

corrosion when the bands are removed for relining. This

inspection procedure also applies to band assemblies

that are received in exchange for bands that were

removed for relining.

The inspection method must include non-destructive

testing — magnetic particle (MT) or ultrasound (UT).

The primary area to inspect is the dead-end attachment

area on the band (see Figure 5-8

).

If there is evidence of cracks or 10% reduction in area

due to corrosion, destroy and discard the band and

replace with it a new band or a band that has passed

non-destructive test/inspection. Contact your Manitowoc

dealer for brake band thickness. Please have the band

part number available at the time of the request.

5. Perform treadle valve checks and make necessary

adjustments.

6. Check each brake band for proper adjustment as follows

(see Figure 5-7

):

NOTE: Check band adjustment when linings are cold for

lift-crane work or warm from duty-cycle work.

a. Lower load block, weight ball, or bucket to ground

from drum being serviced so wire rope is slack.

b. If equipped with three drums, use drum selector to

select desired rear drum, right or left.

c. Turn on free-fall for drum being serviced.

d. Release drum working brake (brake pedal up fully).

e. Turn on drum park for drum being serviced. Drum

parking brake will spring apply.

f. Check for the following dimension:

Current Production — Measure distance from

bottom of actuator to top of rod end as shown in

Figure 5-7

, View A.

- Dimension must be 2.0 to 2-1/2 in (51 to 64

mm)

- Readjust brake when 2-1/2 in (64 mm) is

reached

Past Production — Measure distance from top of

actuator to washer inside actuator as shown in

Figure 5-7

, View B. Dimension can be measured at

either actuator on drum being serviced.

- Dimension must be 1-9/16 to 2-1/16 in (40 to 52

mm)

CAUTION

Moving Machinery Hazard!

It is necessary to rotate load drum and apply and release

drum parking brake during inspection, adjustment, and

overhaul steps.

Drum brake inspection, adjustment, and overhaul

requires two people: one to operate drum and brake

controls and one to perform inspection, adjustment, and

overhaul steps. Maintain constant communication

between adjuster and operator so drum and brake are not

operated while adjuster is in contact with parts.

Lower load block or weight ball onto ground so wire rope

is slack on drum being serviced.

• Adjuster stay clear of all moving parts while drum and

brake are being operated.

• Operator do not operate drum or brake controls until

adjuster is clear of moving parts.

WARNING

Falling Load Hazard!

Only use Manitowoc original equipment lining. Other

lining may not provide proper brake torque. Brake could

slip, allowing load to drop.

FIGURE 5-8

Primary Inspection Area

Loading...

Loading...