INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-28

Published 11-06-15, Control # 040-13

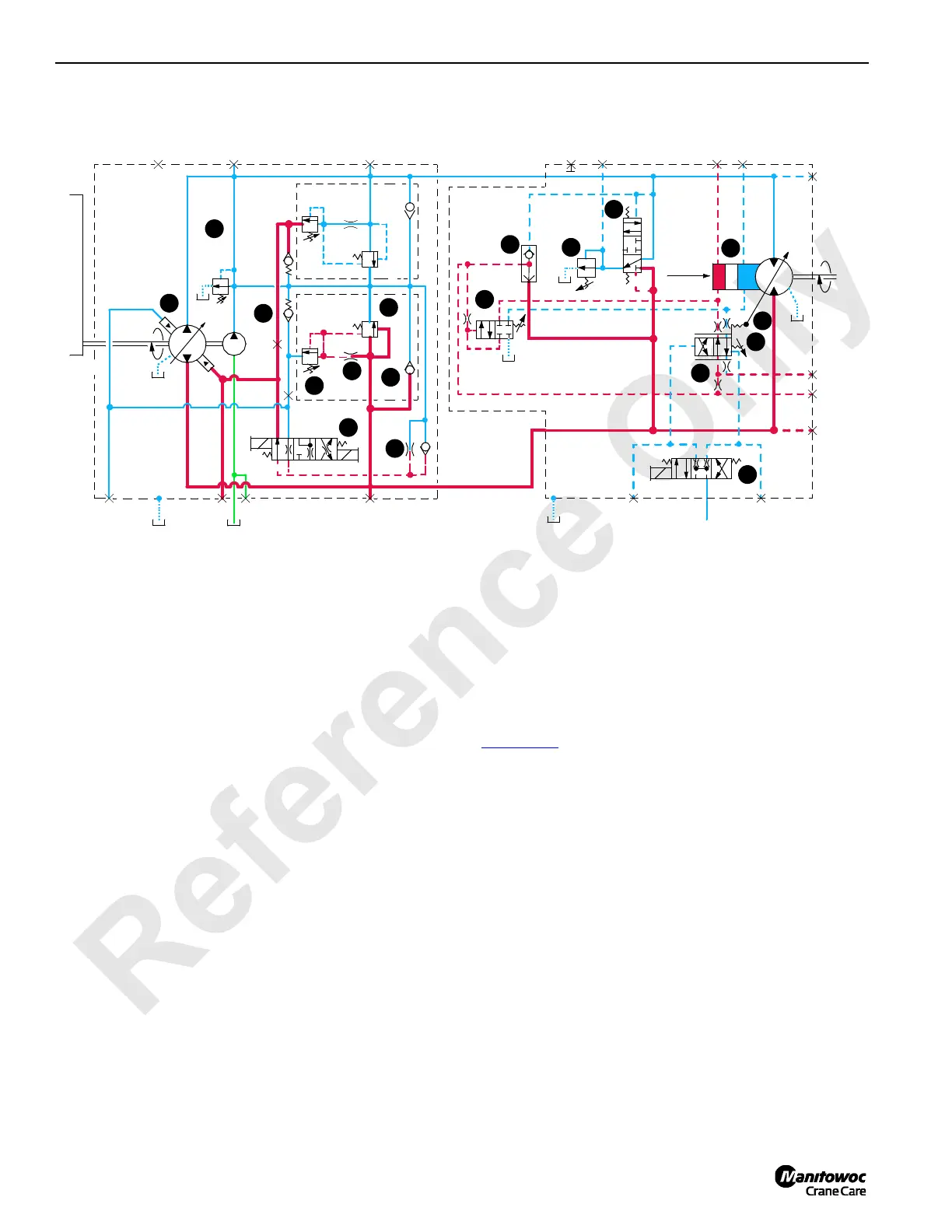

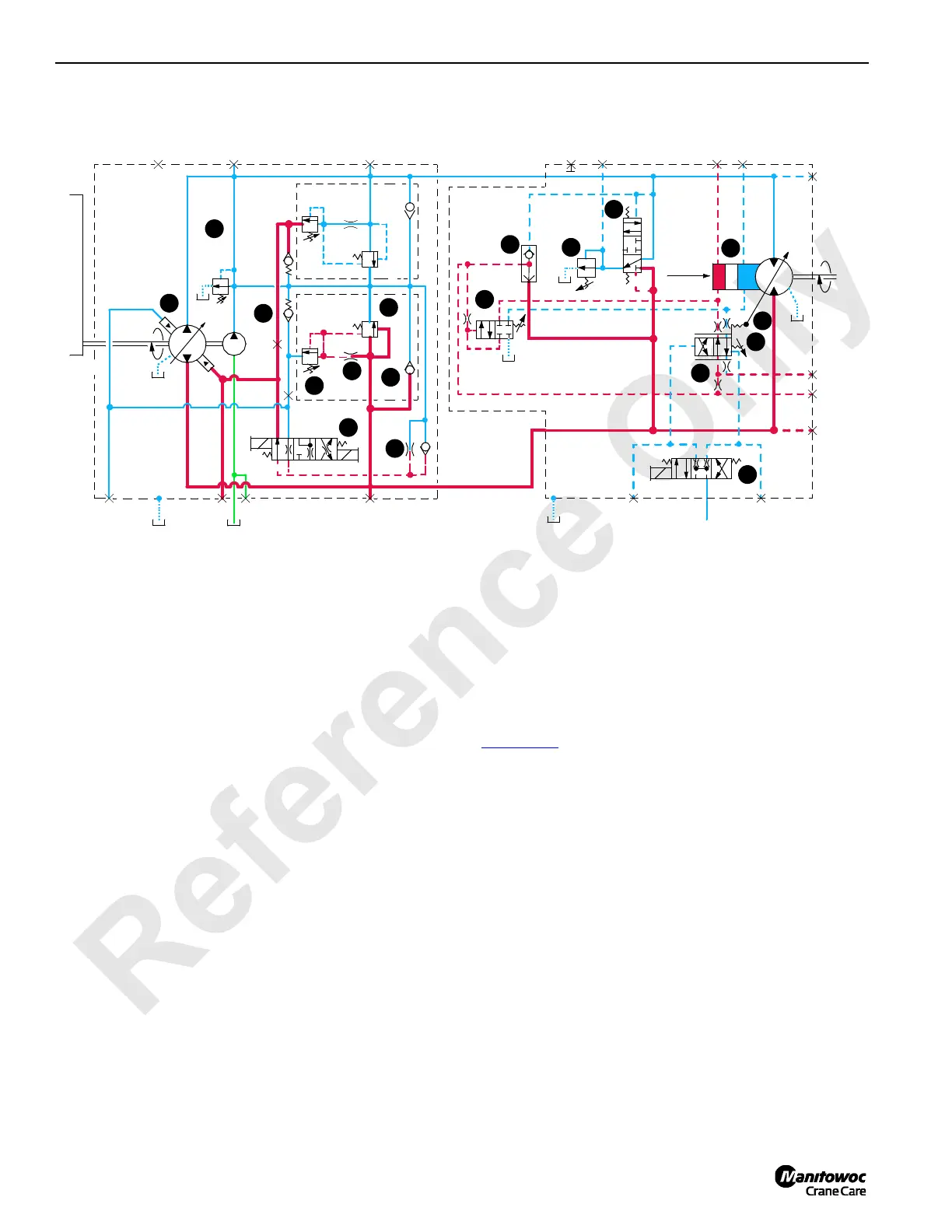

The pressure limiting relief valve (1) serves as pilot valve to

open system relief valve (5) when desired relief pressure

setting is reached. For example, if a pressure imbalance

occurs on both sides of flow restrictor (9), pressure limiting

valve opens and system relief valve relieves system

pressure.

Hydraulic fluid is directed to tank through relief valve (7) or

the flow is transferred to low-pressure side of system through

the make-up check valve (8).

Each variable displacement motor, except travel, begins

operation at maximum displacement (high torque, low

speed) and shifts to minimum displacement (low torque, high

speed) if torque requirement is low. The motor remains in

maximum displacement until servo PC valve (10) receives a

command from PCP valve (11) to direct system pressure and

flow from shuttle valve (12) to minimum displacement side of

servo cylinder (13) that shifts motor.

As PCP valve opens in proportion to output voltage received

from the PC, pilot line pressure is directed to shift servo PC

valve. After overcoming adjustable valve spring (14) and

valve spring (15), servo PC valve shifts and directs fluid to

stroke motor at minimum displacement output. If the load at

the motor shaft increases, force on adjustable valve spring

increases. This shifts servo PC valve to de-stroke the motor

to maximum displacement for safe load handling.

Optional drum 1 motor, boom hoist motor, and the single

motor drive for split rear drum, also have a PCOR (Pressure

Compensating Over-Ride) valve (16) that is enabled when

system pressure of 4,930 psi (340 bar) is reached. When

system pressure exceeds the PCOR setting, the valve shifts

to direct flow from shuttle valve into maximum displacement

side of servo cylinder.

The PCOR valve over-rides the command from servo PC

valve, increasing motor displacement and output torque and

reducing output speed. When PCOR valve closes, control of

the motor returns to servo PC valve.

The Optional dual motor drive for split rear drum shaft

(Figure 1-29

) has one bi-directional, variable displacement

motor with 12 volt proportional solenoid control along with

one fixed displacement motor mounted in tandem.

Proportional motor displacement is set to override to

maximum (high torque) at 4,500 psi (310 bar) preventing

high pressure motor failure.

The travel motor servo is opposite of other system motors.

The travel variable displacement motors begin operation at

minimum displacement (low torque, high speed). The motor

shifts to maximum displacement (high torque, low speed)

when starting torque is required and back to minimum

displacement when in motion if load is below a preset

pressure of 3,770 psi (260 bar). Depending on motor system,

servo uses internally or externally supplied pressure to

perform the shifting operation. Servo control fluid is supplied

from high-pressure line of motor port A or B and shifts shuttle

valve and servo control valve before entering servo cylinder.

Continuous changing of closed-loop fluid occurs through

leakage in pumps, motors, and loop flushing valves.

RF-03

FIGURE 1-12

(23 bar)

340 PSI

T2

T3

A

MAX.

P

U

M

P

D

R

I

V

E

B

B

A

A

DC

EGFD

OUTPUT

INPUT

PUMP

MOTOR

B

A

M8

M7

M3M4M6L2

M9

M2

M5

M1

11

4

6

18

13

5

10

9

15

14

7

16

12

17

2

1

8

3

DISP.

T1

Loading...

Loading...